Well, that's the first pic of a full wrap I've ever seen and I have to say OMG! I really like that a lot! My CAD has kicked in full tilt this morning so I'll have to crank some saws up, beg for parts, do something to satisfy the "CAD Monster" this afternoon. Why did y'all have to post so many pics of good lookin' 4000's? Have a great day everyone, and if anyone has a wrap handle they're willing to part with, please let me know. Suffering Max in Richmond!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nik's Poulan Thread

- Thread starter FATGUY

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Here’s another link to the 5200/5400/4200 crank seals. $3.04 ea. Beats the pants off any other distributor and no 2 week wait

https://3bgsupply.com/seals/shaft-seals/17x28-5x6tc-bx-dichtomatik-americas

https://3bgsupply.com/seals/shaft-seals/17x28-5x6tc-bx-dichtomatik-americas

I would buy one if they were available. I didn’t even know they were ever produced .I know where that full wrap handle is, in fact I know where 2 of them are. The owners are never going to let them go. It's my understanding that only a few were made and they make the way the 4000 feels in your hands is awesome. If I had a welder that would do aluminum I would make a few.

Welderman85

ArboristSite Operative

Need some tuning help. With a plastic strato saw. It doesn't seem to stay in tune. Every time I start it is different either rich or lean.

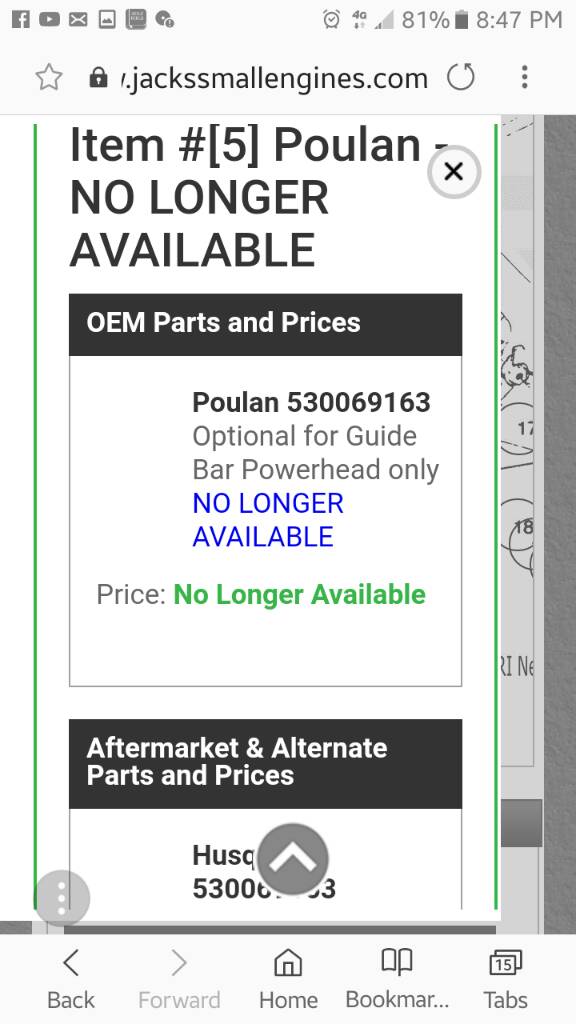

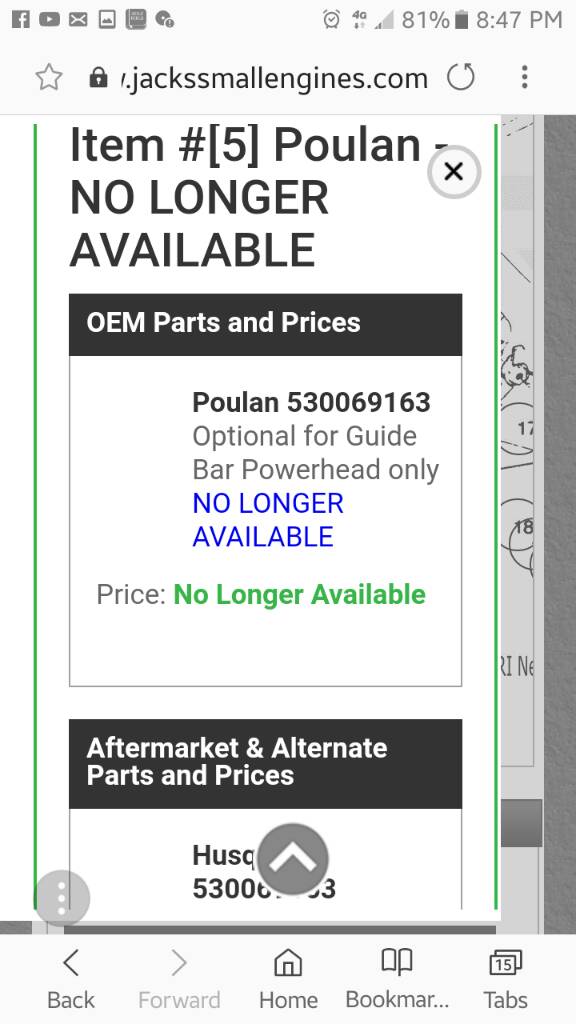

Looks pretty, nla.

Steve Sidwell

Steve Sidwell

Carb clean, fuel lines good, primer bulb good, no air in fuel lines?Need some tuning help. With a plastic strato saw. It doesn't seem to stay in tune. Every time I start it is different either rich or lean.

Steve Sidwell

Welderman85

ArboristSite Operative

I cleaned the carb a little bit ago , new fuel lines and primer bulb. I have not checked for bubbles in the fuel lines. What would that indicate. Thank you

Thick aluminum pipe and a pipe bender, you might be able to make one, just need to be able to weld aluminum and have nice welds.

Steve Sidwell

Steve Sidwell

I’m going to look into this full wrap setup. Friend of mine builds tube chassis’s for rock buggies and has a tube bender. I know he has a 1.00” die but I’m not sure how tight of a radius he can bend with it. I’ll see what I can come up with and report back

Screwbolts

Never to many Engines!!

I’m going to look into this full wrap setup. Friend of mine builds tube chassis’s for rock buggies and has a tube bender. I know he has a 1.00” die but I’m not sure how tight of a radius he can bend with it. I’ll see what I can come up with and report back

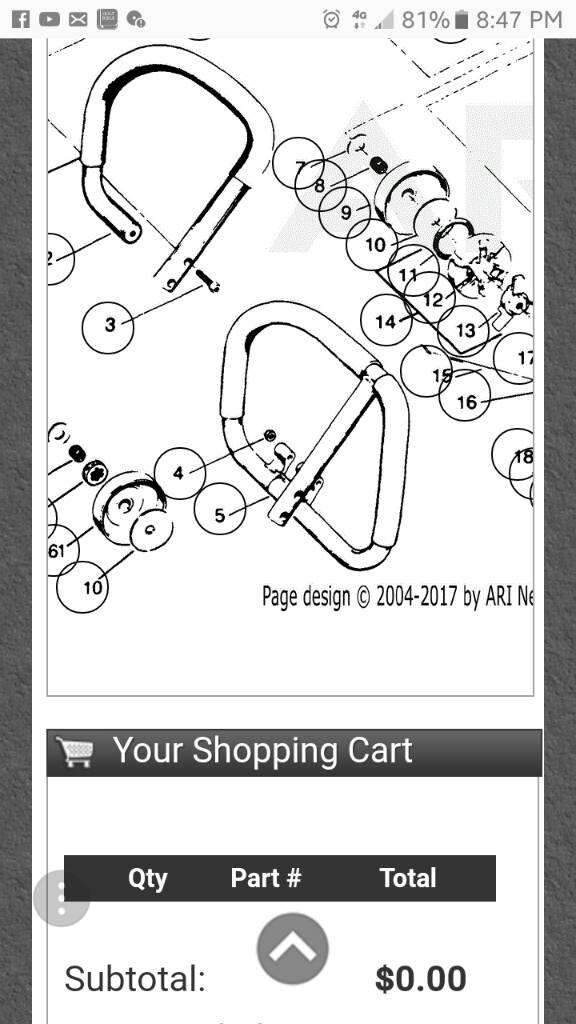

After you get the loop formed you will have to get a machinist maybe someone like Todd, to make you the two mounts that tie into the forward anti vibe mounts. Then have them welded to your tube and brace piece welded at the same time. Beg,borrow or steal one to get the dimensions for the mounting blocks shown in Steve's parts drawing. Middle of loop bottom side protruding out.

It is very self evident when looking at the drawing that one mount takes the place of the normal front hand mount that the 1/4" bolt threads into. The nut shown in the drawing is used in place of the front handle. The other mount clearly takes the place of the spacer that goes between the anti-vibe mounts that the same 1/4" bolt passes threw. The same bolt is used less the spacer and origonal front mount.

Ken

After you get the loop formed you will have to get a machinist maybe someone like Todd, to make you the two mounts that tie into the forward anti vibe mounts. Then have them welded to your tube and brace piece piece welded at the same time. Beg,borrow or steal one to get the dimensions for the mounting blocks shown in Steve's parts drawing. Middle of loop bottom side protruding out.

Ken

I have the machinist part covered, that’s my day job lol.

Oliver2150

ArboristSite Member

Got some time to do some measuring this afternoon. I used the popsicle stick trick. My Poulan 3800 is right at 1.880”.My craftsman 358.356090 came in it 1.873” best I measured. My craftsman 358.356091 came in at 1.874”. That tells me according to Todd that they are both 3700 bores more than likely.

They have to be thin ring to be a 3700

Oliver2150

ArboristSite Member

They have to be thin ring to be a 3700

These are both thick ring. Chrome piston.

That would be a great 3800 one of my favorite saws that with a little help are even better.

Oliver2150

ArboristSite Member

That would be a great 3800 one of my favorite saws that with a little help are even better.

Well that’s what I was originally hoping they were. I like my 3800. Been great up until today. Ran across some 40:1 Poulan synthetic oil mix earlier this weeks. I had been running 50:1 Stihl Ultra just for simplicity because I have Stihl equipment as well. I figured Poulan oil for Poulan saws why the hell not lol. Well stopped and got 2 gallons of 90 octane non ethanol today and mixed 2 bottles in. Filled the 3800 up and she will cut for about 10 minutes then bog down and die. Fire her back up and does the same thing. Pulled muffler off and checked piston for scoring and it looks beautiful. Guess I’ll have to tear into her.

Might just need a tune for the richer oil mix. Try putting a fresh plug in it and tune it again in the wood for that fuel mix.Well that’s what I was originally hoping they were. I like my 3800. Been great up until today. Ran across some 40:1 Poulan synthetic oil mix earlier this weeks. I had been running 50:1 Stihl Ultra just for simplicity because I have Stihl equipment as well. I figured Poulan oil for Poulan saws why the hell not lol. Well stopped and got 2 gallons of 90 octane non ethanol today and mixed 2 bottles in. Filled the 3800 up and she will cut for about 10 minutes then bog down and die. Fire her back up and does the same thing. Pulled muffler off and checked piston for scoring and it looks beautiful. Guess I’ll have to tear into her.

I say this because I use the stihl moto mix canned fuel in the saws I really care about, other equipment gets stihl hp ultra mixed with 92 non ethanol pump gas at 50:1. When I have used my 92 mix in the saws that use the canned fuel I have noticed a difference and even had one saw just up and quit like what you are experiencing. Fresh plug and a tune fixed it.

edit my 92 pump mix probably is closer to 40:1 than 50:1 plus there’s everything else they add to pump fuel

Air leak in the fuel line or carb getting air into the fuel system.I cleaned the carb a little bit ago , new fuel lines and primer bulb. I have not checked for bubbles in the fuel lines. What would that indicate. Thank you

Steve Sidwell

Similar threads

- Replies

- 1

- Views

- 483