RyanTowry_81

Educated redneck

First off i would like to say thank you for everyone out there making this site the wealth of knowledge it is! I have been lurking on here for some time before just recently becoming a member. I wont tell my wife that this new found addiction is all your guys fault...lol

A little background.

I am a process engineer by trade, a grease monkey at heart and as a son of a life time diesel mechanic and fellow gear head i have been tearing apart anything with a motor trying to make it faster since i could walk. I have been cutting fire wood with small homeowner saws most of my youth but never tore into them much, just enough tuning to keep the saws getting firewood. I have currently been cutting fire wood with a husqvarna 445 which was fine for me when i lived up in alaska and the biggest trees i ever cut were birch in the 12-18" range. now that i live in northern California cutting black oaks, fir and cedars she seems a little anemic. only mod i have done to the 445 is a muffler mod and bought the special splined tool to be able to richen her up.

so i wanted a bigger saw, like we all do, and started researching and since i already have a husky and there is a couple good local husky dealers i decided to stick with them. My search had me drooling over a 372 but it was out of my price range new so i decided to put the grease monkey skills to work and started looking for a project saw.

While looking on ebay i found this 365 special and it sounded like it needed a carb rebuild and possibly a top end so i threw in a low bid and walked away assuming it would go alot higher only to finjd out later i had won.

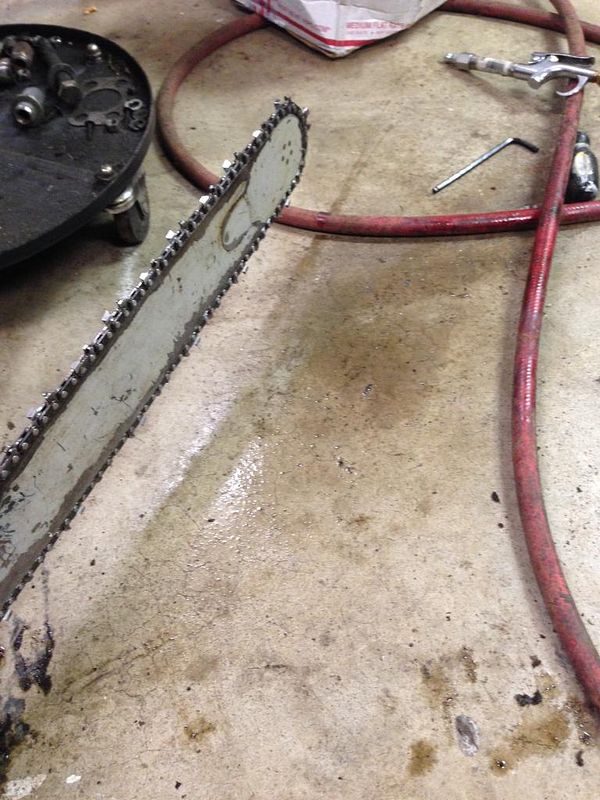

So the story from the seller is it has 120psi comp on his gauge and it would only idle for 5-10 minutes till warm then die. if you gave it throttle it would die. here is what i received:

and yes he did ship it in a Stihl box, that was kinda funny.

here is the name plate:

I am assuming this tag means it is a 2001 model?

also had this sticker on it:

A little background.

I am a process engineer by trade, a grease monkey at heart and as a son of a life time diesel mechanic and fellow gear head i have been tearing apart anything with a motor trying to make it faster since i could walk. I have been cutting fire wood with small homeowner saws most of my youth but never tore into them much, just enough tuning to keep the saws getting firewood. I have currently been cutting fire wood with a husqvarna 445 which was fine for me when i lived up in alaska and the biggest trees i ever cut were birch in the 12-18" range. now that i live in northern California cutting black oaks, fir and cedars she seems a little anemic. only mod i have done to the 445 is a muffler mod and bought the special splined tool to be able to richen her up.

so i wanted a bigger saw, like we all do, and started researching and since i already have a husky and there is a couple good local husky dealers i decided to stick with them. My search had me drooling over a 372 but it was out of my price range new so i decided to put the grease monkey skills to work and started looking for a project saw.

While looking on ebay i found this 365 special and it sounded like it needed a carb rebuild and possibly a top end so i threw in a low bid and walked away assuming it would go alot higher only to finjd out later i had won.

So the story from the seller is it has 120psi comp on his gauge and it would only idle for 5-10 minutes till warm then die. if you gave it throttle it would die. here is what i received:

and yes he did ship it in a Stihl box, that was kinda funny.

here is the name plate:

I am assuming this tag means it is a 2001 model?

also had this sticker on it: