Can you run the stock carb and jets with a mod like this?

No problem at all.

Can you run the stock carb and jets with a mod like this?

Just make sure not to go too wide, I've been doing it in stages, sliding the cylinder on and checking skirt clearance.

I am on my first port job. I have been needing help and finally found this post.

What is the "Skirt Clearance" exactly?:help:

That is from the edge of the port to the edge of the piston. keep it no less then .100" for normal work saws.

just kidding.

just kidding.Ok Parrisw, so from the very bottom of the piston is the skirt. That makes sense because it does go down off the top of the piston like a skirt and I do refer to her as a female. I guess if a girl was running the saw she would refer to her saw as a male and she could call the skirt a kilt :kilt: loljust kidding.

So the clearance between the skirt to the top edge of the intake port should be no less then .100" for normal working saws.

Correct?

Thank You for your Time :Eye:

No, the skirt edge!! to the side of the port. not the bottom of the piston, the sides of the piston. The skirt edge should go past the edge of the port .100"

Maybe you misunderstood my last post?

Maybe you misunderstood my last post?So, the bottom edge of the piston should hang down covering the intake port by .100 restricting the flow :jawdrop:

Maybe you misunderstood my last post?

Thank you for taking the time to provide me with the links. I found them to be very informational, I'm stihl learning.

:newbie:

Just wide enough to fit the paper in. It's not critical at all.

thank you very much for the reply.

i will widen some. im just gona grind till i think it looks good and call it good. i just ground till it looked good on my 359 twice. think it might have a 3rd time comeing when i get bored

i have the cylinder here and man im lookin at the upper tranfer and ill leave it alone i can see me accidntly getn the cylinder wall. need little 45deg angle grinder it looks like

thank you again for the reply

thanks

Evan

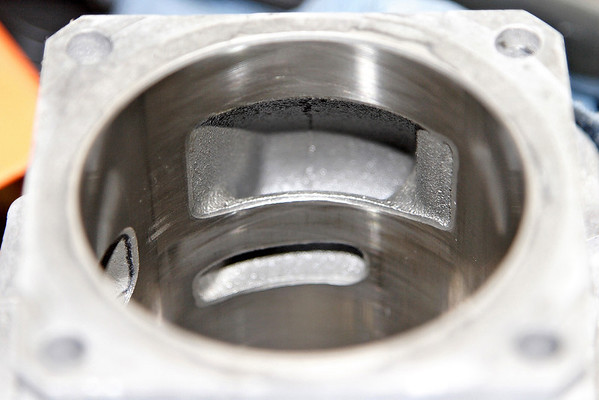

Before

Do not take it out "into" the bottom flange. Just taper it to it. You really wouldn't even have to go that far. Just remove the lip often found at the bottom of the transfer and taper it a little to promote flow.

Quick question for the experienced guys...

Comparing this to the 066 jug that I have, the edge of the lower transfer on the right hand side in the pic above is much further away from the edge of where the skirt rides. It seems like the lower transfer is essentially centered between the edges of the skirts, which would seem to force the charge to essentially travel straight "up", then get turned towards the intake side by the upper transfer.

Do you think there's anything to be gained by blending the lower part of the lower transfer down and towards the exhaust side, essentially allowing for a more straight line shot to the upper transfer?

I know, I know, n00bs shouldn't touch the transfers - I'm just thinking out loud here..

Enter your email address to join: