Magnumitis

ArboristSite Operative

- Joined

- Nov 24, 2012

- Messages

- 379

- Reaction score

- 415

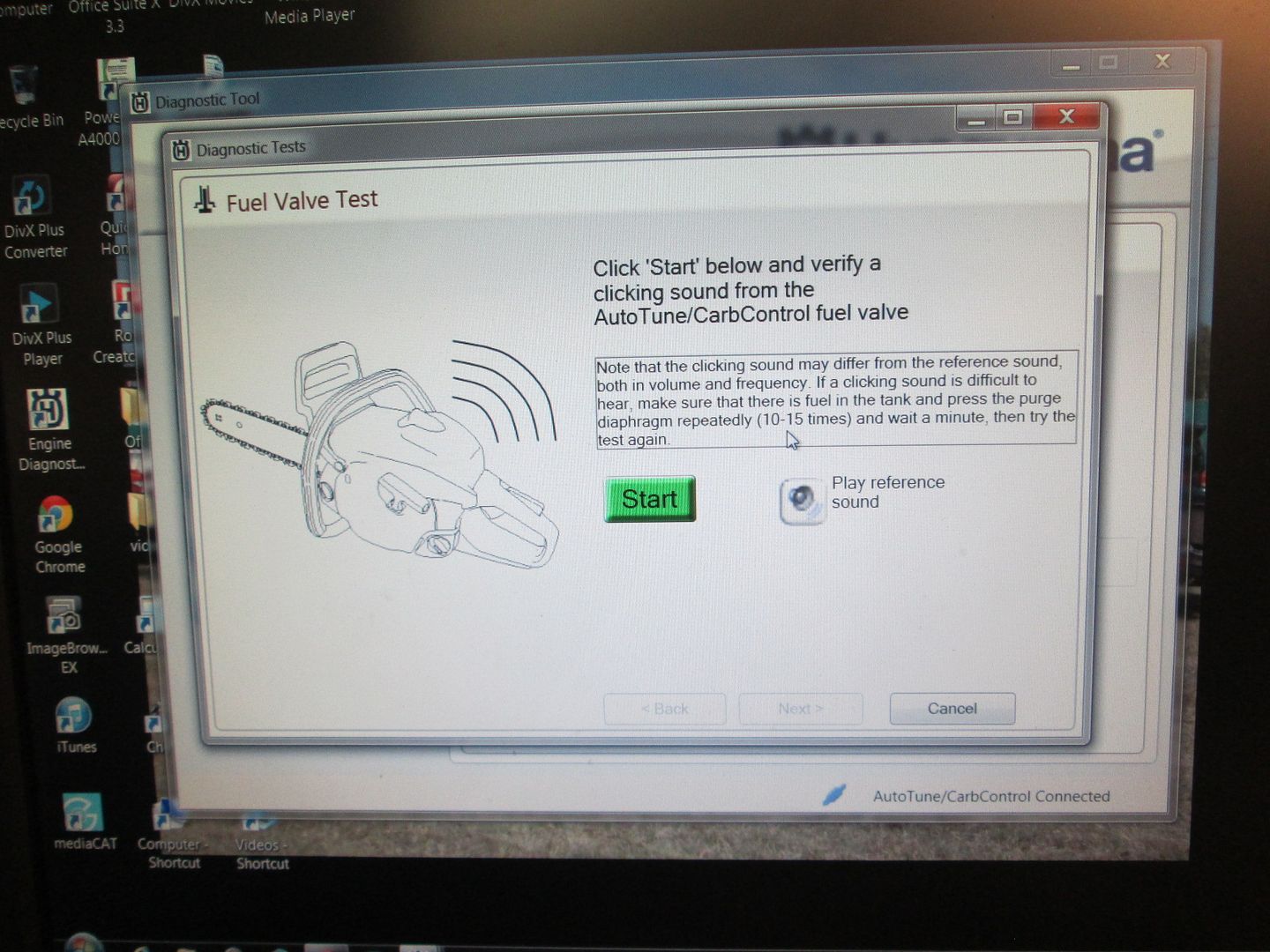

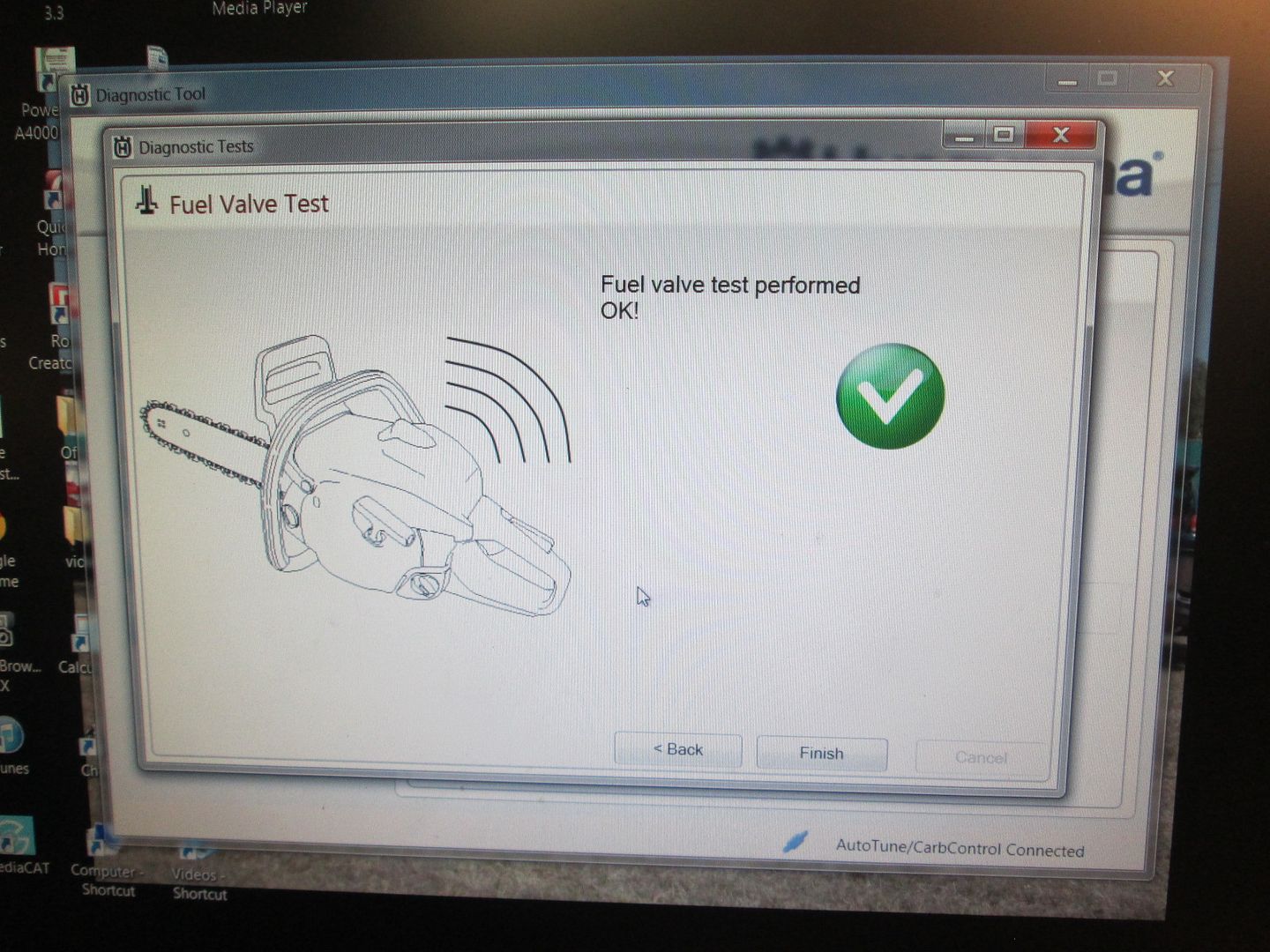

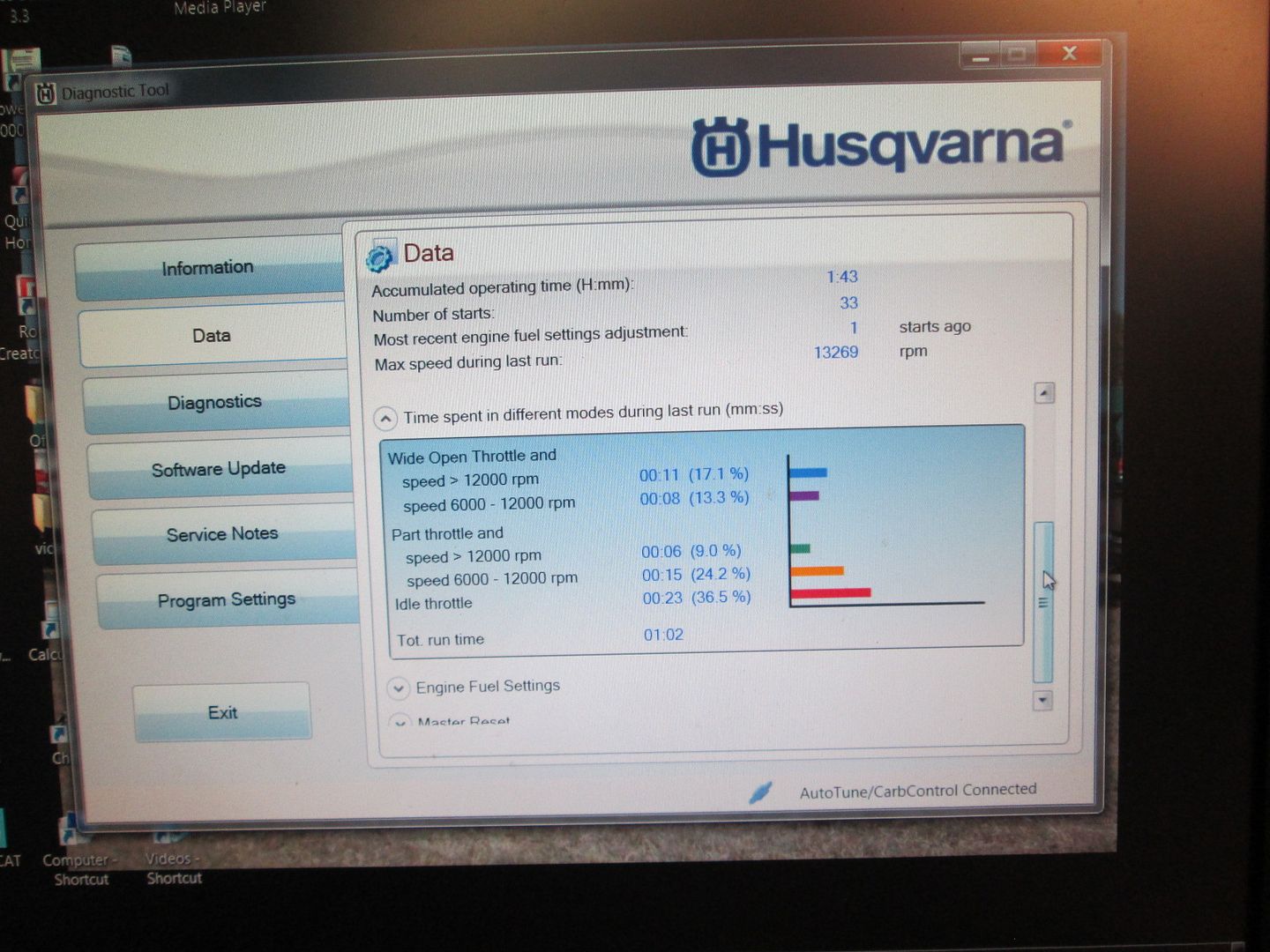

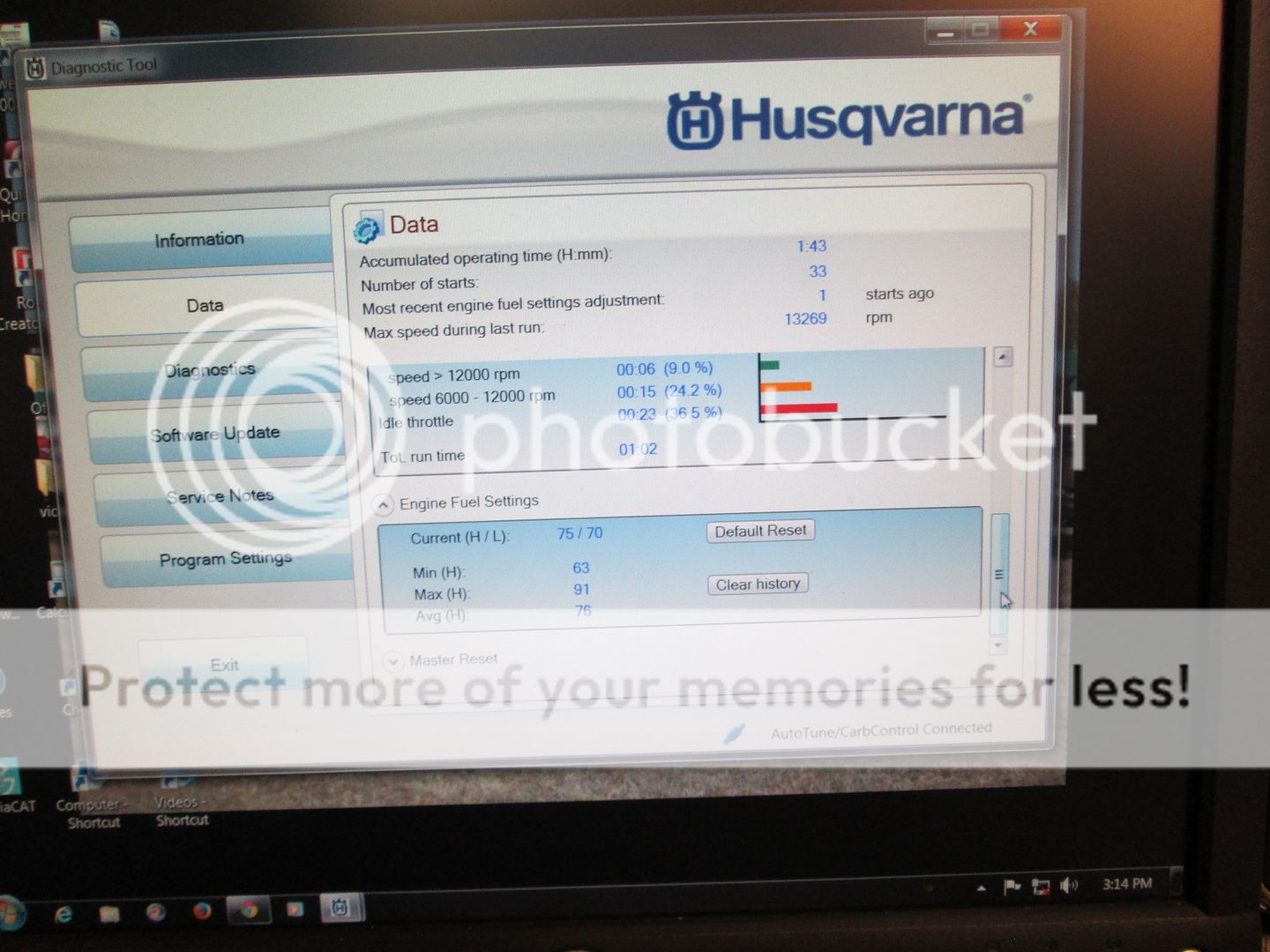

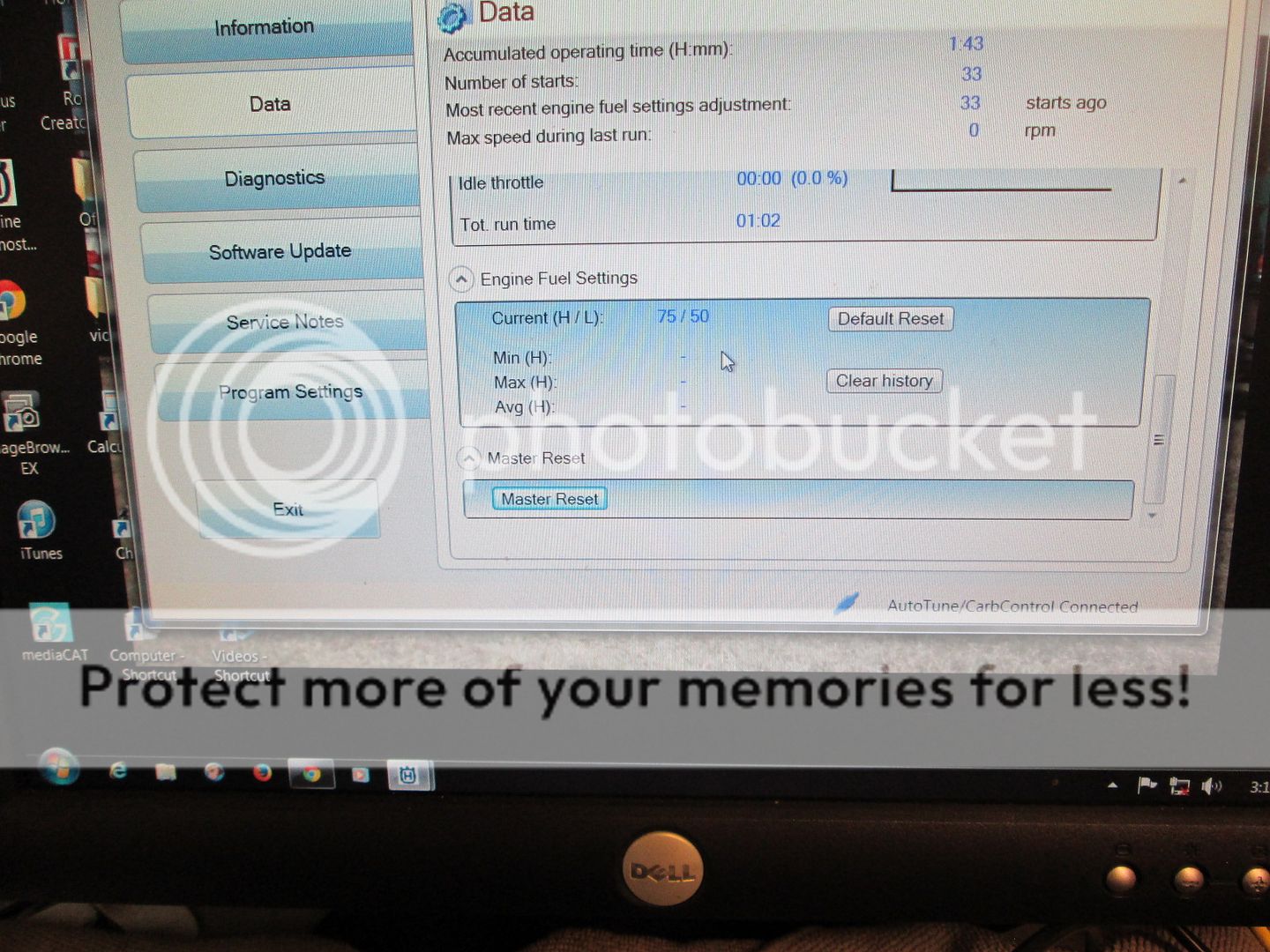

laptops replacing muh orange screwdriver ?

Inevitably

laptops replacing muh orange screwdriver ?

laptops replacing muh orange screwdriver ?

Inevitably

laptops replacing muh orange screwdriver ?

Dude you got a dell

Maybe some startup might come up with an aftermarket reader that would work on both autotune and mtronic. Niche product now, but with most likely most small engines headed this way..hmmm

Interesting that one out of three had an air leak and those are all fairly new saws. Shouldn't be any air leaks. Wonder how many other 550s are out there with running issues because of that. Unless that 1/3rd random sample is way skewed by some odd chaotic random chance event, that seems high to me. And with the autotune compensating, there could be a lot of guys running slightly defective saws at reduced power because of it, and not even know they have an air leak issue, if this is common.

Let alone dealers who still don't have the gear and training to analyse the saws, let alone individual owners.

I think husky is dropping the cheap-out ball. They should provide a data cable and DVD with every saw. IMO, the owner has a right to know what the heck is going on with their saw, to at least some normal reasonable extent, without having to schlep it to a dealer or to someone who afforded the $$$ to purchase their IP precious.

Or something, heck, anyone can go into wallyworld and score an OBD reader cheap for their ride and at least get some clue as an owner about repairs/error codes, etc.

Maybe some startup might come up with an aftermarket reader that would work on both autotune and mtronic. Niche product now, but with most likely most small engines headed this way..hmmm

1/3rd of all 550xp's shipped have air leaks because that's how many did at Randy's little shop of horrors......

Everything looks like it is easy to get to on the 550....wide open, not many tight spots...?

Everything looks like it is easy to get to on the 550....wide open, not many tight spots...?

Quick question about your tools...I just ordered a cc Specialties TX Motor(One direction) and now i'm second guessing myself...Should i call them and tell them i want the SR motor(Reversible)? I know i can put the bits in ether side of the 182, but is it a PITA to switch from one side to the other?

Assuming a reasonably clean saw to start with.

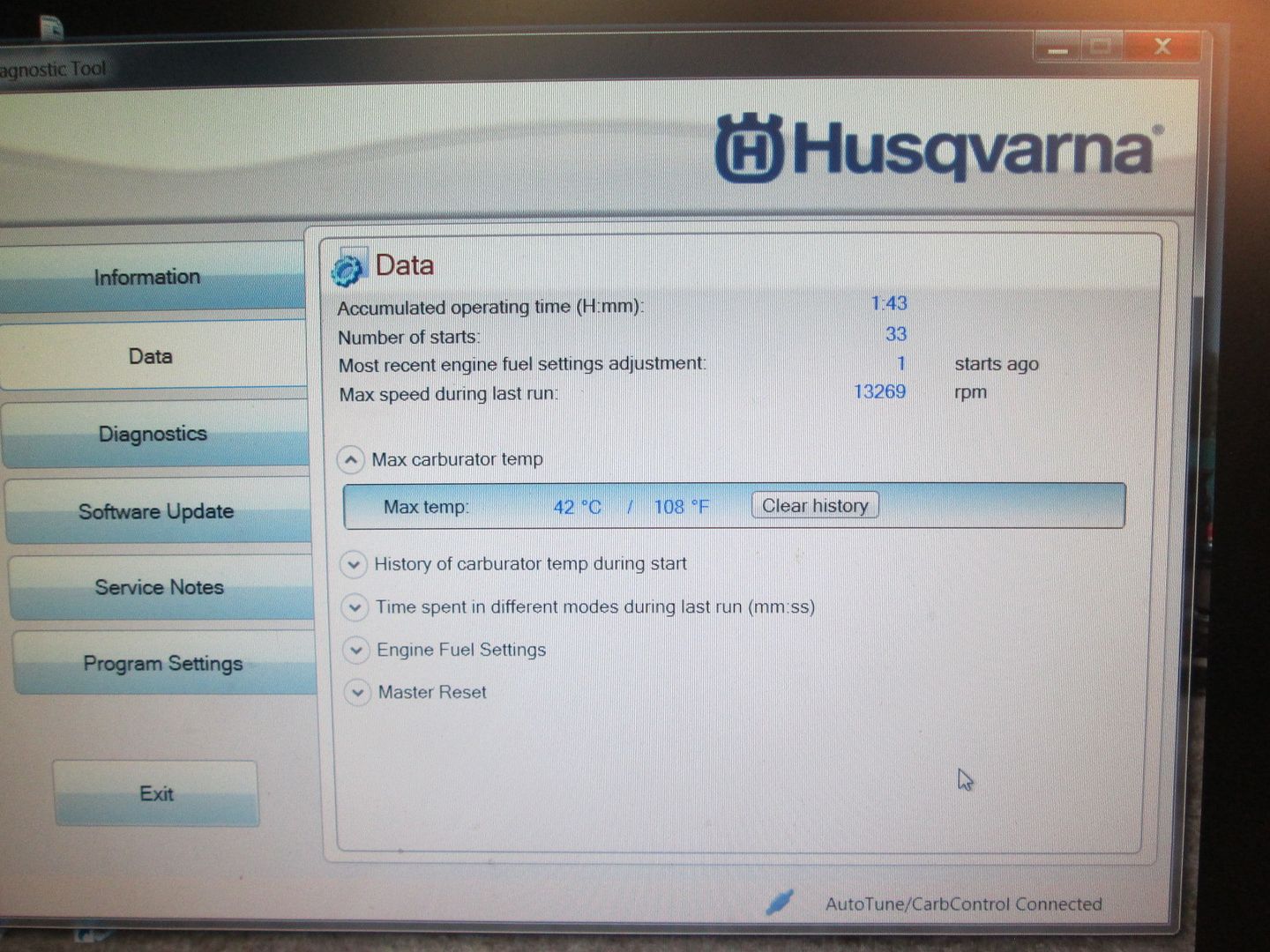

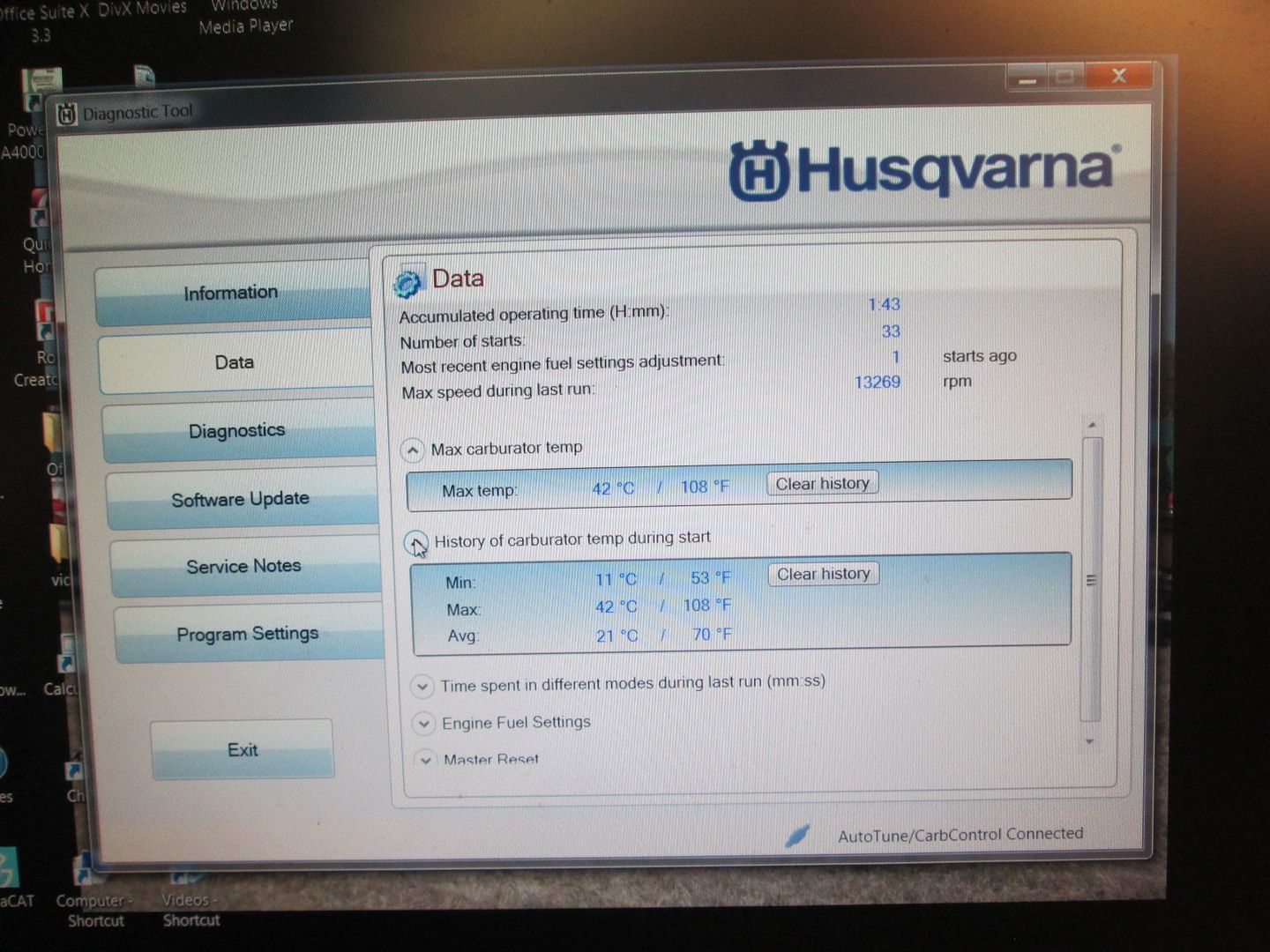

*Roughly* how long does it take to hook up and read the data

once you've become familiar with the procedure?

I'm hoping to see someone make a simple "T" into the data line

and record some running data.

stick the laptop in a backpack and go work 'er a bit.

I've expressed my concerns/dislikes elsewhere over the start counter

lack of a user reset kit..yada yada...

But as long as it's there, then let's see how we can play with it, right??

It's made to read data while the saw is not running.

ah, just a detail my Good Man.

and the code jockeys/hardware hackers have Officially been challenged !!

(that pesky market segment size thing again)

Buss pirate or somesuch data sniffer anyone? ( i'm not up to date on the tools)

anyone else here read Hackaday com ?

1/3rd of all 550xp's shipped have air leaks because that's how many did at Randy's little shop of horrors......

tl;dr

Enter your email address to join: