The only thing I'm still confused on is the math to convert to (theoretical) RPM's. How are you getting RPM from Hz ... which frequency? Which peak? :help:

A power spectrum is audio power level plotted vs. frequency instead of power level plotted vs time (what you normally see as an audio track). This spectrum is generated by a mathematical manipulation called a Fourier transform. Assuming the chainsaw is generating the loudest sound in the recording, then the peak with the most power (highest on the dB scale) will be due to the saw. The lowest peak will be the fundamental frequency and it's frequency is directly proportional (by a factor of 60) to the RPM of saw. Remember the fuel/air mixture explodes once per revolution, so revs/min = 60 * revs/sec (in Hz). So if a the biggest amplitude and lowest frequency peak is 100 Hz, that is probably the fundamental (check the harmonics). So, RPM = 100*60 = 6000.

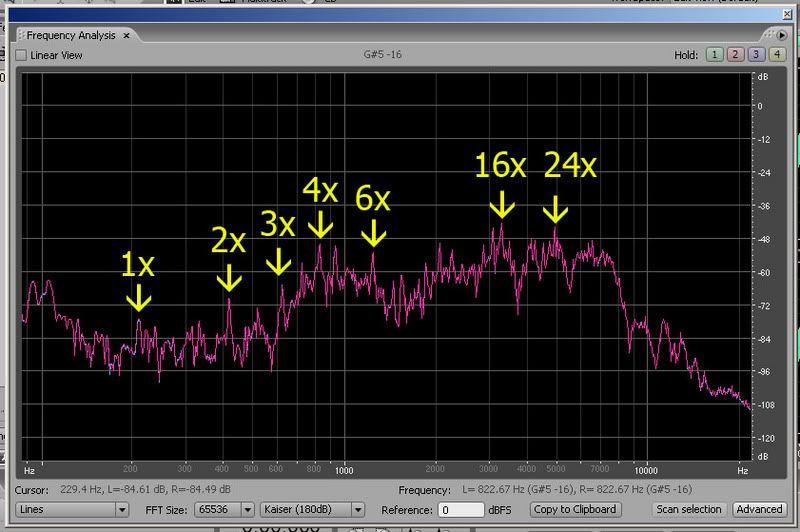

"Harmonics" are integer multiples of the fundamental frequency (because of natural resonance phenomenon). Thus, if a fundamental frequency = 100 Hz, you would expect to see a series of peaks at 200, 300, 400, 500, etc. How high in frequency the harmonics go, depends on the initial sampling rate, bandwidth of the recording, the saw itself, and the environment. The harmonic peaks are useful because they can aid in an accurate determination of the fundamental frequency. So, my attached image above (post #20), you can see that the 3 highest power peaks are at 200, 400, and 600 Hz. The lowest is the fundamental and the others are harmonics. So, multiply 200 bangs (revs)/sec by 60 sec/min and you get 12,000 revs/min.

In my software, I can watch the power spectrum as the audio track is being played and can pretty easily look for highest and lowest RPMs acheived. A nice feature, but not really necessary. When you do this kind of analysis, you need to make sure that you select only the short time window (usually about 1 second) that you are interested in, so you get the cleanest power spectrum. If you create the power spectrum for the whole audio track at once, you will have a frequency mess and it'll be hard to discern what's going on. This is very important, especially because the RPM varies with time due to bogging, throttle blipping, etc. You must only analyze a time period where the RPMs sound pretty constant.

This is way more than most need/want to know, but since you asked... After I see a few more videos with tach information and keep seeing agreement, I'll probably look for some simple freeware that could allow others to easily do this, if they are so inclined.