Nice! Is that planetary gear reduction?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Homelite Chainsaws

- Thread starter briantutt

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

From a ad on Marketplace for a Homelite.

I hate seeing this. Even if he did misspell ether and carb.

"Will run on either needs cab cleaned has trash in carb from setting."

I hate seeing this. Even if he did misspell ether and carb.

"Will run on either needs cab cleaned has trash in carb from setting."

Nice! Is that planetary gear reduction?

Yes, has a itty-bitty planetary in the cover and a 3/8x8 sprocket.

Wow, I thought only the Wright saws offered PGR.Yes, has a itty-bitty planetary in the cover and a 3/8x8 sprocket.

My first saw 44 years ago was a XL-12. I still have it and use it some to keep it in good working order.

Last night I saw one for $30 on Marketplace. I live in central Virginia and the saw was near Hickory, NC.

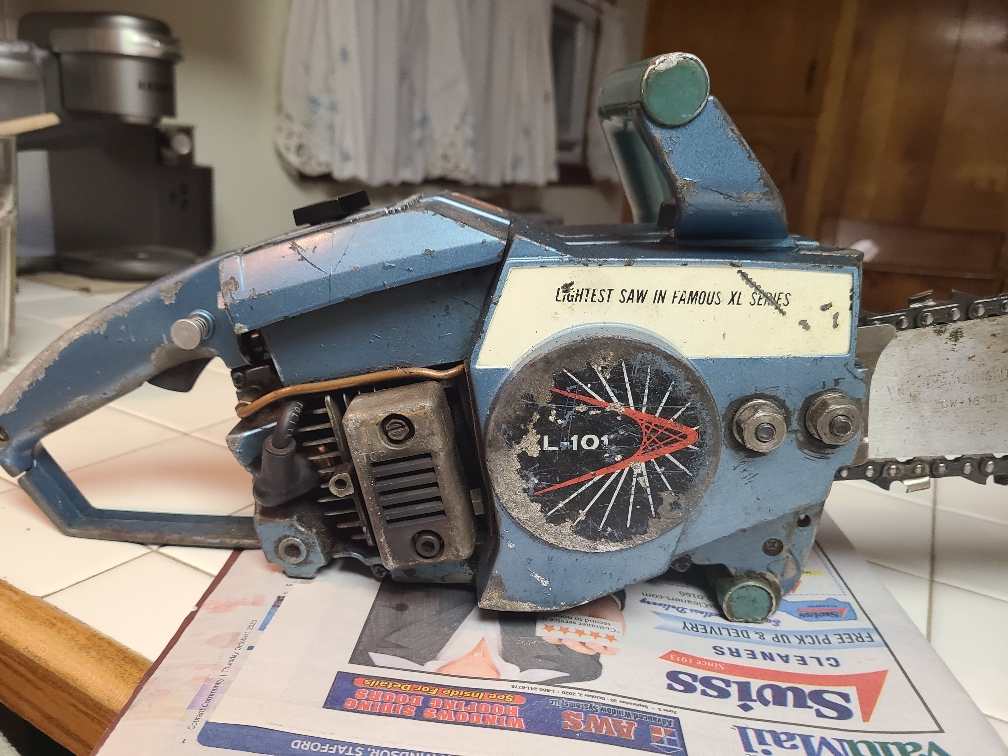

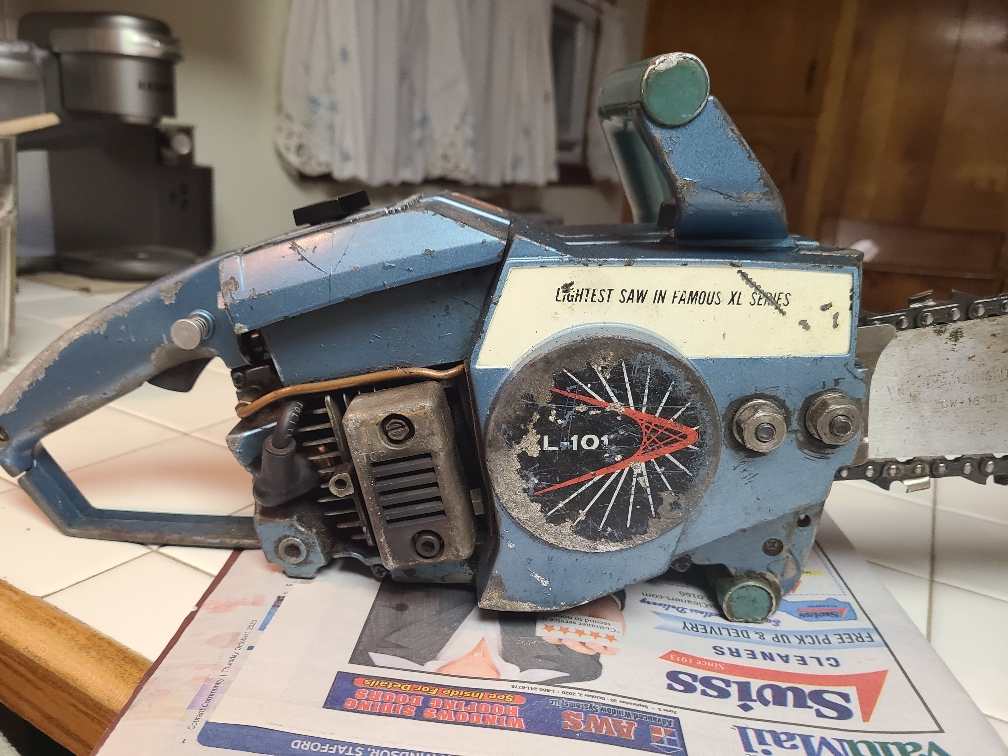

So my cuz Jesse lives in Hickory. I asked him to check on it and he sent these picks just now.

Jesse said the compression feels good and it needs a spark plug insulator cap.

So with a little carb work and insulator it may live again.

I was buying it for parts, but I may still be looking for a parts saw.

It was born in 1979.

Thanks for looking.

Clint

Last night I saw one for $30 on Marketplace. I live in central Virginia and the saw was near Hickory, NC.

So my cuz Jesse lives in Hickory. I asked him to check on it and he sent these picks just now.

Jesse said the compression feels good and it needs a spark plug insulator cap.

So with a little carb work and insulator it may live again.

I was buying it for parts, but I may still be looking for a parts saw.

It was born in 1979.

Thanks for looking.

Clint

Treehunter2111

ArboristSite Lurker

What’s the secret of getting stuck screws out of a saw when PB blaster isn’t working

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

What’s the secret of getting stuck screws out of a saw when PB blaster isn’t working

Sent from my iPhone using Tapatalk

Heat.

Treehunter2111

ArboristSite Lurker

Heat.

The saw has a magnesium case will that be a problem?

Sent from my iPhone using Tapatalk

I've been using Kroil for decades. It's the best I know of for stuck screws and bolts. It creeps into one millionth inch spaces.What’s the secret of getting stuck screws out of a saw when PB blaster isn’t working

Sent from my iPhone using Tapatalk

http://www.kanolabs.com/msn/?msclkid=8c0722c5eea6135a1e597db2179dc11dAmazon has it also.

Good luck.

The saw has a magnesium case will that be a problem?

Sent from my iPhone using Tapatalk

NO. They used to flame weld mag. It's magnesium dust and very fine metal that ignites. I use a fine tip soldering iron to soften loctite or help free up stuck bolts. Hold the iron on the fastener for a good period of time so it's gets quite hot. A flame is quicker but won't do your paint any favors.

Kroil or some other penetrating oil is good too as Clint53 suggested.

A 50/50 ATF and acetone mix has been known to outperform may of the commercial penetrating products for freeing up stuck/rusty fasteners. And ditto on the heat. The mag is softer than the fastener and will expand at a faster rate, hence the reasoning behind heating the fastener and not the magnesium. On the other hand, (and as stated), heating the magnesium will be much faster at the possible expense of the paint.

An impact tool also goes a long way. I have a 12 Volt 1/4" drive Bosch that usually works for me..., even with flat head screws if used carefully. Anything larger may run the risk of breaking off the head of the fastener.

An impact tool also goes a long way. I have a 12 Volt 1/4" drive Bosch that usually works for me..., even with flat head screws if used carefully. Anything larger may run the risk of breaking off the head of the fastener.

If facing those Posidriv screws, they can be a real fight. I have never been able to pick up the correct driver and ruined more than a few trying to use a Phillips. An manual impact screwdriver is favoured by many, but I have yet to pick up one. Have had to drill a few stripped heads off and resort to vice grips to turn the stubs out.

Well I'm not happy.

I've been studying porting and timing hard and I am almost ready to tear down a saw.

I had planned on starting with my first saw, a XL-12 from 44 years ago, but it still runs good and I didn't want to screw it up.

So I had the bright idea of buying two 300's on Marketplace. 60 bucks for both. My plan was to use one for parts if needed.

I had not ever held a 330 before, so I knew very little about them.

I drove 192 mile round trip to get them today.

When I got home I tried to fire up the one with the best compression. It was stubborn and didn't want to start.

I removed the carb/air filter cover to put some gas/oil mix in the carb. I immediately didn't like what I saw.

The 330 has the smallest air intake and filter I have ever seen.

It's not going to be a good saw to port unless I come up with a better and bigger air filter system.

Thanks for reading.

I've been studying porting and timing hard and I am almost ready to tear down a saw.

I had planned on starting with my first saw, a XL-12 from 44 years ago, but it still runs good and I didn't want to screw it up.

So I had the bright idea of buying two 300's on Marketplace. 60 bucks for both. My plan was to use one for parts if needed.

I had not ever held a 330 before, so I knew very little about them.

I drove 192 mile round trip to get them today.

When I got home I tried to fire up the one with the best compression. It was stubborn and didn't want to start.

I removed the carb/air filter cover to put some gas/oil mix in the carb. I immediately didn't like what I saw.

The 330 has the smallest air intake and filter I have ever seen.

It's not going to be a good saw to port unless I come up with a better and bigger air filter system.

Thanks for reading.

I have two really nice 330's, try to find a 360 they're always coming up for sale

Sent from my SM-G986U using Tapatalk

Sent from my SM-G986U using Tapatalk

So this is my newest saw, a XL-101 and it's in fantastic condition mechanically and not too shabby cosmetically. I tore it down and cleaned it up removed and rebuilt the carb after the ultrasonic bath, I had the OEM Walbro K10-SDC kit but needed the accelerator pump diaphragm so off to feebay I went and got it along with the airbox gasket.

I'm actually surprised at the amount of compression and how clean the P&C are.

So everything is back together loose fit minus the carb, new fuel line and filter along with a duck valve in the fuel tank breather. I replaced the pull cord after I removed the recoil spring and cleaned the mess in there. Cleaned and reset the points.

Sent from my SM-G986U using Tapatalk

I'm actually surprised at the amount of compression and how clean the P&C are.

So everything is back together loose fit minus the carb, new fuel line and filter along with a duck valve in the fuel tank breather. I replaced the pull cord after I removed the recoil spring and cleaned the mess in there. Cleaned and reset the points.

Sent from my SM-G986U using Tapatalk

It's not going to be a good saw to port...

There are lots of better choices for learning how to do basic port work than old Homelites. Husky 50 series saws come to mind..., even the later 340/350 clamshells. Stihl 024's/026's are another great candidate.

And pay close attention to the intakes on those particular Homelites as they're notorious for turning into jelly.

Thanks PogeThere are lots of better choices for learning how to do basic port work than old Homelites. Husky 50 series saws come to mind..., even the later 340/350 clamshells. Stihl 024's/026's are another great candidate.

And pay close attention to the intakes on those particular Homelites as they're notorious for turning into jelly.

I don't have any Husky's. Nothing against them at all.

Homelite's is where my heart is because that's what I started with in 1976.

My plan is mind porting and timing. If it runs and is dependable I'm happy. Then I will move on to something different.

So this is just a learning starting point. I will only be doing my saws and no others. I will only be doing it on the older saws 50 to 70 cc. I have no interest in hot rodding big saws.

Thanks for the advice on the intakes.

Clint.

I'm in search of a Tilly HS-135C or B for this damned XL-98 if anyone happens to have one in their bucket of carbs..., or a viable alternative, though the governed fixed high circuit of the 135 is pretty specific to the XL-98's particular use as a chop saw. The one on the saw will run off the fixed jet high circuit all day long at operational RPM's. It will simply not idle without extreme adjustment of the L jet to the rich side (like three turns out). Then it's useless on throttle up which is leading me to believe there's still a low circuit issue even after a couple of USC cycles and new diaphragms. But the good news is, it really didn't need bearings or seals even though I replaced em anyway. And the brand new roller bearing had the exact same play as the original one. Go figure.

Yes, the saga continues...

TIA for any help in the carb hunt.

Yes, the saga continues...

TIA for any help in the carb hunt.

So will the chop saw carburetor work? I know of 1 in a scrap yard.I'm in search of a Tilly HS-135C or B for this damned XL-98 if anyone happens to have one in their bucket of carbs..., or a viable alternative, though the governed fixed high circuit of the 135 is pretty specific to the XL-98's particular use as a chop saw. The one on the saw will run off the fixed jet high circuit all day long at operational RPM's. It will simply not idle without extreme adjustment of the L jet to the rich side (like three turns out). Then it's useless on throttle up which is leading me to believe there's still a low circuit issue even after a couple of USC cycles and new diaphragms. But the good news is, it really didn't need bearings or seals even though I replaced em anyway. And the brand new roller bearing had the exact same play as the original one. Go figure.

Yes, the saga continues...

TIA for any help in the carb hunt.

Similar threads

- Replies

- 19

- Views

- 975