You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Huztl MS660

- Thread starter Kyler Monares

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

My $15 wildthing worked great for cutting up my cracked fiberglass hot tub and it still works!If anyone's got a 150$ poulan wildthing I can help you with it in the meantime while we wait on parts I didn't know I needed. Those parts are pretty consistent over the years

i spit on my grand daddys fence and it knocked my on my behind. i think bite my tongueAnd putting in a invisible dog fence

Rocketross57

Junk Enthusiast

I too have jumped on the train after reading this thread. I have to say, I am excited to see what I come up with after putting some work into it. I don't mind working out kinks. I've never owned a new saw so working out kinks is something I'm used to and enjoy doing. I like a challenge, and after mine is done I hope I will have a decent almost 6 cube saw that I can use. Can't wait for it to show up. Ordered on the 5th.

Sent from my LGL41C using Tapatalk

Sent from my LGL41C using Tapatalk

I hate to see all you fellers upset on here. I'm new to the group and only joined because I read this and I thought the concept of building a chainsaw from a box of pieces was awesome and probably the DIYest way of getting a cool saw. I've read this thread in it's entirety almost twice now, actually taking notes this last time. I've learned a lot, asked a lot of questions and got a lot of help from some smart people. I have no idea what my box of parts is gonna be like when It shows up but I'm pretty sure with what I've learned here and hopefully with some more help I can get it running great. Sorry for the long post, just got sentimental I guess. Reading 83 pages of this stuff kind of makes you feel like you know a bunch of folks.

we love you too, your post was just right. watch out for those posts that span a whole page, their wife's are ignoring them.

Rocketross57

Junk Enthusiast

Pretty much start to finish. Nothing has detered me though.

Sent from my LGL41C using Tapatalk

Sent from my LGL41C using Tapatalk

Consistency is a good baseline, we can all work with consistency even if the part is not right as long as it's consistently not right in the same way you can work through that...it's when it's inconsistent that we have real challenges. Consistently inconsistent is not a good baseline, when the parts are sourced from different suppliers who have only a passing understanding or care about consistency it's very difficult to work through and gets quite frustrating. This is really the only frustration being expressed here.

Some folks are ok with each saw being a unique puzzle because they like solving puzzles for the sake of solving puzzles. Some folks are ok with discovering workarounds and don't mind performing the workaround every time they find the need. Both can lead to some impressive creativity and problem solving. But for every one of us, irrespective of which approach we're comfortable with, the expected outcome is a functioning saw. If we don't get a functioning saw then we're all just wasting our time. For me, if the path to a functioning saw is different each time I'll completely lose interest in building saws because they become long term problems, no predictability in function or dysfunction. I can get that at work, flat out don't need it in my hobby.

Some folks are ok with each saw being a unique puzzle because they like solving puzzles for the sake of solving puzzles. Some folks are ok with discovering workarounds and don't mind performing the workaround every time they find the need. Both can lead to some impressive creativity and problem solving. But for every one of us, irrespective of which approach we're comfortable with, the expected outcome is a functioning saw. If we don't get a functioning saw then we're all just wasting our time. For me, if the path to a functioning saw is different each time I'll completely lose interest in building saws because they become long term problems, no predictability in function or dysfunction. I can get that at work, flat out don't need it in my hobby.

Rocketross57

Junk Enthusiast

Well said sir.Consistency is a good baseline, we can all work with consistency even if the part is not right as long as it's consistently not right in the same way you can work through that...it's when it's inconsistent that we have real challenges. Consistently inconsistent is not a good baseline, when the parts are sourced from different suppliers who have only a passing understanding or care about consistency it's very difficult to work through and gets quite frustrating. This is really the only frustration being expressed here.

Some folks are ok with each saw being a unique puzzle because they like solving puzzles for the sake of solving puzzles. Some folks are ok with discovering workarounds and don't mind performing the workaround every time they find the need. Both can lead to some impressive creativity and problem solving. But for every one of us, irrespective of which approach we're comfortable with, the expected outcome is a functioning saw. If we don't get a functioning saw then we're all just wasting our time. For me, if the path to a functioning saw is different each time I'll completely lose interest in building saws because they become long term problems, no predictability in function or dysfunction. I can get that at work, flat out don't need it in my hobby.

Sent from my LGL41C using Tapatalk

Chris3558

ArboristSite Lurker

I got my saw back up and running after the loose flywheel nut and broken keyway issue. Still on first frst tank of fuel. I have followed some tuning tips from utube. I did pressure test and vacuum test the saw before starting and all is good. I am also running a 40:1 NON OXY Premium with Stihl Ultra oil mix. The problem is getting it to want to idle below 3200 rpm's. I understand the saw needs to get broken in, I have the high speed setting around 12800 and want to keep it on the rich side. From say 3200 rpms.....the saw responds great! Blip the throttle and it revs with no hesitation and right now! Let it idle at 3200 - 3300 for a few minutes, then hit the throttle and it kills. I know Weimedog has thrown the towel in on these kit carbs and I am starting to see why, but before I do.....was hoping I can make it work?? I have the idle screw out one full turn. I have tried the proceedure where you lean it out to 3700 rpms and turn the LA down to 3300......from there richen up the L screw until you reach 2500 rpms. Not going to happen. Once I get close to 3 grand with the L screw, the rpms want to fall until it dies?? I have checked both the H & L mixtures screws for straightness as the H speed screw was bent and I got it back to straight. Has anyone had similar issues? If so, have you had any luck making this kit carb work?? Other then this idle issue, it seems to perform decent. Thanks for your imput.But so far the only recurring issues for mine were carburetion, and I solved that with Walbro's.

I use the AM carb on one of mine. The throttle butterfly on mine was misaligned. And was causing air to flow around it causing a high idle like yours. I removed the carb and loosened the screw on the butterfly and you could see it close more. Tighten it back up and then see if that helps. May not be your problem but could be. If you don't follow or understand I can give you a Pic or video on what I'm saying. Hope that's it.

Edit: And check to make sure you have slack in your throttle rod. If it's bent it might have tension on it at idle.

Edit: And check to make sure you have slack in your throttle rod. If it's bent it might have tension on it at idle.

Chris3558

ArboristSite Lurker

Thanks Davhul, I know exactly what you mean. I did have that problem with the choke butterfly sometime sticking after the full choke setting and had to do exactly what you discribed. I will take a look at the throttle butterfly and throttle rod also. Thanks

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,086

I'm stumbling with when Farmertec ever really had a good "clone" that has now gone astray.

In the past they had some great parts and some weak parts and over time I would say both subsets have changed.

As far as the plastics and smalls go, I think they do a really nice job of putting that stuff together, same with gaskets and oil seals, even clutch bearings, ignition coils and flywheels.

For crankshafts I think NWP is vastly superior.

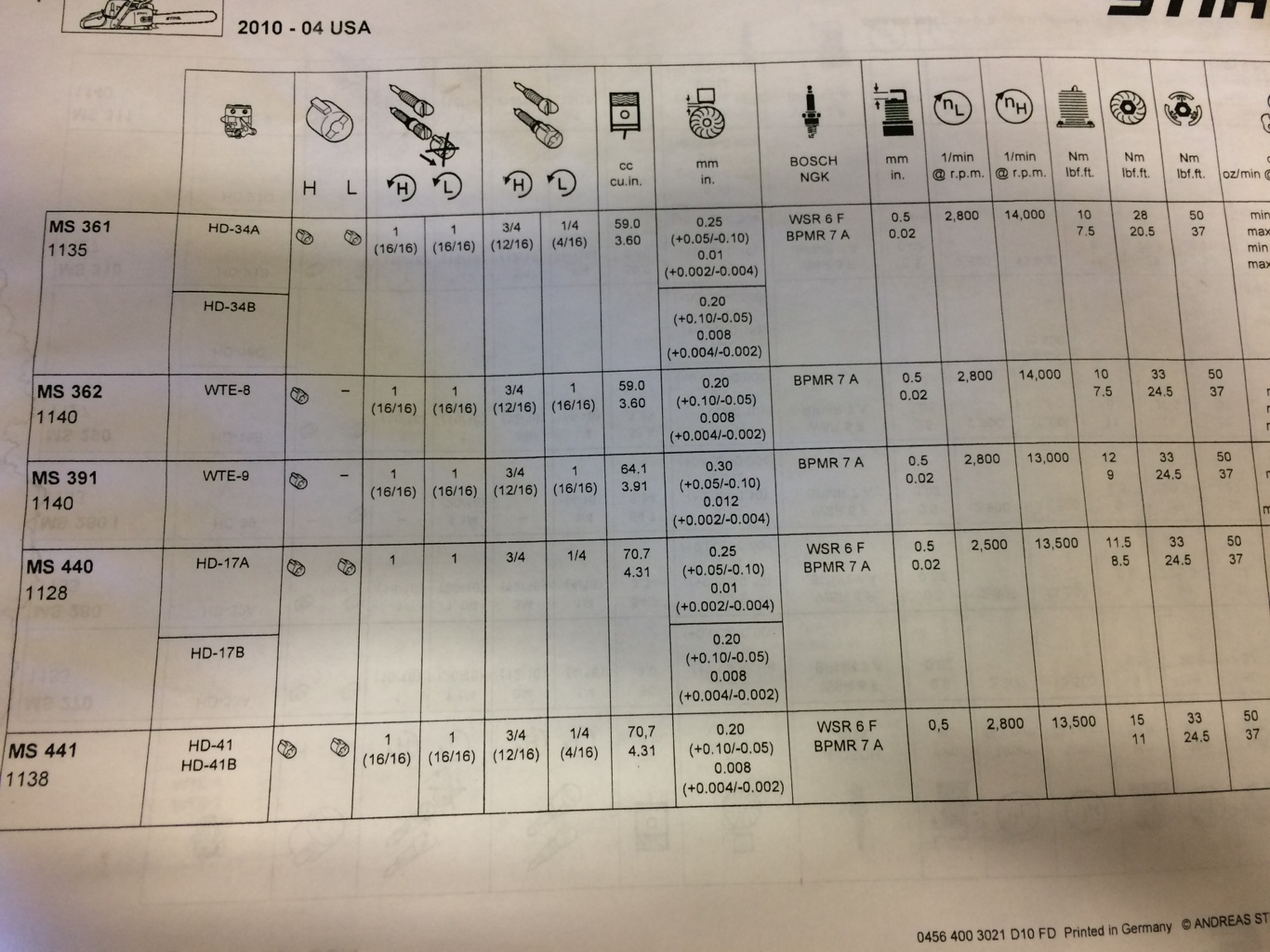

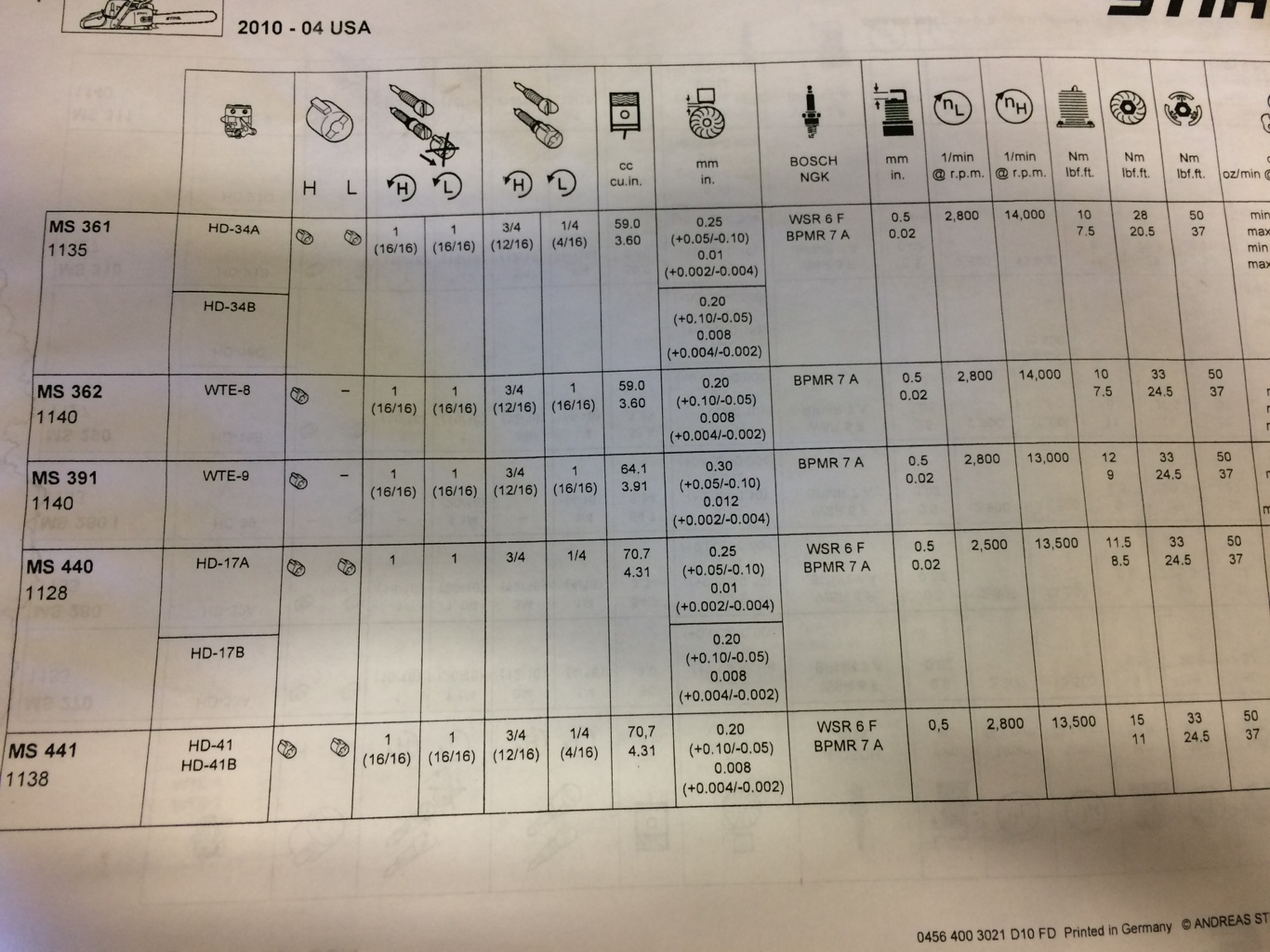

For carbs only The OEM Walbro wj-69 and Tillotson HS320 are really decent of what can be bought these days, though more carbs pop up almost monthly.

For cylinders at this point for the 660 I would put the current versions of these in this order.

1. OEM

2. Meteor

3. NWP (Taiwan not Bailey's house brand of the same name) Standard or Big Bore

4. Farmertec Big or standard bore about on par with most of the other lower end cylinder kits.

I would put the older Farmertec big bore about on par with the NWP.

I have some of the MMWS 066 and 064 cylinders in stock and have sold and given away several of each but I cant really comment on how they run because I haven't run one myself. The rings are Caber so that is a big plus though the circlips are just standard aftermarket. The port shape and timing is nice the fit and finish looks good though I have heard reports from others that they have seen cylinders with excess flash inside.

The brake linkage not working right is troubling, because all the brake components seemed to work well in the past, though thankfully I have never had occasion to verify the kickback sensitivity.

I'm sure given time they will get the few remaining missing pieces filled in, but honestly I cant imagine they will ever really ship a "clone" MS660.

Just too many hands making parts in too many factories all racing to be cheapest.

I hope I am wrong.

Dave

In the past they had some great parts and some weak parts and over time I would say both subsets have changed.

As far as the plastics and smalls go, I think they do a really nice job of putting that stuff together, same with gaskets and oil seals, even clutch bearings, ignition coils and flywheels.

For crankshafts I think NWP is vastly superior.

For carbs only The OEM Walbro wj-69 and Tillotson HS320 are really decent of what can be bought these days, though more carbs pop up almost monthly.

For cylinders at this point for the 660 I would put the current versions of these in this order.

1. OEM

2. Meteor

3. NWP (Taiwan not Bailey's house brand of the same name) Standard or Big Bore

4. Farmertec Big or standard bore about on par with most of the other lower end cylinder kits.

I would put the older Farmertec big bore about on par with the NWP.

I have some of the MMWS 066 and 064 cylinders in stock and have sold and given away several of each but I cant really comment on how they run because I haven't run one myself. The rings are Caber so that is a big plus though the circlips are just standard aftermarket. The port shape and timing is nice the fit and finish looks good though I have heard reports from others that they have seen cylinders with excess flash inside.

The brake linkage not working right is troubling, because all the brake components seemed to work well in the past, though thankfully I have never had occasion to verify the kickback sensitivity.

I'm sure given time they will get the few remaining missing pieces filled in, but honestly I cant imagine they will ever really ship a "clone" MS660.

Just too many hands making parts in too many factories all racing to be cheapest.

I hope I am wrong.

Dave

I would like to share the good news with you and give you more information than we have every had before. Arbortec.net was a champ and connected me with the "guy" @farmertec that controls the stuff we require and they have agreed to these 4 points and I will list them

so we have hit the jackpot, when you go to huztl.net and place an order. we will get what we need. also currently the prices on the website are as low as the guy who buys a pallet, he said he wants to sell lots. he has stuff we want and is going to work on these 4 points, he already has best price and he has our kits.

DD shared with you the info he had on the upcoming product introduction and the forum should have first look in many cases of the good stuff. farmer is very worried about the guys buying a kit and not having the right tools. i think he would worry less and ask fewer questions if you would post your issues along with a photo of your pressure readings before and after. those photos are important too. their Holzfforma brand will have some of the special tools we need.

He agreed to and likes the ideas:

1. shipping times are not clear. you dont announce your festivals and it makes us nervous worrying about our purchase when and if it shipped an when it will ship. you need to do better.

2. your kits are no longer clone quality and your suppliers are screwing us. you need to do better.

3. the farmertec jugs and pistons are pretty good on the outside, but not inside. you need to give your workers a foredom tool with the right fittings and clean up the inside, you need to do better

4. better communication between buyer and your customer service

i dont know how long this will take, but i will send him another email and try to be sure he understands these points because i do not speak a lick of chinese. i have given it my all and kept up with it and will make sure he has good information and then all we gotta do here forward is buy, farmertec will have our back. i dont think thats rings true for the big buyers but for us little guys all is ok.

too many words

so we have hit the jackpot, when you go to huztl.net and place an order. we will get what we need. also currently the prices on the website are as low as the guy who buys a pallet, he said he wants to sell lots. he has stuff we want and is going to work on these 4 points, he already has best price and he has our kits.

DD shared with you the info he had on the upcoming product introduction and the forum should have first look in many cases of the good stuff. farmer is very worried about the guys buying a kit and not having the right tools. i think he would worry less and ask fewer questions if you would post your issues along with a photo of your pressure readings before and after. those photos are important too. their Holzfforma brand will have some of the special tools we need.

He agreed to and likes the ideas:

1. shipping times are not clear. you dont announce your festivals and it makes us nervous worrying about our purchase when and if it shipped an when it will ship. you need to do better.

2. your kits are no longer clone quality and your suppliers are screwing us. you need to do better.

3. the farmertec jugs and pistons are pretty good on the outside, but not inside. you need to give your workers a foredom tool with the right fittings and clean up the inside, you need to do better

4. better communication between buyer and your customer service

i dont know how long this will take, but i will send him another email and try to be sure he understands these points because i do not speak a lick of chinese. i have given it my all and kept up with it and will make sure he has good information and then all we gotta do here forward is buy, farmertec will have our back. i dont think thats rings true for the big buyers but for us little guys all is ok.

too many words

you might have a bitter taste in your mouth cause you make are trying to make a living off these guys and others and you told me you were not happy with how your are treated and i do not blame you in the post i just made i said you are not getting any better pricing than me and you spend big money. i stand by what i said on a clone. a clone is a duplicate, not a bad copy, if i need to, thats what i mean. example if you took a starter from farmertec in august and laid it down next to a OEM it would look the same. that is not true this second, could be tomorrow, i think it will be soon. i have some photos of both. now the rope is not the same the rotors plastic cracked under the strain of high compression, but the pawls and spring was all good. the heart of the saw the case you could lay that same august case next to an oem and it was nearly identical. not so today.

you are splitting hairs for no reason here. we want a consistent well made saw part that when we need a replacement part we can go down to stihl buy a replacement part and bolt it on and go cut wood. and the case i made for the clone and its design still holds true until you get a crappy copy my august saw brake works as well as a oem.

the guy now understands he has some issues and now he gets it. and i was very direct and clear. he wants to understand and correct any issues. i dont think he knew.

you are splitting hairs for no reason here. we want a consistent well made saw part that when we need a replacement part we can go down to stihl buy a replacement part and bolt it on and go cut wood. and the case i made for the clone and its design still holds true until you get a crappy copy my august saw brake works as well as a oem.

the guy now understands he has some issues and now he gets it. and i was very direct and clear. he wants to understand and correct any issues. i dont think he knew.

Similar threads

- Replies

- 27

- Views

- 3K

- Replies

- 12

- Views

- 752