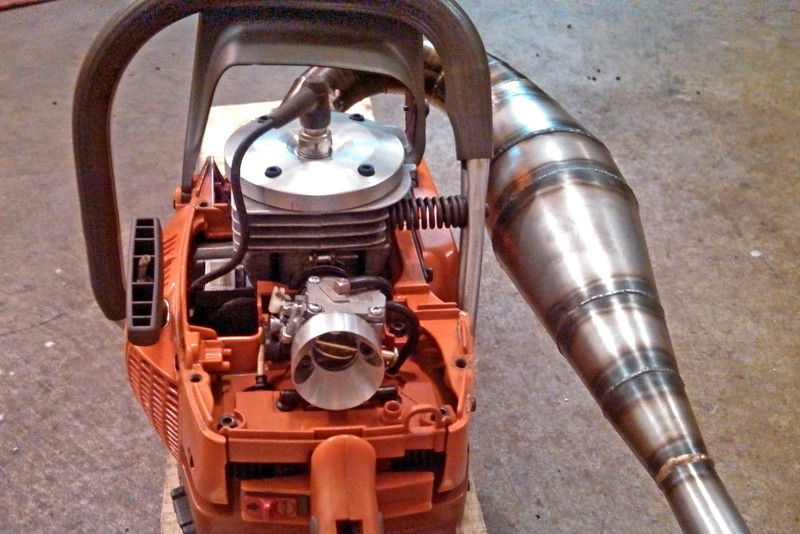

Tons of cleanup, alignment, finish welding, and adding mounts left to do, but I managed to find a couple hours to get everything mocked up. The pipe is just hanging off the stock bolts in the photos, so the alignment isn't exact.

I'll be capping the end and adding a center dump stinger, which seems like the best route from both a noise and compactness standpoint. But that will have to wait until another day (after the holidays in all likelihood).

I'll be capping the end and adding a center dump stinger, which seems like the best route from both a noise and compactness standpoint. But that will have to wait until another day (after the holidays in all likelihood).