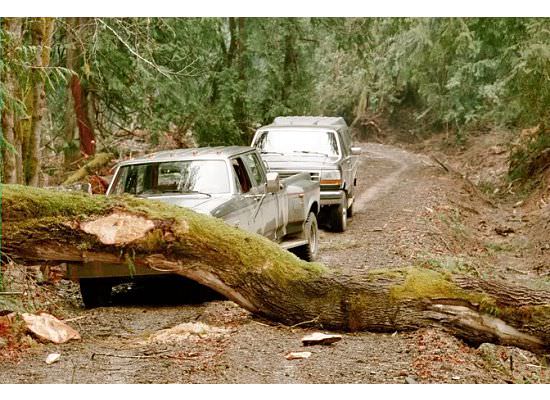

So many potential trees to mill...so little time.....

Before i even ask the question, I will start by saying that i expect to get answers like: "it depends", "mill all of them", "no way to tell till you open them up", "can't judge a book by it's cover", "depends on what your market/customers want" etc etc etc....

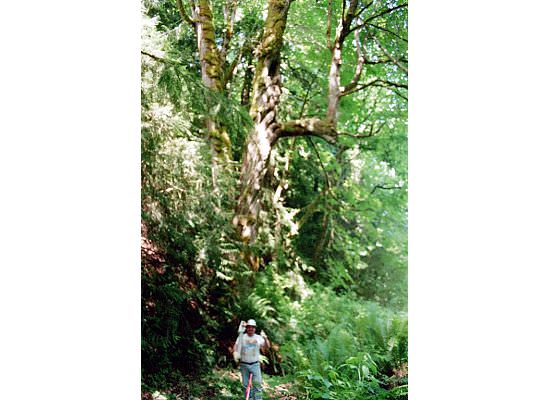

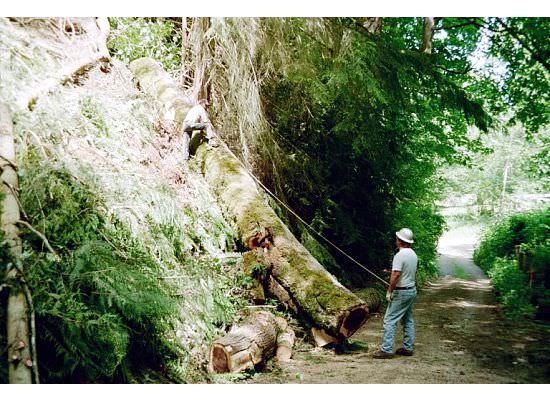

But I'll ask anyway....has anyone ever figured out how to "read" a tree and have an idea that it will be "worth" milling? For "worth" in this case, I'm defining it as unique wood, grain pattern, color and other features that may add value to a natural type live edge slab. I'm not talking about grade and clear type lumber.

I assume knots and burl type features on the outside and crotches indicate "features " inside, but does anyone have any insight on other stuff to look for? Any trends on how/ where the tree was growing affects inside? For instance, on a you tube sawing vid i watched, the guy talked about creek bank walnut having more color (it seemed to him, in his experience).

Just wondering if all your experience has pointed you in any direction as to what to saw, or if everyone just saws whatever they get their hands on...

Before i even ask the question, I will start by saying that i expect to get answers like: "it depends", "mill all of them", "no way to tell till you open them up", "can't judge a book by it's cover", "depends on what your market/customers want" etc etc etc....

But I'll ask anyway....has anyone ever figured out how to "read" a tree and have an idea that it will be "worth" milling? For "worth" in this case, I'm defining it as unique wood, grain pattern, color and other features that may add value to a natural type live edge slab. I'm not talking about grade and clear type lumber.

I assume knots and burl type features on the outside and crotches indicate "features " inside, but does anyone have any insight on other stuff to look for? Any trends on how/ where the tree was growing affects inside? For instance, on a you tube sawing vid i watched, the guy talked about creek bank walnut having more color (it seemed to him, in his experience).

Just wondering if all your experience has pointed you in any direction as to what to saw, or if everyone just saws whatever they get their hands on...