chadihman

Addicted to ArboristSite

Last week I posted about my 460 bb kit raking some plating off the cylinder and trashing the cylinder and the new meteor 660 piston that I made a pop up out of. The loctite fix on the crank bearing didn't work either and the clutch side case was cracked around the bearing.

I got a new bottom end for a really great price from fastLeo151. I just got the meteor jug and pston kit from Baileys today and I really like the looks of it. The port timing numbers are very close to oem. The plating looks really nice and the ex port is far from free porting. Very very nice kit and I think it's perfect for porting.

The port #'s are Ex at 105 deg ATDC IN 106 deg ABDC and TR 129 deg ATDC I'm shooting for 99 deg on ex 97 deg on in and 115 on the transfers.

The intake port needs lowered .132" to get me to 97 deg and the exhaust is .138" from free porting. All the port #'s were without a base gasket and the piston is lightly slapping the squish band. How much would you cut from the squish band with these #'s? Would it be crazy to cut the squish band .080" and the base .060". That would give me .020" squish. The comp would be pretty high I'm guessing but I would be safe from free porting and still have to grind a little on the bottom of the in port. The ex and tr would need to be raised quite a bit also. I want this saw to rip but dont want to blow the bottom end out.

I got a new bottom end for a really great price from fastLeo151. I just got the meteor jug and pston kit from Baileys today and I really like the looks of it. The port timing numbers are very close to oem. The plating looks really nice and the ex port is far from free porting. Very very nice kit and I think it's perfect for porting.

The port #'s are Ex at 105 deg ATDC IN 106 deg ABDC and TR 129 deg ATDC I'm shooting for 99 deg on ex 97 deg on in and 115 on the transfers.

The intake port needs lowered .132" to get me to 97 deg and the exhaust is .138" from free porting. All the port #'s were without a base gasket and the piston is lightly slapping the squish band. How much would you cut from the squish band with these #'s? Would it be crazy to cut the squish band .080" and the base .060". That would give me .020" squish. The comp would be pretty high I'm guessing but I would be safe from free porting and still have to grind a little on the bottom of the in port. The ex and tr would need to be raised quite a bit also. I want this saw to rip but dont want to blow the bottom end out.

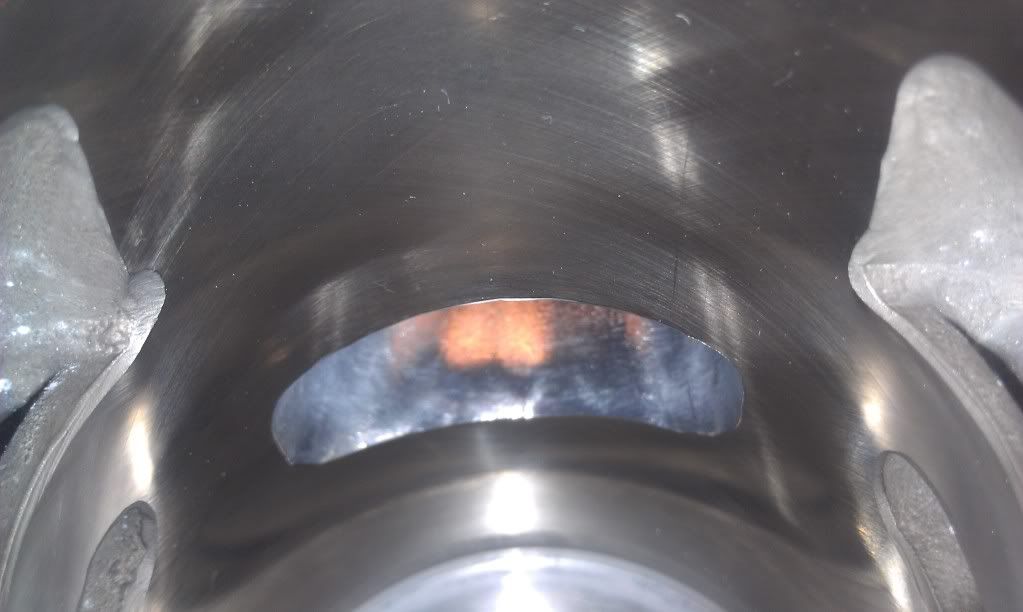

The base will get cut .058 next to get me a squish around .022. This is going to take some grinding to get the ports were I want them but it gets the intake pretty close to where I want it and the ex is safe from free porting. I guess I'll have to go back in and cut the combustion dome a little if the comp is to high. Here's a pic of that fat squish band.

The base will get cut .058 next to get me a squish around .022. This is going to take some grinding to get the ports were I want them but it gets the intake pretty close to where I want it and the ex is safe from free porting. I guess I'll have to go back in and cut the combustion dome a little if the comp is to high. Here's a pic of that fat squish band.