sperho

ArboristSite Operative

I took what was said earlier and did some playing around...I used a 1 second snippet from that company's video about chaps, with the saw taching out at 12200.

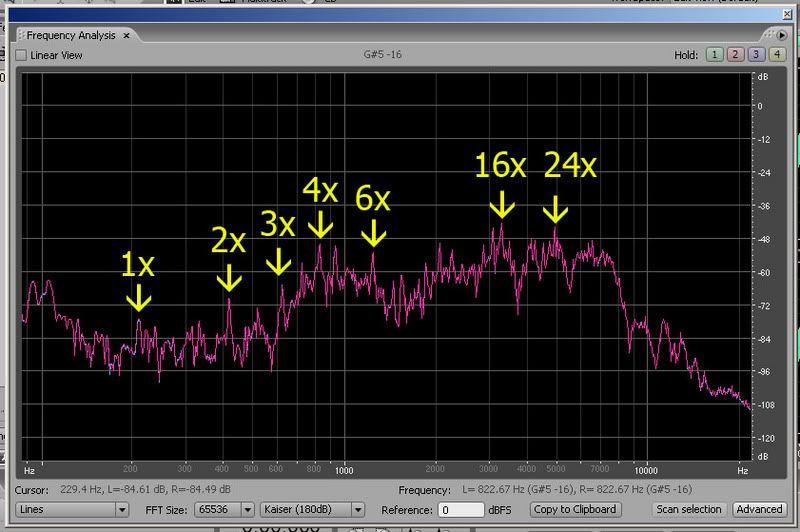

Running the frequency analysis in Adobe Audition, I got a familiar graph...note the peaks, indicated by the arrows:

The peaks are at the following Hz, which calculate into RPMs as mentioned earlier, correcting for the various harmonic factors:

= 24x > 12445 RPM

- 208 hZ = 1x > 12480 RPM

- 417 hZ = 2x > 12510 RPM (417*60/2)

- 624 hz = 3x > 12480 RPM

- 832 hZ = 4x > 12480 RPM

- 1246 hZ = 6x > 12460 RPM

- 3321 hZ = 16x > 12453 RPM

- 4978

Using the harmonics helps verify the readings, and they all average out to 12471 RPM, which is pretty close to the tach reading. The slight discrepancy MIGHT be from the video compression causing a slight increase in frequency...either way, it's pretty close.

Thoughts?

Well done. We agree to within about 4% and you're 2% away from BobL. You might play around with the FFT settings and windowing functions to give you better looking power spectrums to find the fundamental more easily. You can see what my setting were in my graphic attached about half way down the thread.

Last edited:

Seems like a lot more people here "waste" time trying to eek out HP out of their saw for no practical reason; at least I've saved some cash with my waste of time.

Seems like a lot more people here "waste" time trying to eek out HP out of their saw for no practical reason; at least I've saved some cash with my waste of time.