Woodplayer

ArboristSite Member

Hi Guys

I've been lurking on this "great" forum for a few months and hadn't posted yet since I was able to find the answers to all my questions. (except one).

(BTW I purchased my latest saw Dolmar 5100s due to the feedback on this forum. Man, after 8 tanks of gas that thing rocks!!):rockn:

On to my problem. I have a 15 yr old McCulloch PM325 (small 35 cc saw) which has had intermittent problems for the past few years.

Seems to have trouble idling, and after shutting off it usually won't start for 1/2hr.(flooded) Back in the summer, I assumed it was

the fuel tank pressure problem, since the fuel tank is mounted overtop of the engine and I did notice pressure when removing the fuel cap.

However I used it again last week (below freezing) and even before it was warmed up much the idling problem was there and it wouldn't start,

immediately after shut down. (no pressure in the tank) I have even disconnected and plugged the fuel lines to/from the primer bulb.

The saw starts and runs great in partial and WOT (high speed screw about 1 1/4, low speed 1 1/8)

It appears that the carb runs very rich on idle. I've noticed fuel coming out in the venturi from what appears to be the main nozzle during idle

as well when the saw is shut off. On one occasion by continually blurping the throttle slightly at a fast idle, I adjusted the low speed

screw all the way in (lightly seated) and it still ran rich. Only after turning the high speed screw in about 3/4 turn, did the fuel appear to stop

flowing from the main nozzle (fast idle chain slightly moving)

I took the zama carb apart, blew out all the passages, nozzles, inlets etc. (which looked very clean) and even tried to very

slighty decrease the metering lever height from it's recommended height of 0 to -0.012" from the carb body. This didn't make any

difference.

I figured perhaps the metering diaphragm or pump diaphragm were too stiff (Seemed alright to me), so I picked up a carb kit.

Both these diaphragms as well as gaskets, metering lever, valve inlet needle, pin, metering lever spring, strainer were carefully replaced

but the saw still has the exact same problem (flooding, excessive fuel at idle)

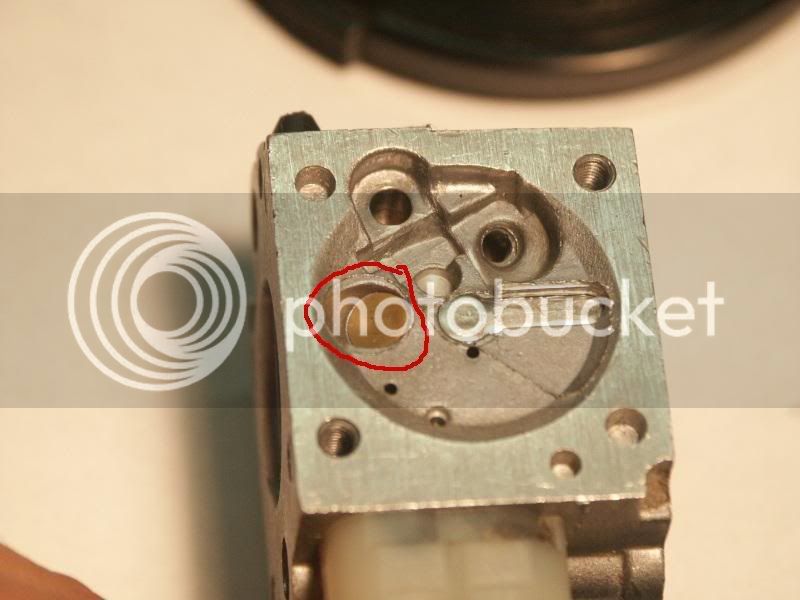

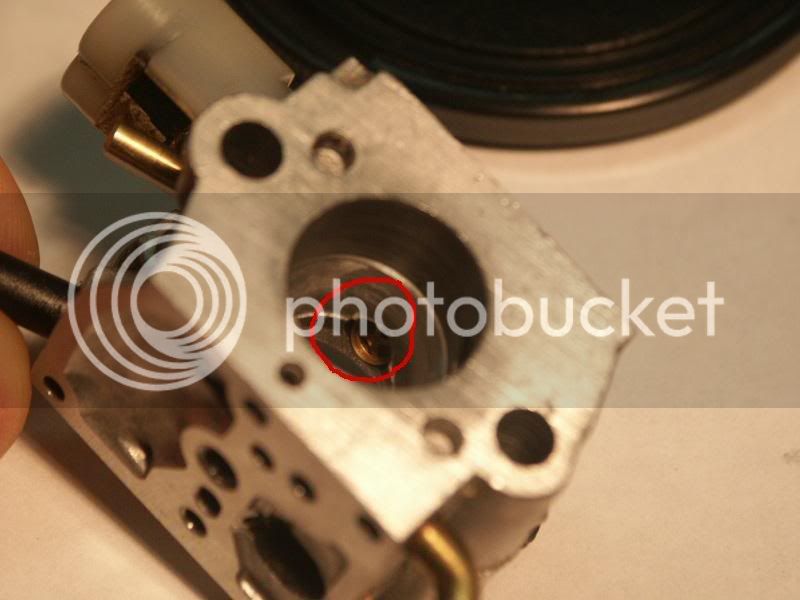

The only thing that I didn't remove and inspect was under the welch plug. My understanding is that all that could really go wrong in there

is the check valve for the idle chamber or main nozzle could be malfunctioning, but those check valves allow fuel to flow out into

the venturi but don't allow air back into the carb. My problem appears to be related to the main nozzle during idle allowing fuel to flow

into the venturi. Is not the fuel flow to from the main nozzle only during low pressure (vacuum), not during idle or when the engine is off? :bang:

Hopefully what I have posted is understandable, if anyone has any thoughts or suggestions I would REALLY appreciate them!!

I may try removing the welch plug and hope I don't ruin anything underneath.

Thanks Guys!!

I've been lurking on this "great" forum for a few months and hadn't posted yet since I was able to find the answers to all my questions. (except one).

(BTW I purchased my latest saw Dolmar 5100s due to the feedback on this forum. Man, after 8 tanks of gas that thing rocks!!):rockn:

On to my problem. I have a 15 yr old McCulloch PM325 (small 35 cc saw) which has had intermittent problems for the past few years.

Seems to have trouble idling, and after shutting off it usually won't start for 1/2hr.(flooded) Back in the summer, I assumed it was

the fuel tank pressure problem, since the fuel tank is mounted overtop of the engine and I did notice pressure when removing the fuel cap.

However I used it again last week (below freezing) and even before it was warmed up much the idling problem was there and it wouldn't start,

immediately after shut down. (no pressure in the tank) I have even disconnected and plugged the fuel lines to/from the primer bulb.

The saw starts and runs great in partial and WOT (high speed screw about 1 1/4, low speed 1 1/8)

It appears that the carb runs very rich on idle. I've noticed fuel coming out in the venturi from what appears to be the main nozzle during idle

as well when the saw is shut off. On one occasion by continually blurping the throttle slightly at a fast idle, I adjusted the low speed

screw all the way in (lightly seated) and it still ran rich. Only after turning the high speed screw in about 3/4 turn, did the fuel appear to stop

flowing from the main nozzle (fast idle chain slightly moving)

I took the zama carb apart, blew out all the passages, nozzles, inlets etc. (which looked very clean) and even tried to very

slighty decrease the metering lever height from it's recommended height of 0 to -0.012" from the carb body. This didn't make any

difference.

I figured perhaps the metering diaphragm or pump diaphragm were too stiff (Seemed alright to me), so I picked up a carb kit.

Both these diaphragms as well as gaskets, metering lever, valve inlet needle, pin, metering lever spring, strainer were carefully replaced

but the saw still has the exact same problem (flooding, excessive fuel at idle)

The only thing that I didn't remove and inspect was under the welch plug. My understanding is that all that could really go wrong in there

is the check valve for the idle chamber or main nozzle could be malfunctioning, but those check valves allow fuel to flow out into

the venturi but don't allow air back into the carb. My problem appears to be related to the main nozzle during idle allowing fuel to flow

into the venturi. Is not the fuel flow to from the main nozzle only during low pressure (vacuum), not during idle or when the engine is off? :bang:

Hopefully what I have posted is understandable, if anyone has any thoughts or suggestions I would REALLY appreciate them!!

I may try removing the welch plug and hope I don't ruin anything underneath.

Thanks Guys!!