Magnumitis

ArboristSite Operative

- Joined

- Nov 24, 2012

- Messages

- 379

- Reaction score

- 415

waiting to see how you do the muffler mod. stock deflector?

Not really......spill the beans man.

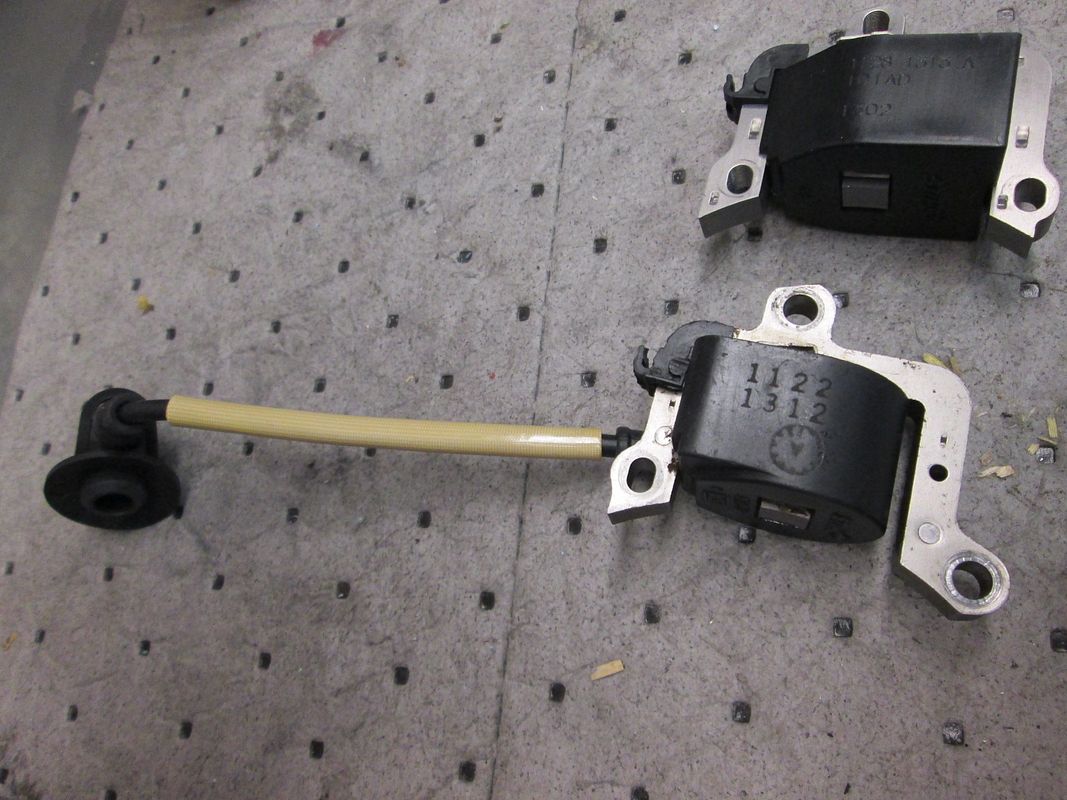

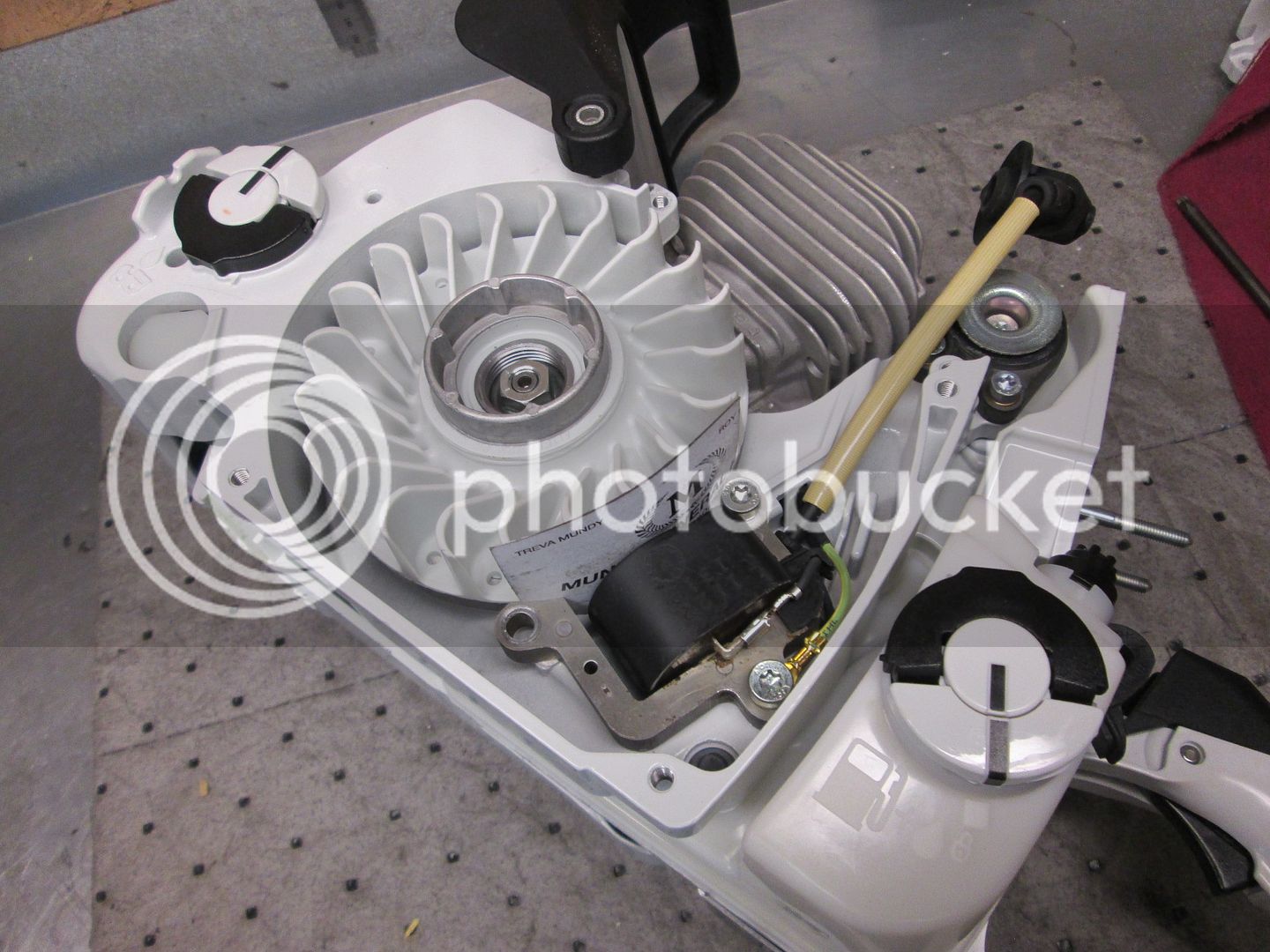

The 461 is Stihl's first use of a new idea they call "delayed scavenge." The transfers open when there is still a tad of pressure above the piston, and allow exhaust to start to backfill the transfers. Like a Strato engine, the incoming charge is preceeded by using something other than fuel to purge the chamber. In this case it is exhaust from the previous combustion event. When they did this, obviously they discovered temperature of the transfers is much hotter (since there is hot exhaust in there now.) Well this means more heat adjacent to the wrist pin in the cylinder, and consequently more heat there. Supposedly they were getting a strong running saw for a short time, and then the wrist pin bearing would fail. That little deflector is to splash cool fuel on the underside of the piston and give the pin bearing a fighting chance. Of course, it also takes up space and acts as a crank stuffer. They say it will run fine without the deflector in there, but the pin bearings will probably fail within MINUTES(!!!) YMMV. Have you tried one without the deflector yet?

A new and improved AS and now randy has action shots! Sweet!

Great job Randy. Can't wait to see the before and after vids!

I like your work space. Nice and tidy.

Thank you, and to Brad for stepping up to help a member. I belong to a few other online communities but none other compare to the comradere shared here. I wish I could contribute more to the forum with knowledge, but I am just learning the ways of the oil burners.

Thanks again.

Is this a raffle that anyone can get into off this site or do you have to be present at an event to win?

that ain't no problem,,,, I would French kiss her then hump the wild boar for that sawYou have to either kiss Hillary Clinton on the lips or kill a wild boar weighing over 400 pounds with a spear to be eligible to win.

Guys you all better get in on the donations, I have a mastermind built 461 and its a torque monster. I'm actually starting to like it more than my mastermind built 460.

Enter your email address to join: