Sierra_rider

Piss revver

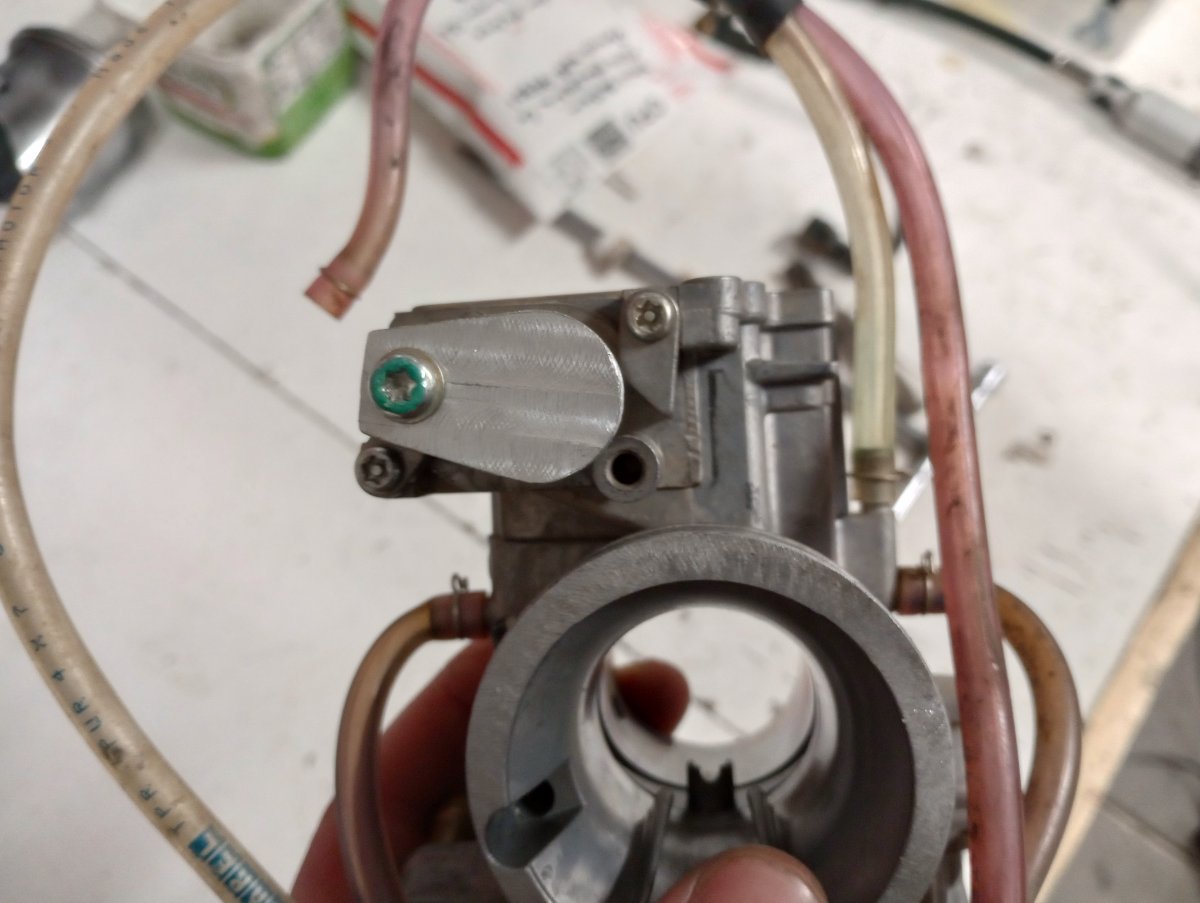

Finished the porting and head work on the bike. The head is tricky, as I had to take some material out of the chamber too...it's kinda the opposite of saw building. On saws, we're usually trying to shrink the chamber...on the bikes, you end up with too much compression if you just correct for squish...so you end up milling the chamber too.