Recently I had an 026 in for repairs, owner said it would run but not too well. I checked it out and it needed a piston/cylinder plus a few screws, etc. Upon checking further I noticed that the previous owner broke the fuel line and attempted to glue it back together. I found half the fuel line lying in the bottom of the tank. I imagine the lean condition that caused probably burned out the piston/cylinder.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

026 won’t run

- Thread starter axe2fall

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

axe2fall

Hound runner

No. I have my farm to run. Discing in lime but 4 bearings went. A contracting business where the phone never stops and a rental property endeavor with a fridge acting up in one and water heater in another. A kennel full of hounds and a litter of puppies. A greenhouse full of fresh sprouts.. A bunch of kids I watched grow up are getting married so social obligations. I assure you i have not been sitting around.The suggestion that you pressure test the rings, & crank seals, and vac test the jug, for induction leaks? Those are also basic small engine mechanics, Small Engine Class 2.0. Those tests should have already been performed, with proper equip't.

If this is a sit on your hands for months post.............get off your ass.

gonna check the timing and rubber. Then find all of my block off plates and miti vac... My grandson wanted to come home with us last night so he is my priority today.

Saw runs well

Who is "they"? "They" is wrong!as they say, 99% of fuel carb problems are electrical

Yup, I see way more fuel problems than electrical.Who is "they"? "They" is wrong!

I have an 026 right now that will high idle but not run correctly or idle properly.

I can have it on high idle and squirt starter fluid behind the carb box and kill it dead as a hammer.

Been too busy to chase it down. Maybe I'll get time tomorrow.

I can have it on high idle and squirt starter fluid behind the carb box and kill it dead as a hammer.

Been too busy to chase it down. Maybe I'll get time tomorrow.

I would definitely pressure test that one..I have an 026 right now that will high idle but not run correctly or idle properly.

I can have it on high idle and squirt starter fluid behind the carb box and kill it dead as a hammer.

Been too busy to chase it down. Maybe I'll get time tomorrow.

I would definitely pressure test that one..

I never pressure test anything. If you are too dumb to figure out if something has a leak without putting a gauge on it, good luck in the contest.

I'll have it fixed and out the door while you are scratching your ass.

Good luck in the future, you'll need it..I never pressure test anything. If you are too dumb to figure out if something has a leak without putting a gauge on it, good luck in the contest.

I'll have it fixed and out the door while you are scratching your ass.

I suspect I have been doing this longer than you have.Good luck in the future, you'll need it..

To me, vacuum and pressure testing are my guarantee to me that the bottom end is not causing problems. You still have to look at the mechanical visually.

Guess it is like the old Homelite mechanic that told me it was a waste of time. I then straightened out 4 Homelites in a row with intake leaks and seals he had worked on.

Stihl recommends it and supplies all adapters. Waste of time? Not for me.

Guess it is like the old Homelite mechanic that told me it was a waste of time. I then straightened out 4 Homelites in a row with intake leaks and seals he had worked on.

Stihl recommends it and supplies all adapters. Waste of time? Not for me.

guysmiley

ArboristSite Lurker

it is a saying from the automotive mechanical world... maybe it is not 99%, maybe the verbage is "most" or whatever it is but the idea is that many people blame the carburetor when in fact it is an ignition fault etc.Who is "they"? "They" is wrong!

Needless to say all diagnostic work should be done including electrical even if it is suspected fueling issue whether it be a v8or a 2 stroke.

To me, vacuum and pressure testing are my guarantee to me that the bottom end is not causing problems. You still have to look at the mechanical visually.

Guess it is like the old Homelite mechanic that told me it was a waste of time. I then straightened out 4 Homelites in a row with intake leaks and seals he had worked on.

Stihl recommends it and supplies all adapters. Waste of time? Not for me.

My point is, if I spray starter fluid behind the carb box on the intake boot and impulse line and it kills the saw I know it has an air leak.

And, if I didn't already know it had an air leak I wouldn't have been trying to chase it down to start with.

I'm 80 years old and have been messing with saws since I was in high school..I suspect I have been doing this longer than you have.

Well I'd say he's been given every suggestion there is for a fix at this point.

Why not just let the fella get back with us in his own time and not belittle him about it.

After all, he merely asked for our help. We've all been there gents.

Also related to the one post about impulse line and boot, fuel lines and filter, definitely check all fuel related rubber parts.

On my 1994 one owner, ME, 026, By the time it began running poorly or being hard to start, then run poorly, i turned out that my fuel lines were a gooey and sticky mess to the touch and definitely restricted fuel flow. The carb was also likely gummed up but I did not overhaul it. I replaced the impulse, fuel lines and filter. I was able to then get it running by using a carb off a known good running 026. When all seemed good, I bought a new carb to install on my original 1994 saw and put the donor carb back onto the saw it came from.

Well, glad you are still kicking around. If you can get a saw to run you can tell whether or not it has an air leak by the way it acts. And, unless the rings are seized you can usually make them run to some extent. If the piston is scored and rings seized you can inspect the intake and impulse easy enough when you have the cylinder off. Once you have it rebuilt if it still acts like it has a leak really doesn't leave much but cranks seals. And, if you did pressure test it beforehand it would not have told you where it was leaking.I'm 80 years old and have been messing with saws since I was in high school..

That's what the starter fluid is for.

I often pressure test fuel lines before taking them out of the saw.

etbrown4

ArboristSite Operative

Did the saw ever get repaired? Its been 5 months.

You said it would run a few secs on gas introduced through the plug hole, but not on spray through the carb. While there could be an air leak, I'd replace the carb for $20-25 and expect that to fix it. With those symptoms, you have a good chance of success and little to lose!

You said it would run a few secs on gas introduced through the plug hole, but not on spray through the carb. While there could be an air leak, I'd replace the carb for $20-25 and expect that to fix it. With those symptoms, you have a good chance of success and little to lose!

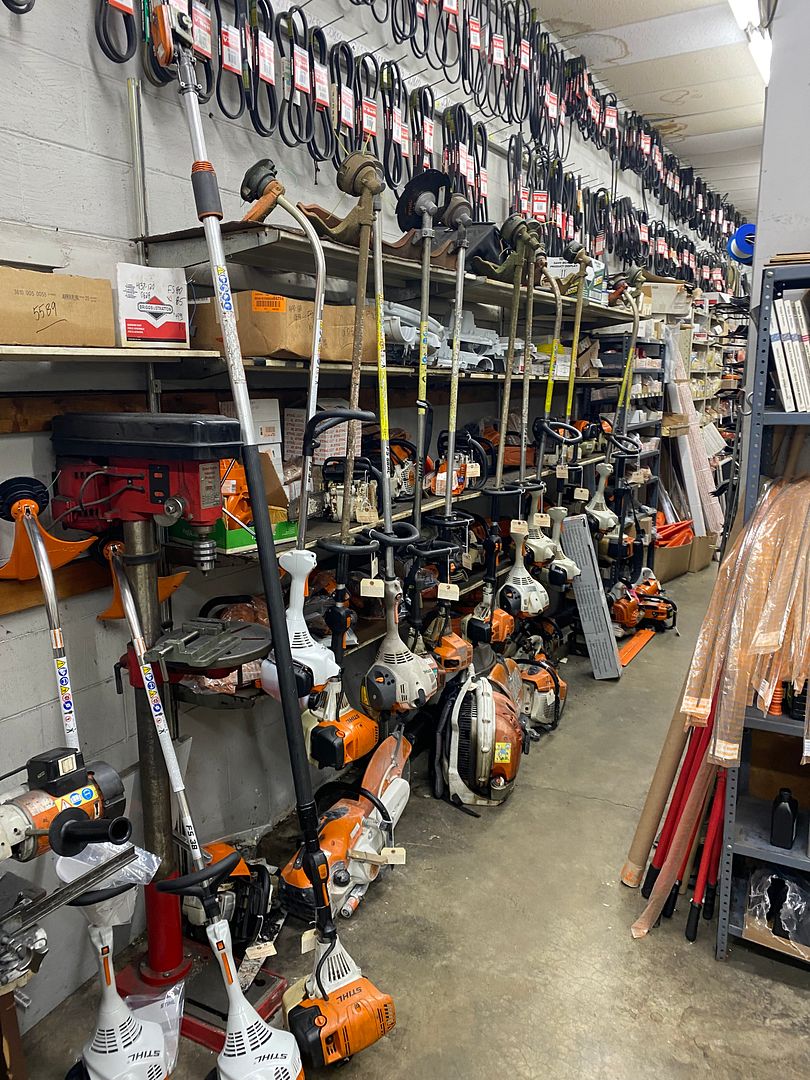

This is what I am looking at most every day when I come in. I'm sure I repaired it. But, I don't remember it.

Apologize if you were addressing the OP .