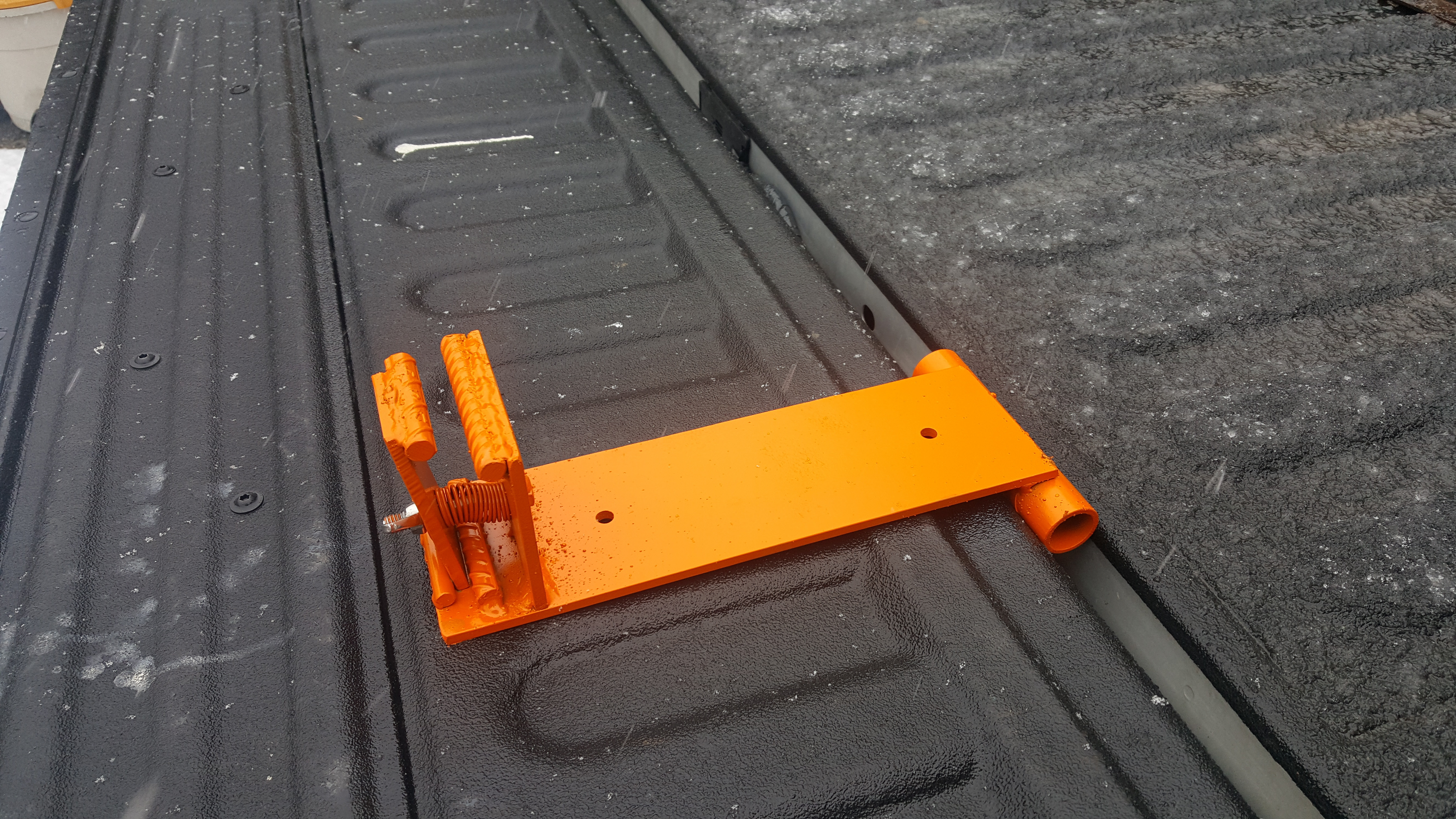

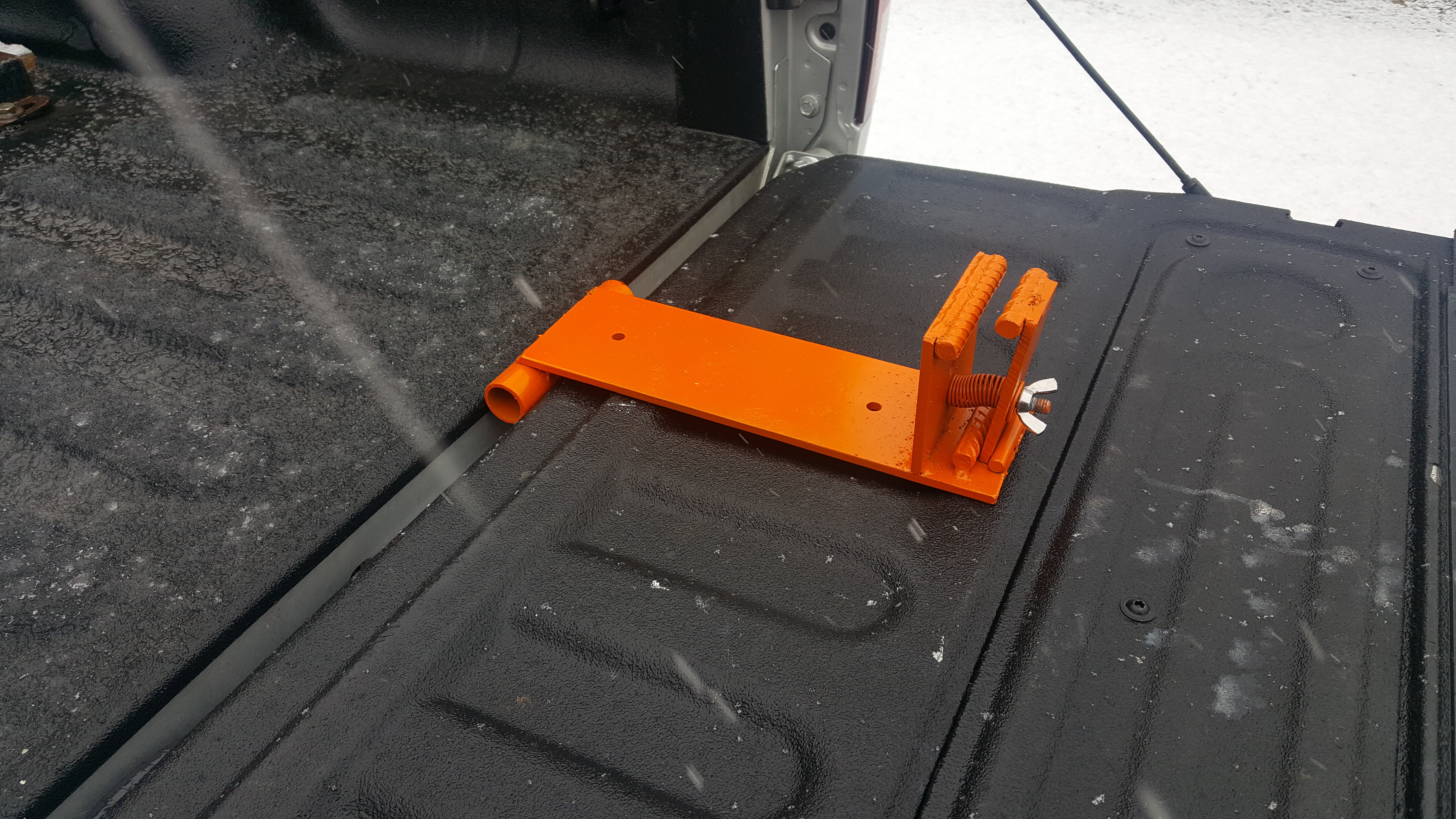

I got sick of sharpening my saw on the tailgate using the cable as a support.

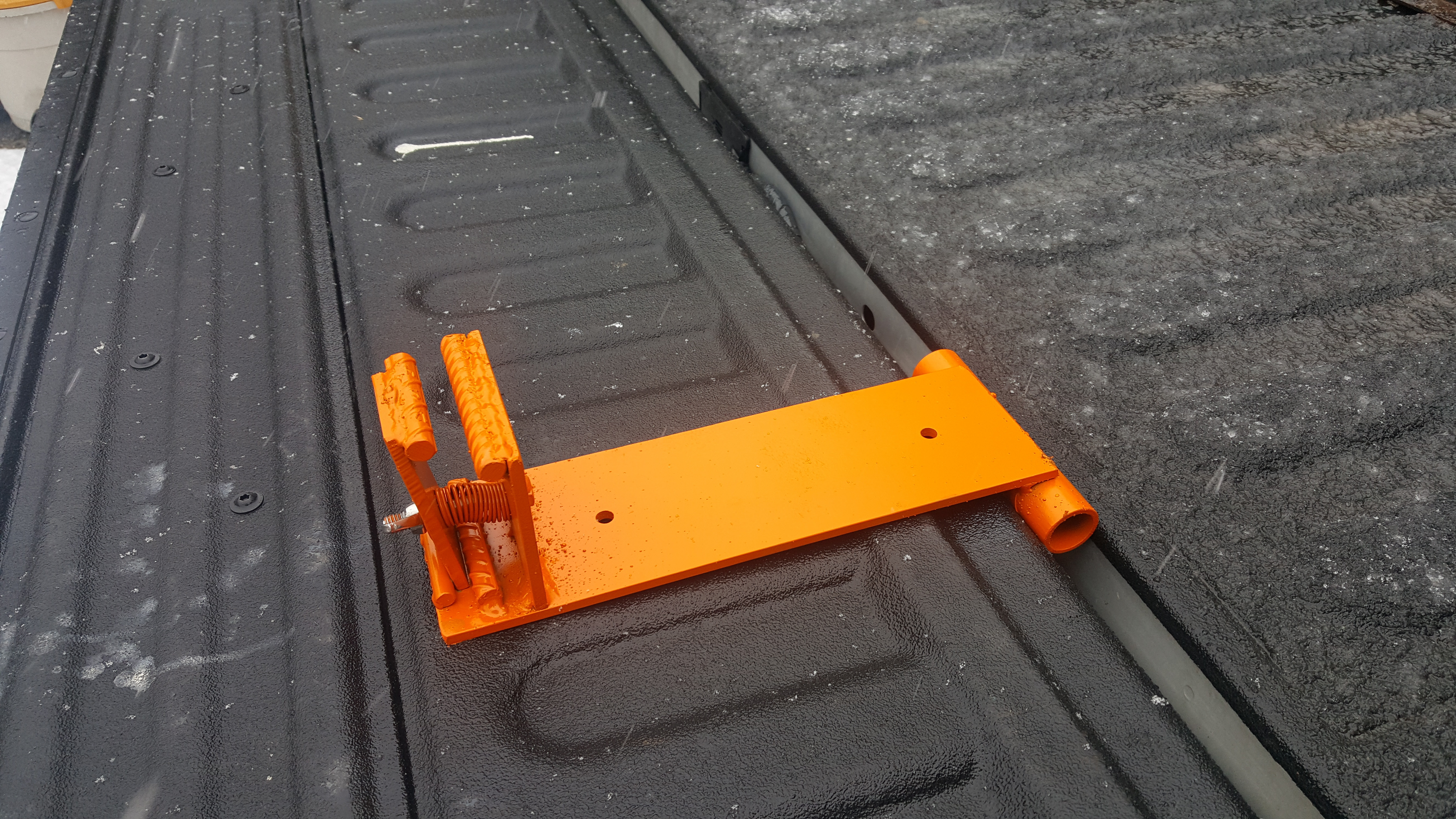

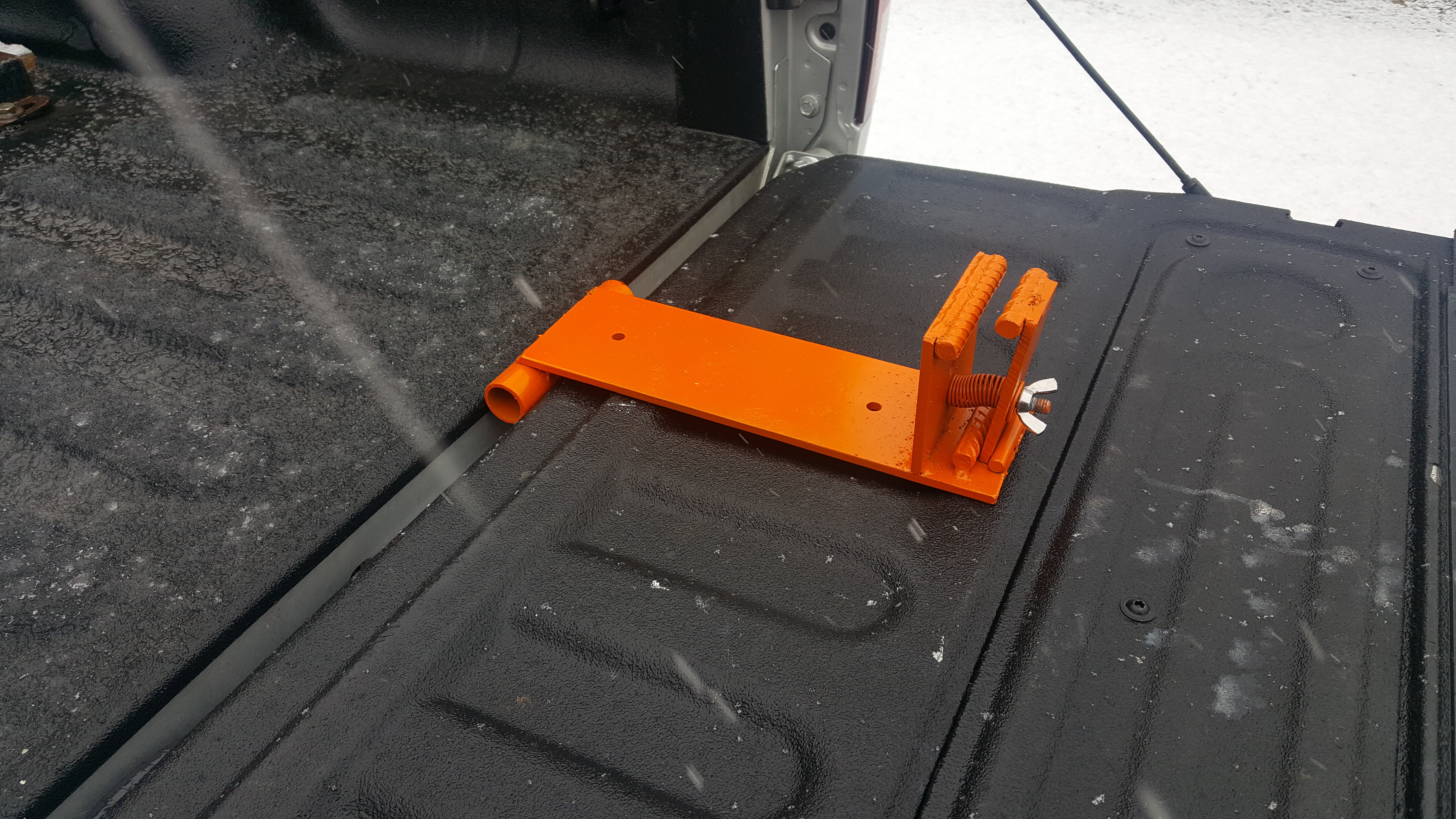

This fit's in the space between the bed and the tailgate.

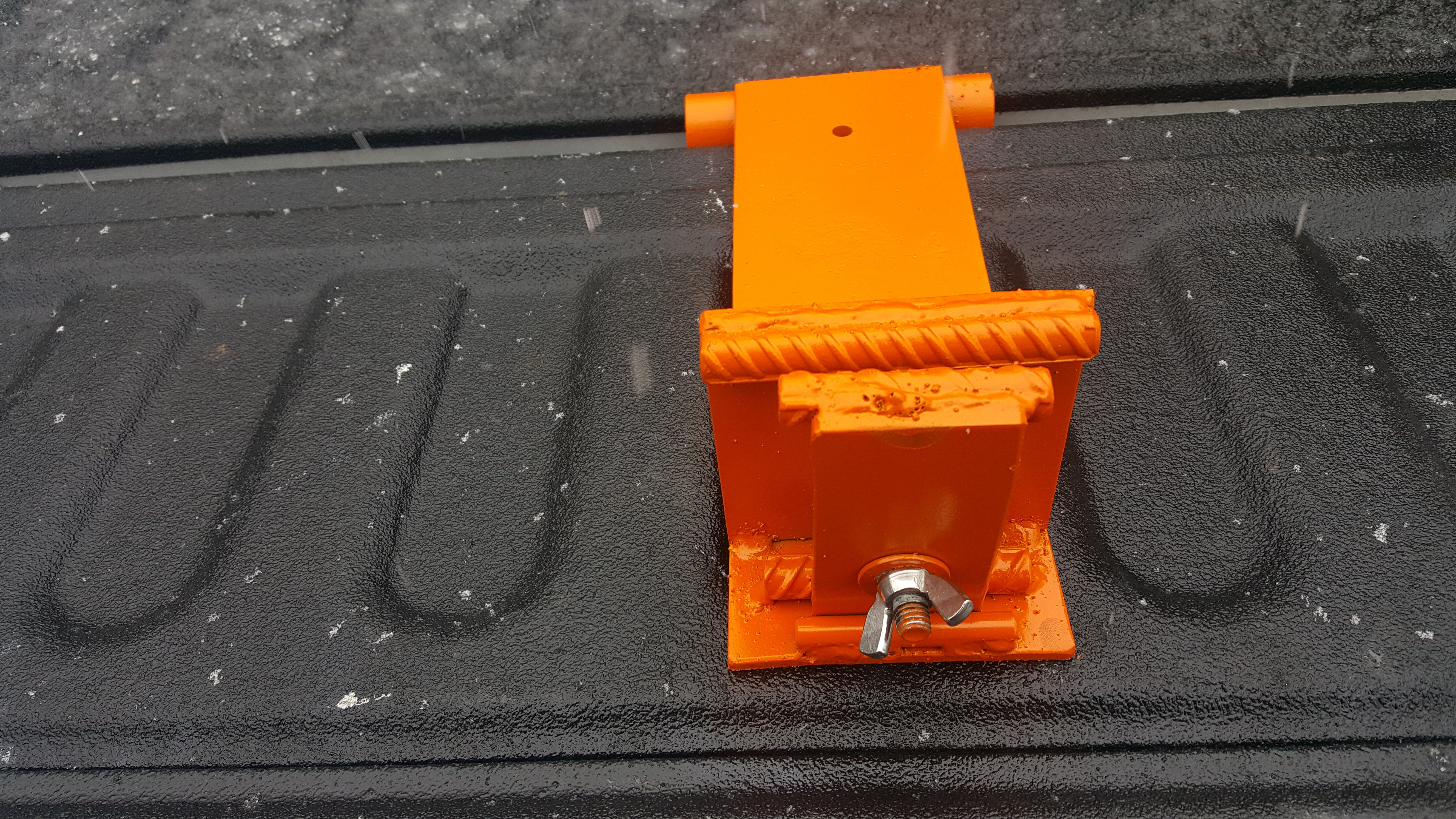

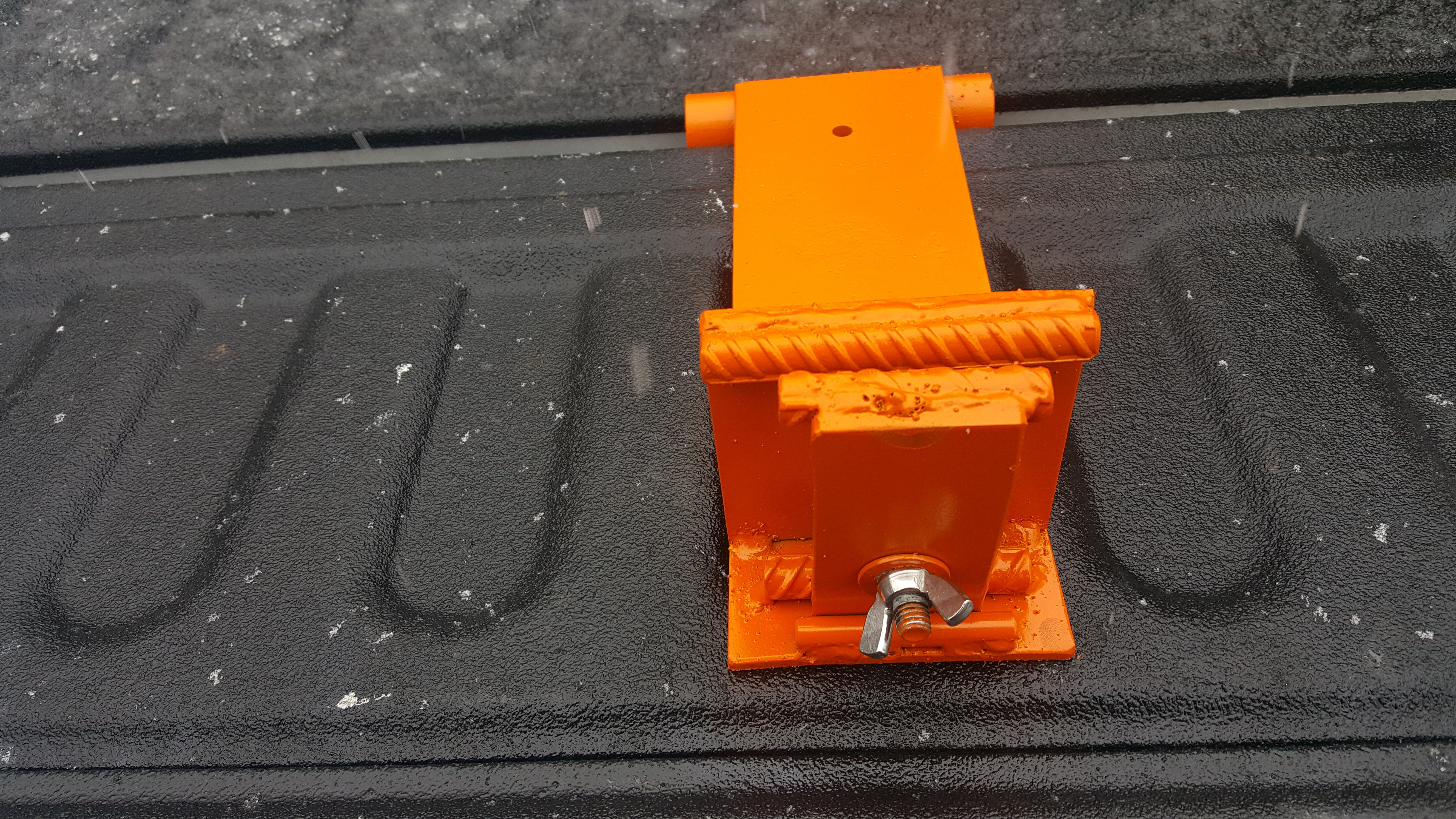

I've already replaced the wingnut with a coupler and a piece of 3/8 round welded on for a T handle, much more leverage.

This fit's in the space between the bed and the tailgate.

I've already replaced the wingnut with a coupler and a piece of 3/8 round welded on for a T handle, much more leverage.