Hey Brad BTW was that the saw that went on Canton CL the other day and gone in a few hours?

No. I bought it less than 10 miles from home here.

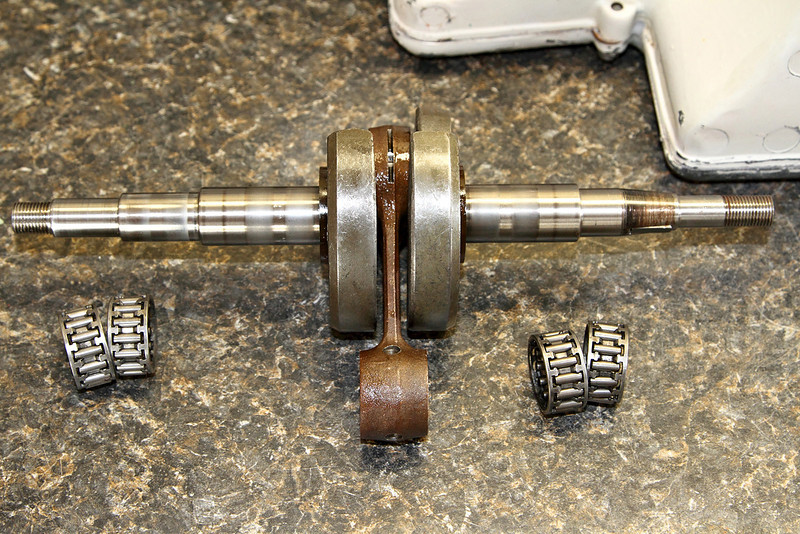

Thanks Leeha. I went ahead and bought a new OEM piston and rings for it. Now I need a couple clutch shoes. They're missing the linings. If I had the piston and crank seals, I'd have this thing running today. Oh well, guess it'll be next week sometime now.

Last edited:

That truly is a beast of a stihl though

That truly is a beast of a stihl though