timberwolf

Addicted to ArboristSite

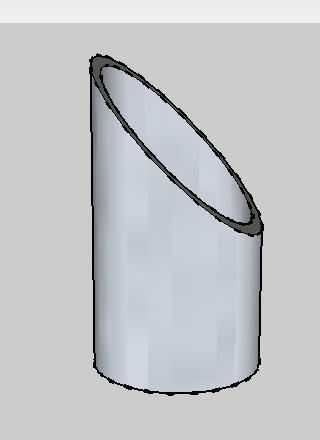

Yes for a tube, for an orifice in thin plate no.

Problem is in smaller holes the thickness of plate in relation to the diamiter of the hole changes the coefficient of discharge to a greater extent than how much the wetted perimiter effects the total flow.

When the radius of the hole is only a few times greater than the tickness of the plate the coefficient of discharge starts to head more towards 0.75 instead of 0.60.

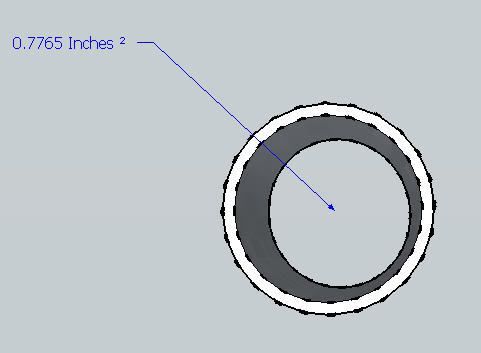

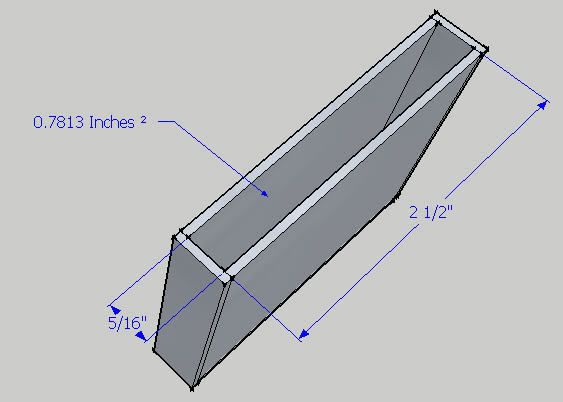

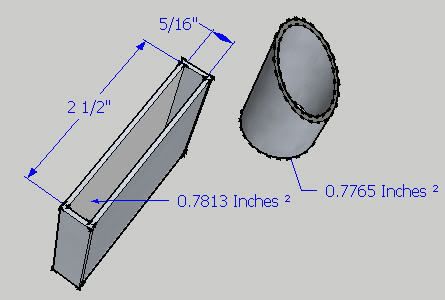

I even found that a thin slot with the same area as a circle flowed as much or more than the circle. in theroy looking at the wetted perimiter this should not be. However an orifice shaped as a thin slot in thin plate is squeezed between two edges that have a high relative thickness compaired to the width of the opening raising the coefficient of discharge.

I would not have though this would be, more wetted perimitter should be less flow from a simple logical prespective, but like I said putting this to test on a flow bench has taught me otherwise. In some cases esp in smaller openings coefficient of discharge is a bigger factor than wetted perimiter.

Problem is in smaller holes the thickness of plate in relation to the diamiter of the hole changes the coefficient of discharge to a greater extent than how much the wetted perimiter effects the total flow.

When the radius of the hole is only a few times greater than the tickness of the plate the coefficient of discharge starts to head more towards 0.75 instead of 0.60.

I even found that a thin slot with the same area as a circle flowed as much or more than the circle. in theroy looking at the wetted perimiter this should not be. However an orifice shaped as a thin slot in thin plate is squeezed between two edges that have a high relative thickness compaired to the width of the opening raising the coefficient of discharge.

I would not have though this would be, more wetted perimitter should be less flow from a simple logical prespective, but like I said putting this to test on a flow bench has taught me otherwise. In some cases esp in smaller openings coefficient of discharge is a bigger factor than wetted perimiter.

Last edited: