You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Granberg vs. Holzforma 36" Alaskan Mill (A Comparison)

- Thread starter JohnWayne

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There's nothing that expert about it .

Here we go, off the shelf 72" mill rails for your Granberg

http://www.baileysonline.com/Forest...Granberg-72-Alaskan-Mill-Rail-Set-G781-72.axd

I see baileys also has an 87" woodland double ended bar for sale.

Here we go, off the shelf 72" mill rails for your Granberg

http://www.baileysonline.com/Forest...Granberg-72-Alaskan-Mill-Rail-Set-G781-72.axd

I see baileys also has an 87" woodland double ended bar for sale.

Dad was a tree faller in the Italian alps before migrating to Australia in the early 1950's. He worked in a sawmill for a year before he and his workmate (Charlie) managed to get a contract falling 200ft al karri trees. The started out with Axes and cross cut saws. The had to cut steps an insert boards as steps to get up to a thinner part of the tree like this

Then they would cut the scarf with axes. some of trees were so massive that they had to crawl inside the scarf to complete the cut. Charlie was smaller than dad so he dis that. The the cross cut from behind and jump and run for your life when it fell. It use to take the One and a half days to cut down one tree and buck it into 20-30 ft long lengths

In the mid 50s the Teles Smith arrived and despite only using it 4 hours a day - the rest of the time was sharpening (it had very soft chains) and fiddling with the engine - they were able to cut down 4 trees a day. Because the TS was so heavy the powerhead end could not be lifted to start the scarf with the bar level, Instead the operator at the helper hand end used to lift the outboard end of the bar up high above his head and then pull the end down into the tree. As dad was tall than Charlie he got this job.

In 1959 dad got his first one man saw, a McCulloch with a 42" bar. These were very reliable saws with much better chains and he alone could cut down 8 trees a day. He had two of these saws and used to carry both through the bush along with fuel and oil, and a hessian bag containing steel wedges, chain sloops tools and two axes and a water bottle. This was when dad used to take me out with him but I was only about 6 years old and all I could carry was the fuel and oil. I also made the fire for "Billy Tea" and when I got older rode shotgun (on the top of the diesel fuel tank behind the driver) on the D9 dozer which used to drag the fallen and bucked logs into the truck loading area. My job was to jump off the back of the moving dozer and hook the chain or wire rope around the log. Then run after the dozer towing the log and jump onto the back of the moving tracks so they carried me back up to the level of the fuel tank where I'd jump over onto the fuel tank - OHS nightmares when I think about it.

At this cutting speed and with about 100 other fallers at work in the same are of forest it came down in swathes. After a year of this the local sawmills had enough logs on site for two years worth of milling and all timber falling contracts were cancelled. Dad moved to another town and managed to get back into falling for a few years before he was badly injured in a logging truck accident.

The Teles Smith was sold in 1967 and used as a boat motor. Dad kept the bar until some time in the 70s and got rid of it without telling me.

Years later I went to look for it and was very disappointed to see it had gone.

Some more info in this post

http://www.arboristsite.com/communi...-how-to-cut-thread.119821/page-2#post-1922578

Then they would cut the scarf with axes. some of trees were so massive that they had to crawl inside the scarf to complete the cut. Charlie was smaller than dad so he dis that. The the cross cut from behind and jump and run for your life when it fell. It use to take the One and a half days to cut down one tree and buck it into 20-30 ft long lengths

In the mid 50s the Teles Smith arrived and despite only using it 4 hours a day - the rest of the time was sharpening (it had very soft chains) and fiddling with the engine - they were able to cut down 4 trees a day. Because the TS was so heavy the powerhead end could not be lifted to start the scarf with the bar level, Instead the operator at the helper hand end used to lift the outboard end of the bar up high above his head and then pull the end down into the tree. As dad was tall than Charlie he got this job.

In 1959 dad got his first one man saw, a McCulloch with a 42" bar. These were very reliable saws with much better chains and he alone could cut down 8 trees a day. He had two of these saws and used to carry both through the bush along with fuel and oil, and a hessian bag containing steel wedges, chain sloops tools and two axes and a water bottle. This was when dad used to take me out with him but I was only about 6 years old and all I could carry was the fuel and oil. I also made the fire for "Billy Tea" and when I got older rode shotgun (on the top of the diesel fuel tank behind the driver) on the D9 dozer which used to drag the fallen and bucked logs into the truck loading area. My job was to jump off the back of the moving dozer and hook the chain or wire rope around the log. Then run after the dozer towing the log and jump onto the back of the moving tracks so they carried me back up to the level of the fuel tank where I'd jump over onto the fuel tank - OHS nightmares when I think about it.

At this cutting speed and with about 100 other fallers at work in the same are of forest it came down in swathes. After a year of this the local sawmills had enough logs on site for two years worth of milling and all timber falling contracts were cancelled. Dad moved to another town and managed to get back into falling for a few years before he was badly injured in a logging truck accident.

The Teles Smith was sold in 1967 and used as a boat motor. Dad kept the bar until some time in the 70s and got rid of it without telling me.

Years later I went to look for it and was very disappointed to see it had gone.

Some more info in this post

http://www.arboristsite.com/communi...-how-to-cut-thread.119821/page-2#post-1922578

IyaMan

Addicted to ArboristSite

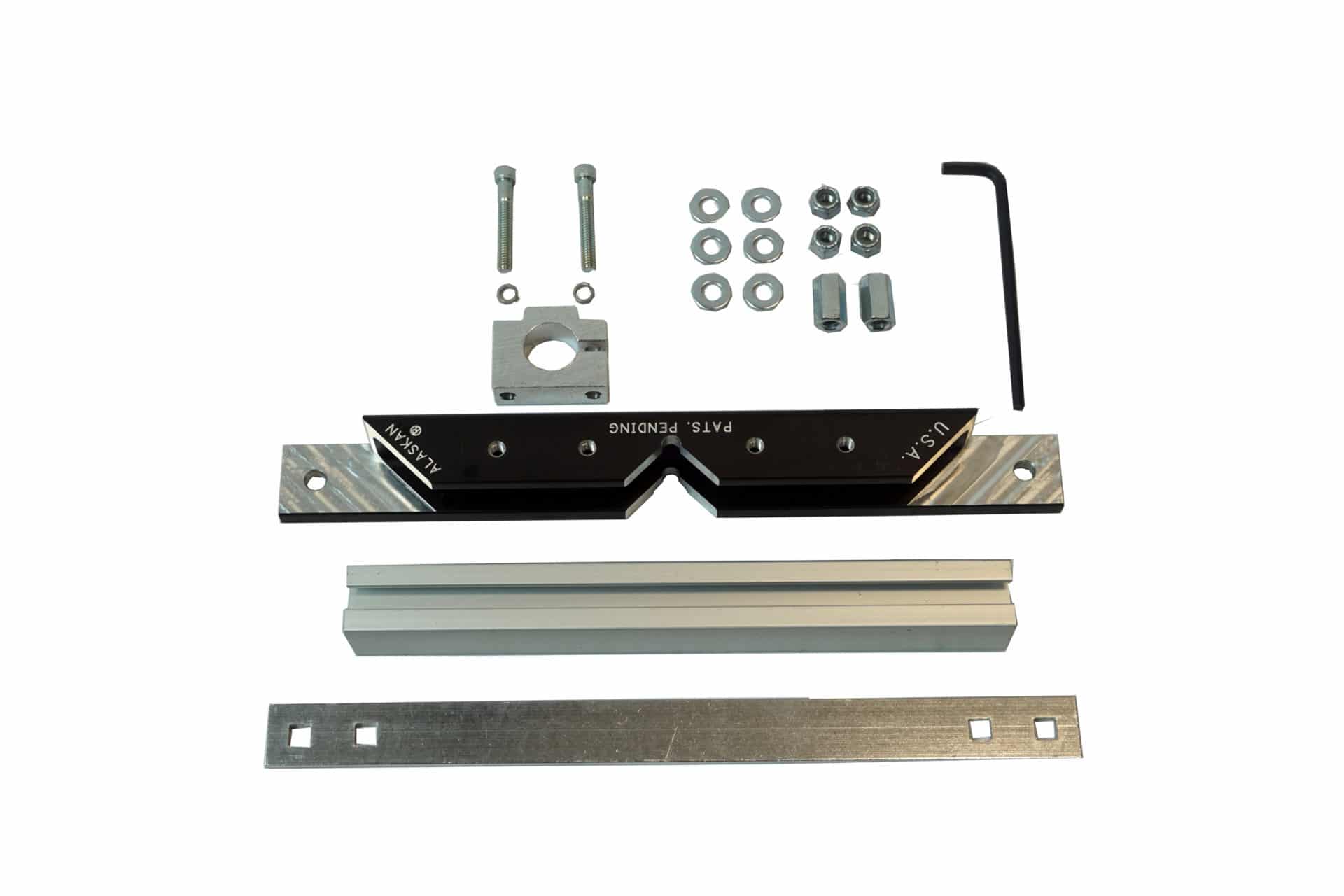

Brackets used to for post mounts and attachment to the rails.

It may be worth mentioning that Granberg has updated its end bracket design in the past year. Also, the clamp for the horizontal tubular cross-pipe is now screwed on separately instead of being all one piece.

I was just wondering how large the Chinese Alaskan mill is offered. If it's cheaper than the Granberg I would entertain buying a mid 40" mill. I searched the internet and could not find who sells them or what sizes they are offered in.

JohnWayne

ArboristSite Member

I was just wondering how large the Chinese Alaskan mill is offered. If it's cheaper than the Granberg I would entertain buying a mid 40" mill. I searched the internet and could not find who sells them or what sizes they are offered in.

I have found them on eBay in 24" and 36" lengths, nothing larger than that. In the end if you can find the longer rails reasonably priced, you can just take all the parts off a 24" mill and have a larger mill.

Sent from my iPhone using Tapatalk

Great story Bob, and like the family history. My parents were thinking of moving to Australia in the mid 50's. I don't know who they were in contact with. May have been the Australian embassy in Wash D. C. We did a lot of tree work for the embassies back then. Anyway, they offered to pay all of our relocation and transport fees, and guaranteed a job upon arrival. The only thing they would not pay for was converting your vehicles to right hand drive. Dad had just bought a new Pontiac and wasn't going to leave it, so we stayed here. Otherwise, we might be neighbors, Joe.

I have found them on eBay in 24" and 36" lengths, nothing larger than that. In the end if you can find the longer rails reasonably priced, you can just take all the parts off a 24" mill and have a larger mill.

If it still helps, I just upgraded my Chinese eBay mill to 42" rails using an extrusion from a local aluminium place. It's not identical to the stuff that comes with the mill - missing the cross brace bit and is slightly wider do the bolts are a bit trickier to tighten, but it only costs $40 for 6 metres (Ullrich aluminium)! Ask for "sign track/channel" - in Australia, it's the extrusion the use on the back of street signs.

For the round tube I just used water pipe from bunnings.

Just milled 4x2.5m Ironbark slabs this arvo with it, and it works a treat!

Ed: search for "backing channel" in here.

Ed2: just realised you're in the States, but I imagine there's something similar there.

Similar threads

- Replies

- 15

- Views

- 5K

- Replies

- 10

- Views

- 1K

- Replies

- 21

- Views

- 2K