chadihman

Addicted to ArboristSite

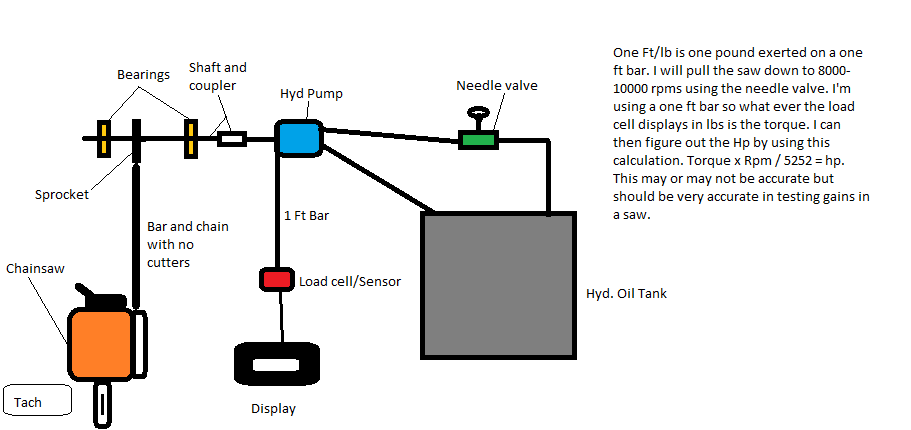

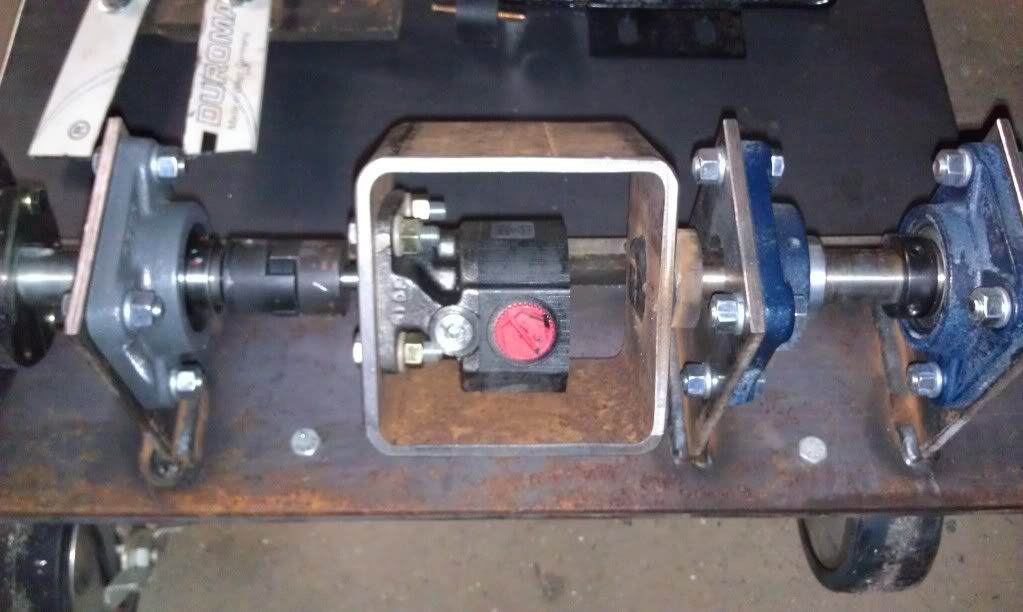

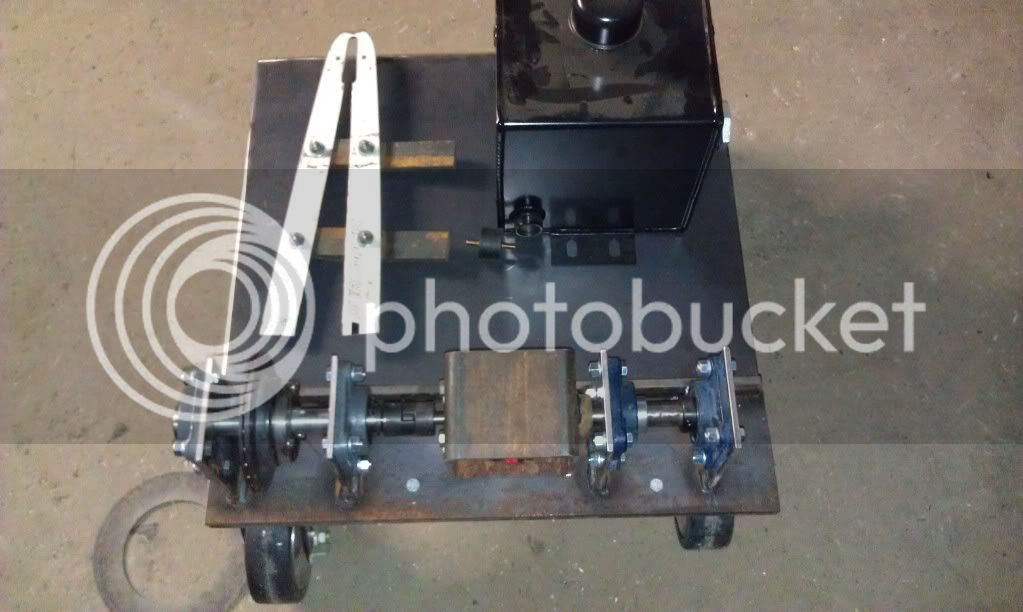

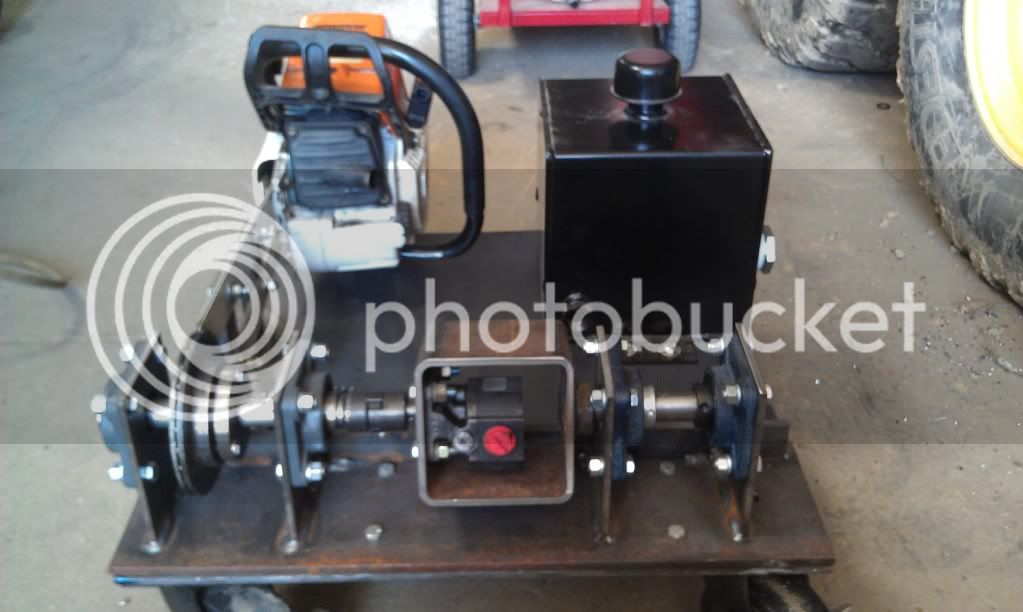

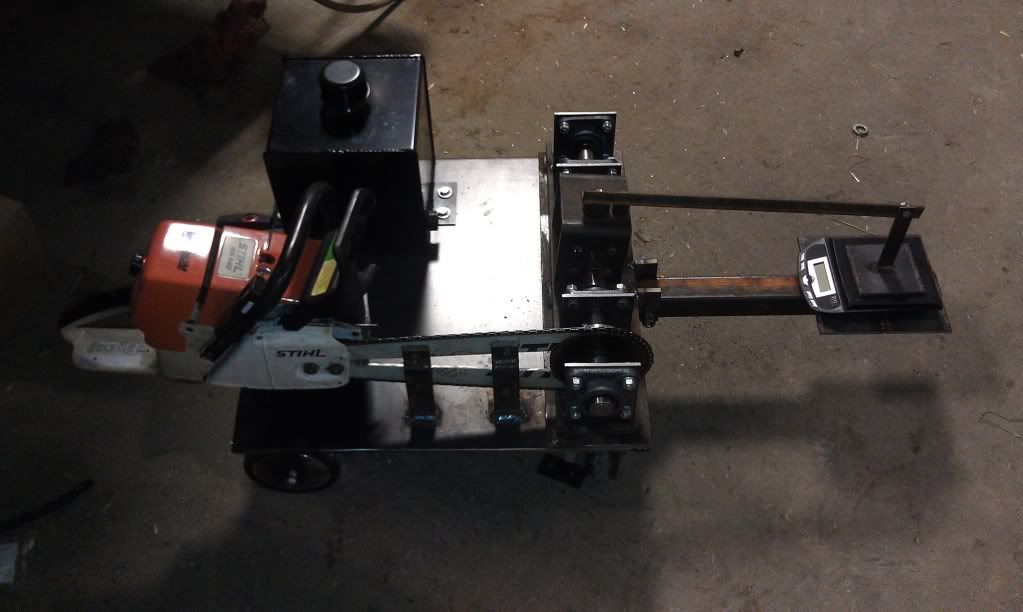

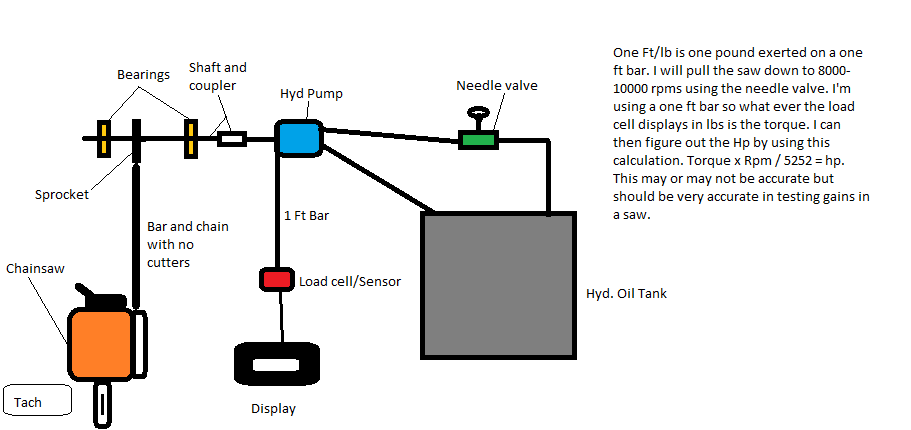

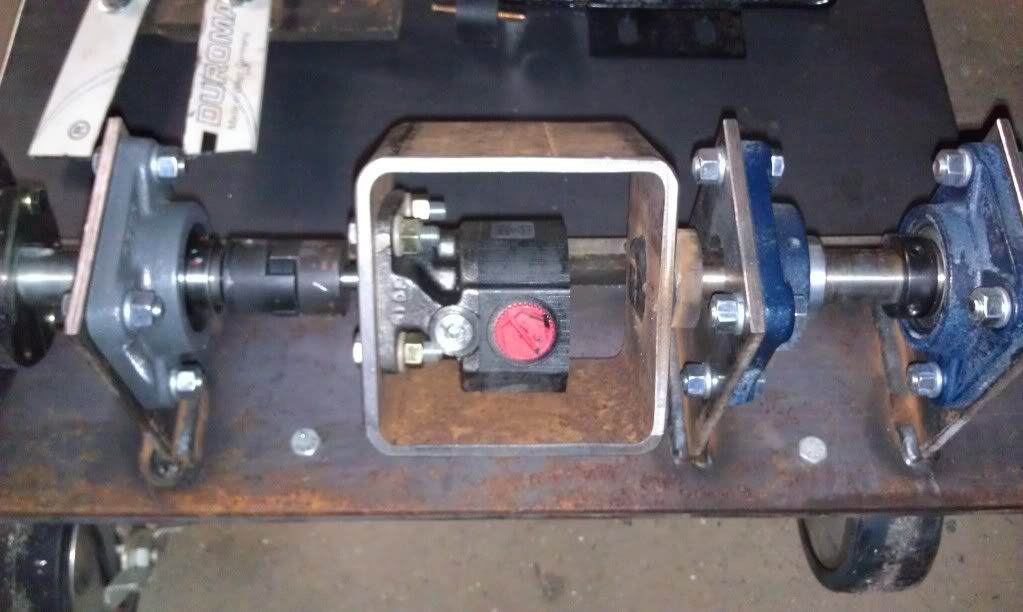

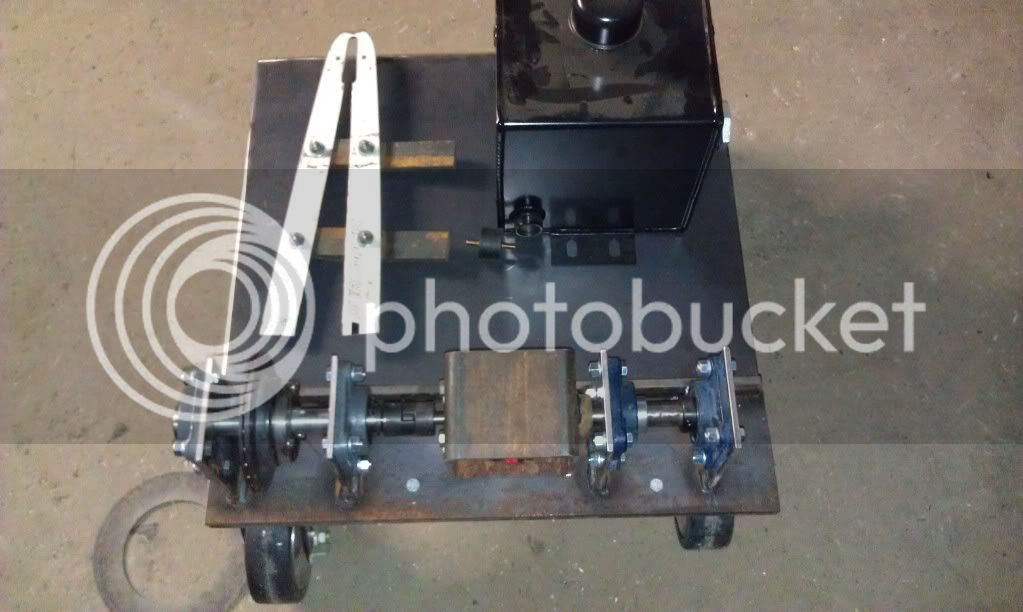

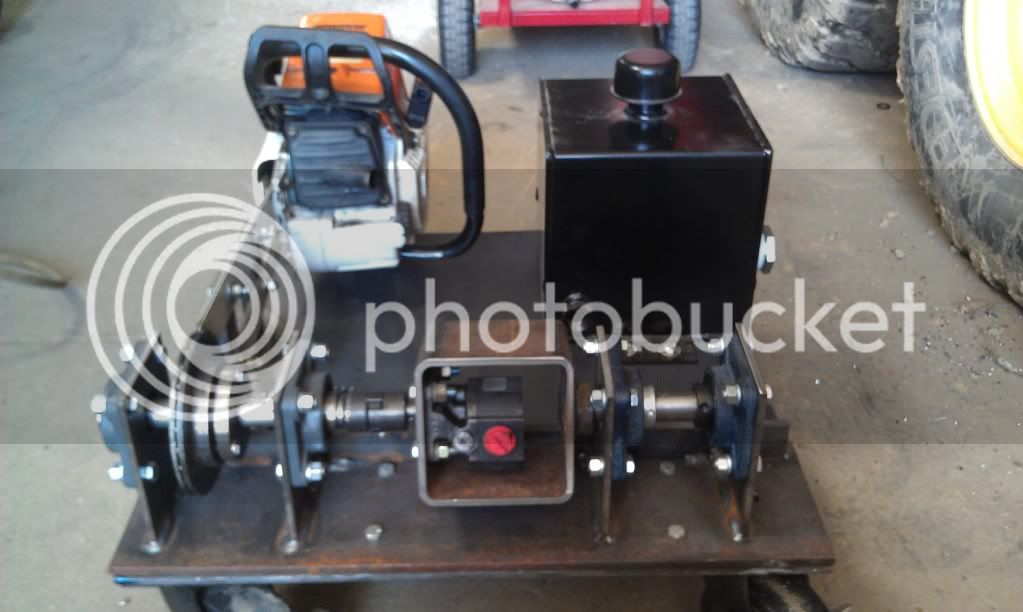

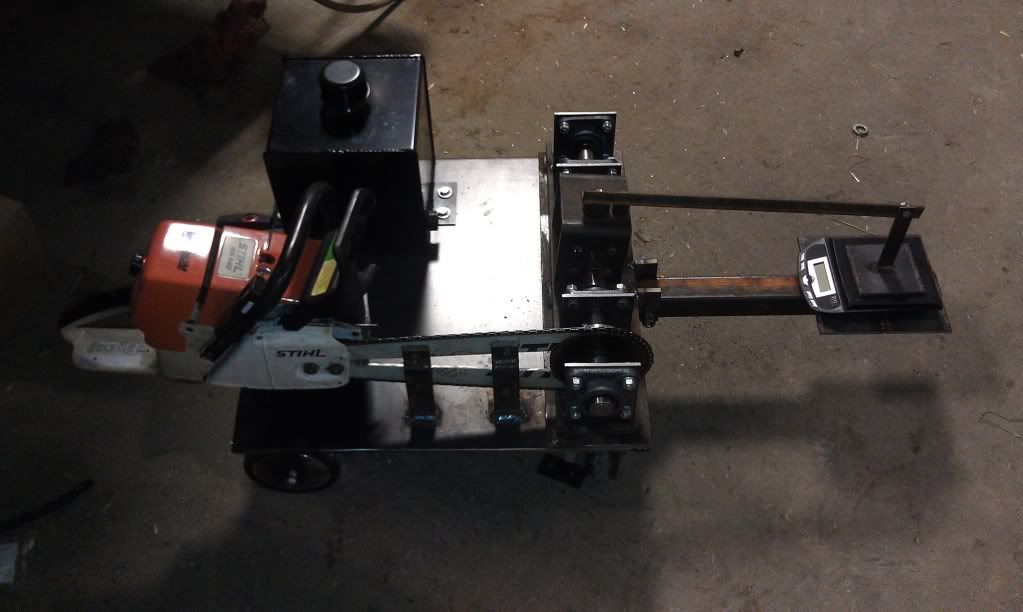

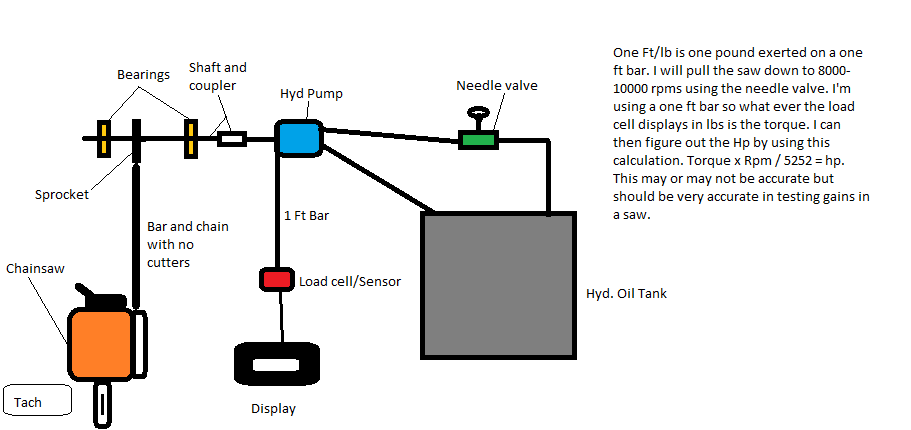

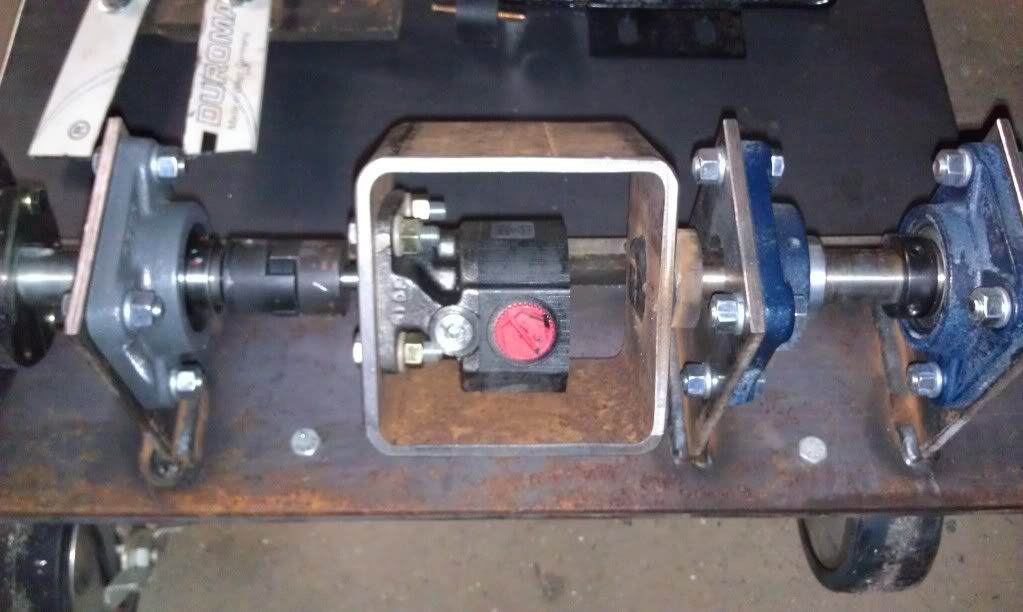

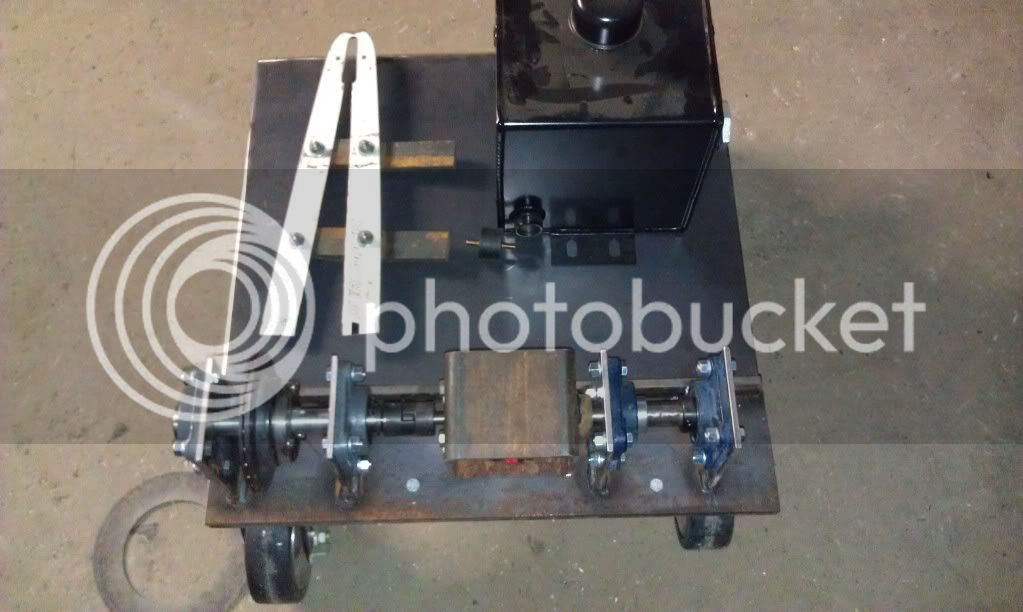

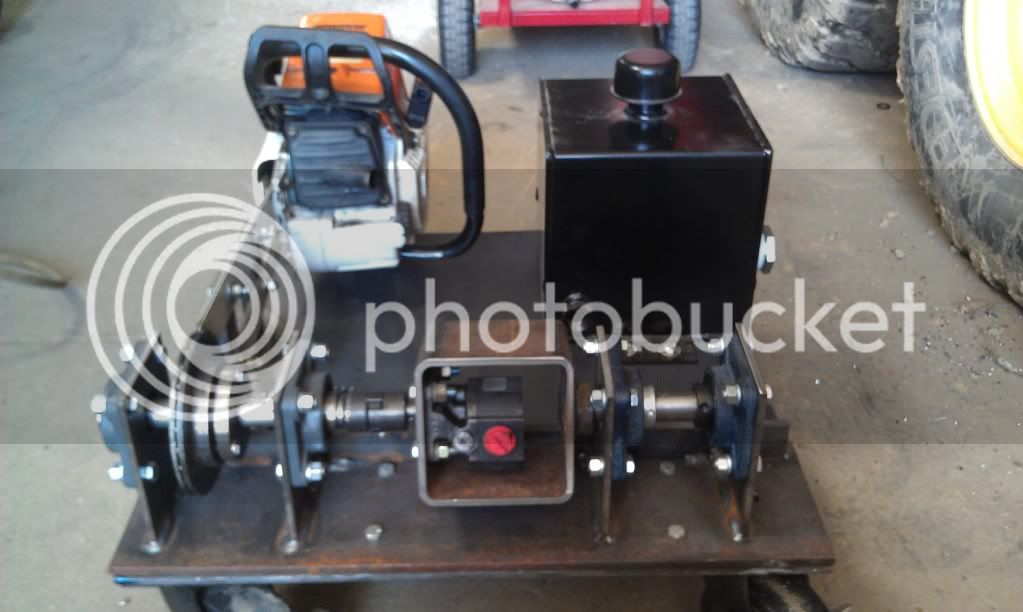

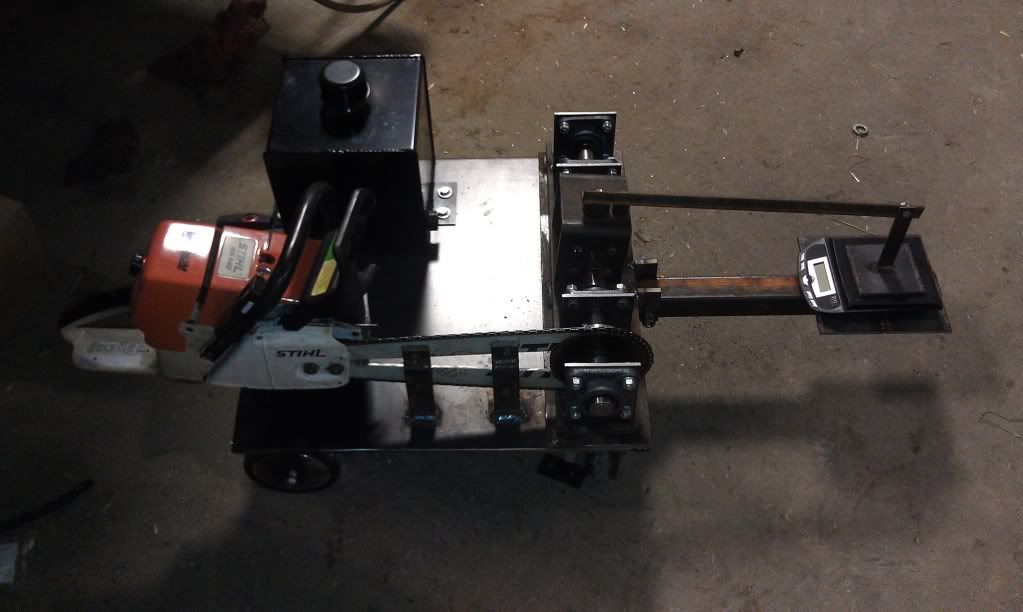

Got the dyno done for the most part. I have lots of pictures of the build and a video of a MS 460 begging for mercy.

Wheres the video and does it show read outs etc.

Wheres the video and does it show read outs etc.Very cool, did you get a HP reading close to stock?

Fantastic job Chad!

There is a German testing site that has actual dyno numbers on stock saws (don't remember the site off the top of my head) Sawtroll?

This would help you better corilate your test numbers because the advertised hp numbers on saws are not real accurate as you probably know.

May I suggest an experiment/test. How about doing engine mods step by step, one mod then test, then another. Such as muffler mod - test, then port the exhaust only - test, tighten up the squish clearance - test, etc. etc.

May I suggest an experiment/test. How about doing engine mods step by step, one mod then test, then another. Such as muffler mod - test, then port the exhaust only - test, tighten up the squish clearance - test, etc. etc.

Enter your email address to join: