Mastermind

Work Saw Specialist

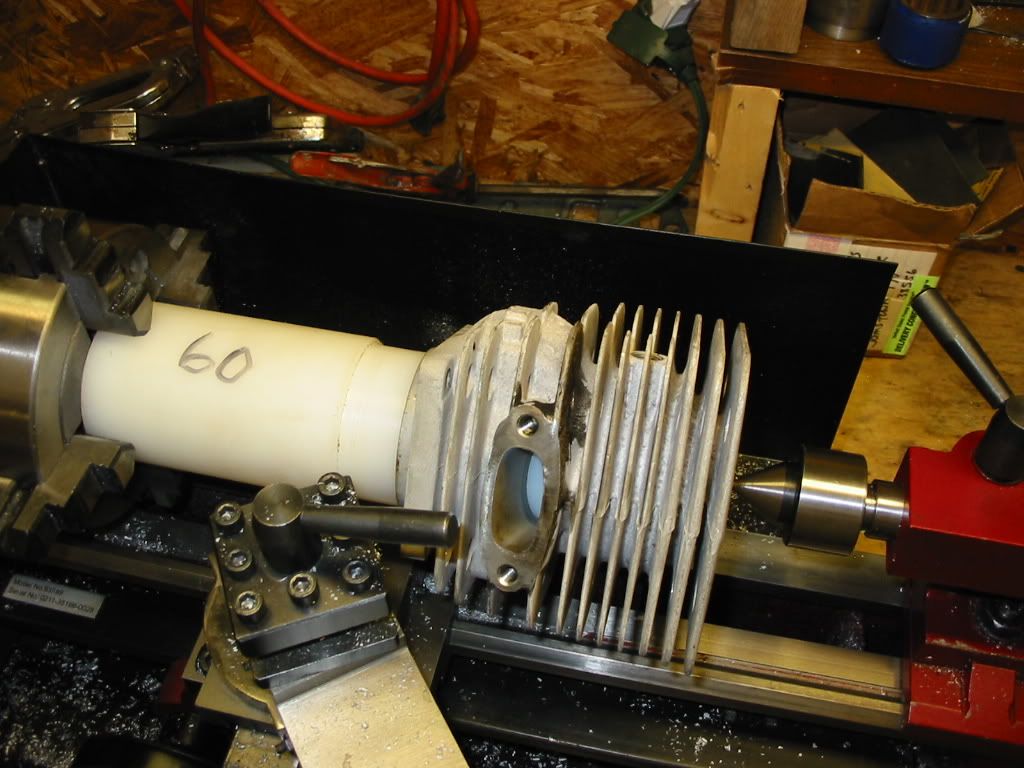

Here we go folks. A brand spanking new 3120....

First things first......this green coil must go.

We replaced it with a 272XP coil.

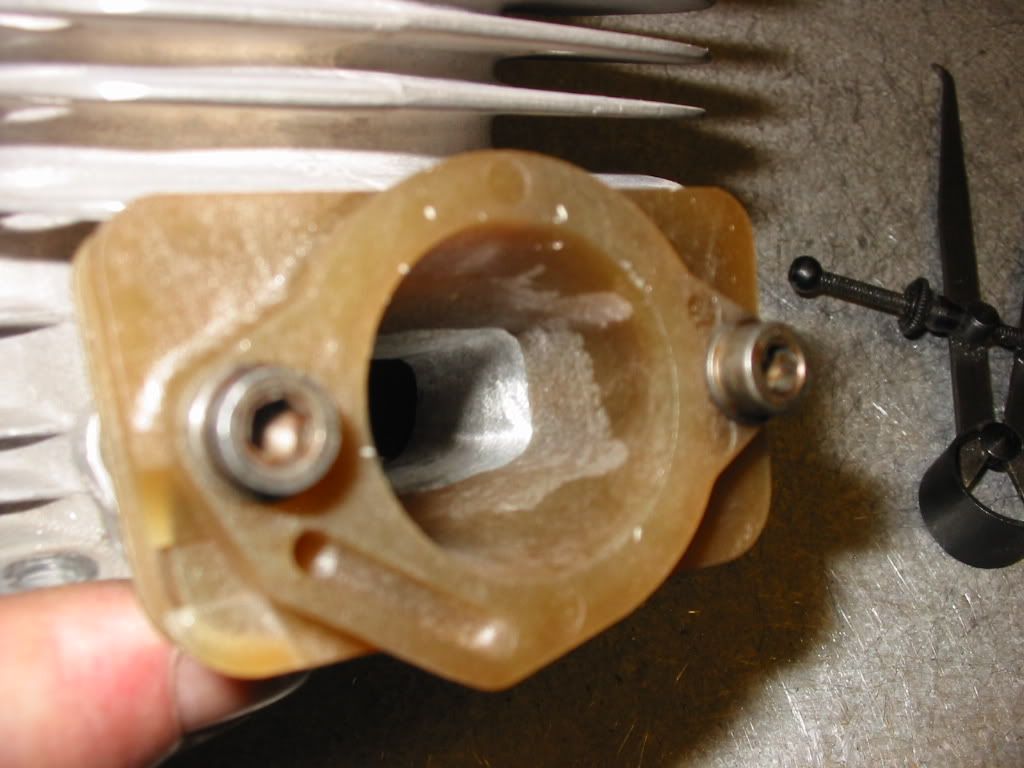

Then we had Bertrand add a high side metering adjustment screw to the carb. As you can see the air filter base must be modified to clear the screw.

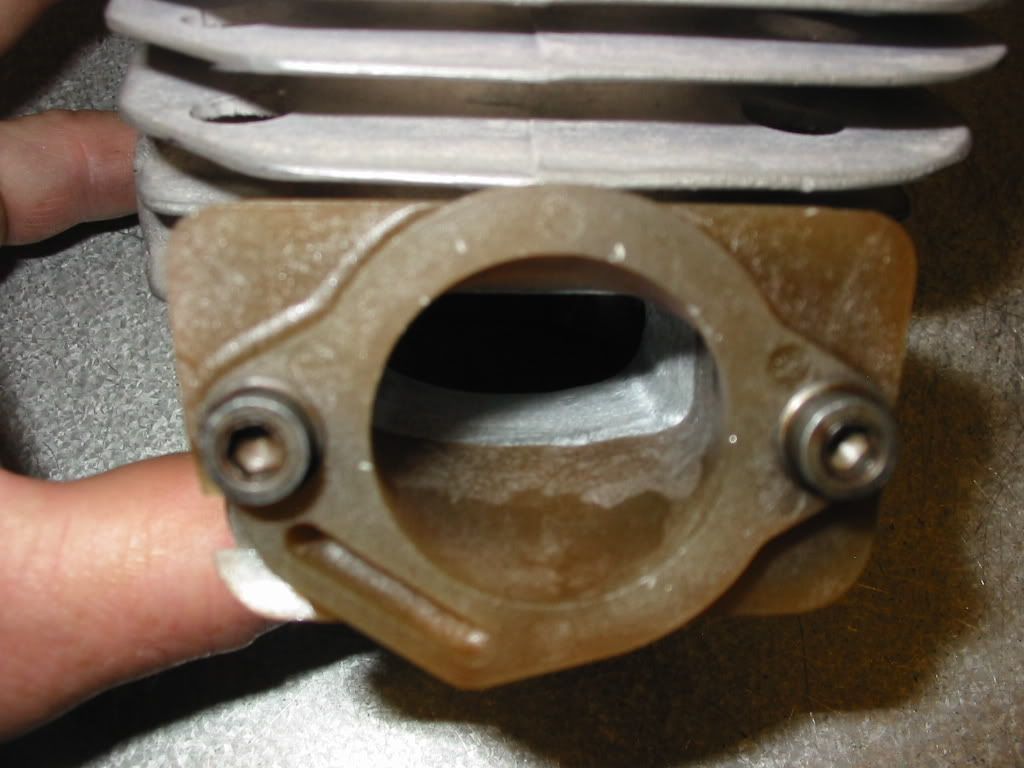

We need to open that up some......huh?

First things first......this green coil must go.

We replaced it with a 272XP coil.

Then we had Bertrand add a high side metering adjustment screw to the carb. As you can see the air filter base must be modified to clear the screw.

We need to open that up some......huh?