Rudolf73

Addicted to ArboristSite

Cheers Rick!

You sir are a freakin rocket scientist. Excellent work bro...

Loco

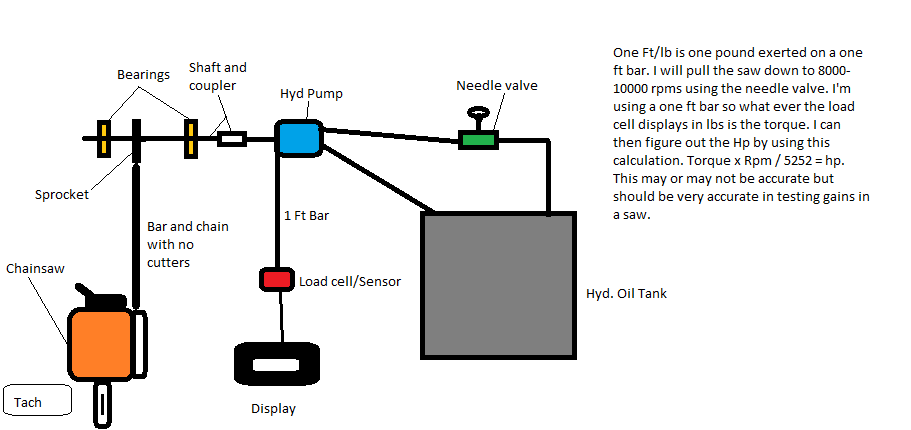

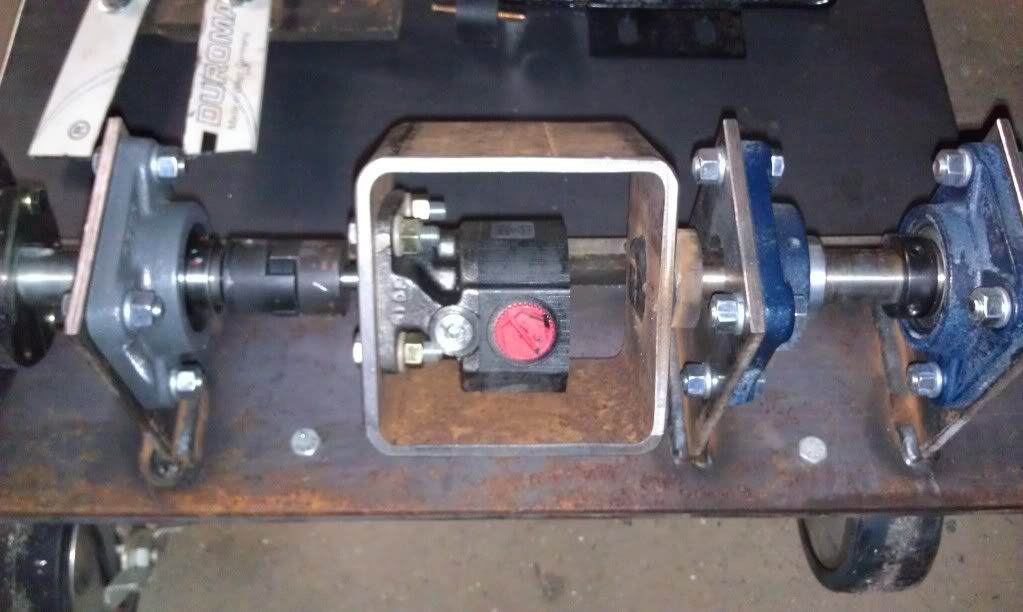

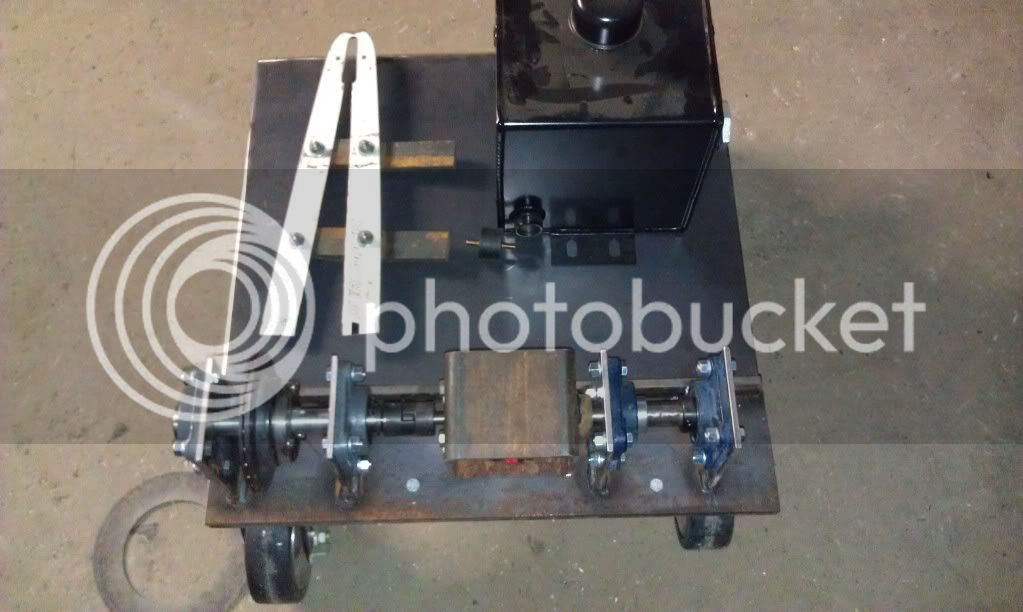

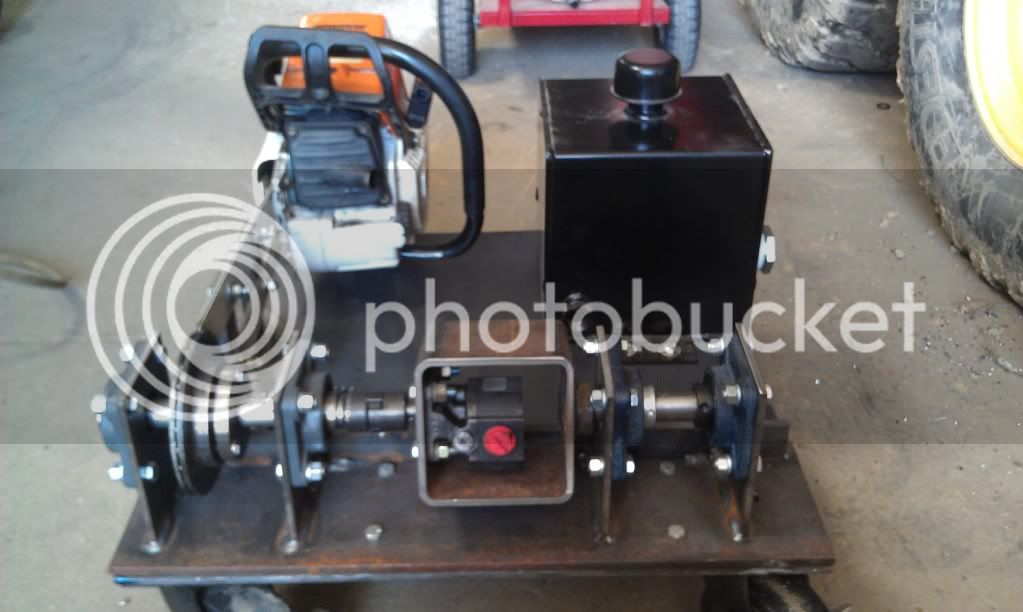

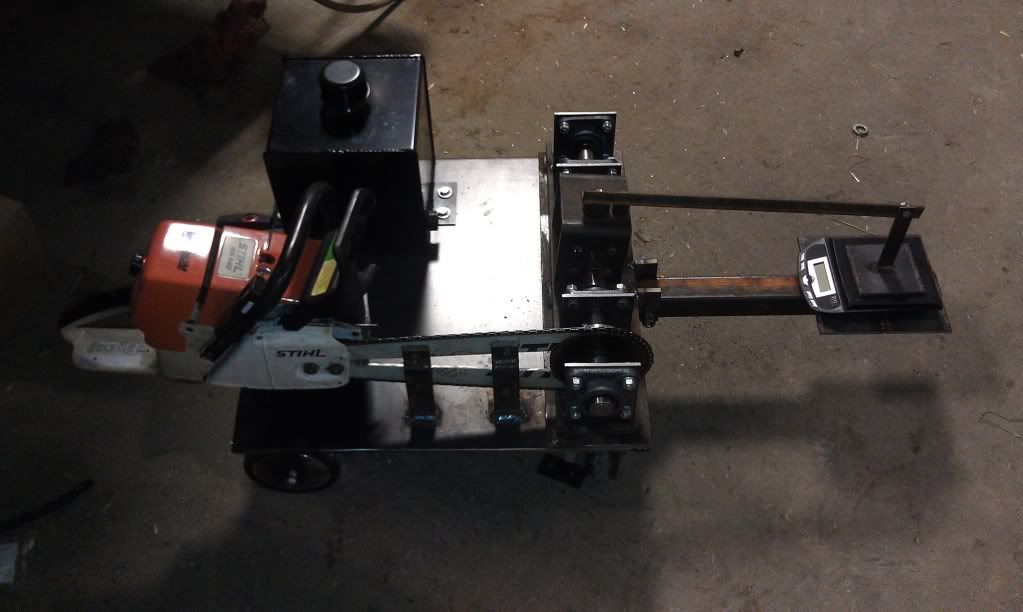

Got the dyno done for the most part. I have lots of pictures of the build and a video of a MS 460 begging for mercy.

Shouldn't you retune if you pop of the air filter? I have a feeling that the .3hp ain't just from better air flow. It's also from making the saw run leaner.

Shouldn't you retune if you pop of the air filter? I have a feeling that the .3hp ain't just from better air flow. It's also from making the saw run leaner.

I dis-agree. If the saw is sucking more air and has become leaner then if you richen it up with more air, will that not give more fuel air mixture and more horsepower. That is what this dyno will prove, no more speculation.

I dis-agree. If the saw is sucking more air and has become leaner then if you richen it up with more air, will that not give more fuel air mixture and more horsepower.

If the saw is pulling more air, it will also pull more fuel.

More air doesn't enrich an already lean air to fuel mixture. And while a saw may suck more fuel (to an extent) due to the removal of the air filter, it may not suck enough to compensate for the additional airflow into the system (depending on the tuning at the time), thereby most likely resulting in a lean condition....same as any additional source of air introduced to the system not compensated for by adjusting the mixture accordingly. And yeah, it may scream under those conditions...until the piston melts down.

Conversely, a completely funky air filter whose lack of airflow has been compensated for by leaner and leaner tuning over time will certainly create a severely lean condition if replaced by a new/clean air filter...and probably burn up the top end if the mix isn't re-enriched enough to compensate for all the "new" air.

Too much air is too much air if not compensated for regardless of the source.

But back to the dyno!!!

Couple of questions 1) Are you taking into account the gear reduction on your sprockets? 2) By what I can see some of your fluid heat is coming from the way that exhaust outlet is pointing or so it appears from here

Except if you have more air through the venturi of a carb it will pass over the jets and pull more fuel.

I know that the saw was not to lean because it had the four strokin still going on with no load. It probably made it a little more lean but not enough to hurt anything as I tend to tune em a little on the fat side now anyway. I'll get a video tommorow of the saw running with the air filtr on and off.

I was just stunned to see the results in front of me when the air filter was pulled off while the saw was held at 9000 rpms.

This is exactly what i was trying to point out, and one thing the dyno can't help you with if you test it with a single tuning. Tune it fat once, lean the other time, just right the third you should get different results from the same saw. If you had the saw running fat, pulling off the filter maybe just made the perfect fuel/air mixture. If it wasn't too lean when you removed the filter then you were definitely running her way fat. Have you tried runing it with the filter and tuning it a bit leaner? You would probably get similair (altho probably a bit lesser) results.

Im thinking you should actually use the dyno to find the sweet spot while tuning at WOT for every change you make. Only then the data would be objective which is the purpose of dyno testing in the first place

Enter your email address to join: