Sagetown

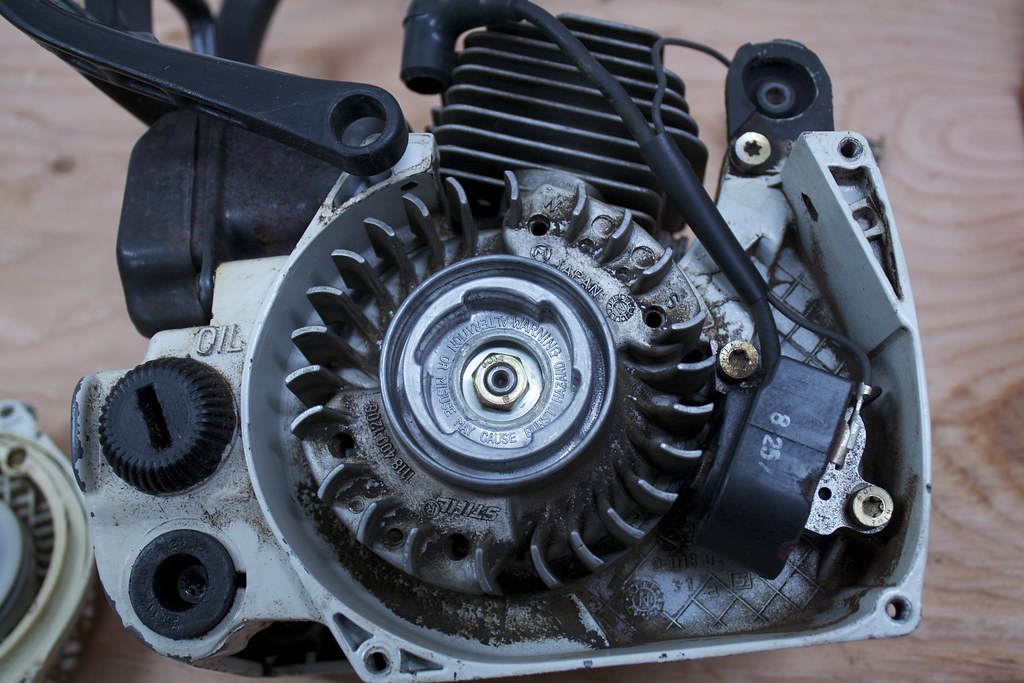

Farmer and a STIHL

Generally an old used saw may need nothing more than replacing the fuel and impulse hoses to get it running again.

Go ahead and change out that impulse hose before you go any farther. Use a pair of long needle nose pliers. I believe you've already said you replaced the fuel hose, so you should be good there. Make sure the fuel filter is resting in its proper place in the tank.

Hope you get it going w/o any other problems...

Go ahead and change out that impulse hose before you go any farther. Use a pair of long needle nose pliers. I believe you've already said you replaced the fuel hose, so you should be good there. Make sure the fuel filter is resting in its proper place in the tank.

Hope you get it going w/o any other problems...