Of almost all my Stihl collector saws, the start mechanism has tendency to "slip" during the starting procedure, due to the mechanical driver not engaging correctly.

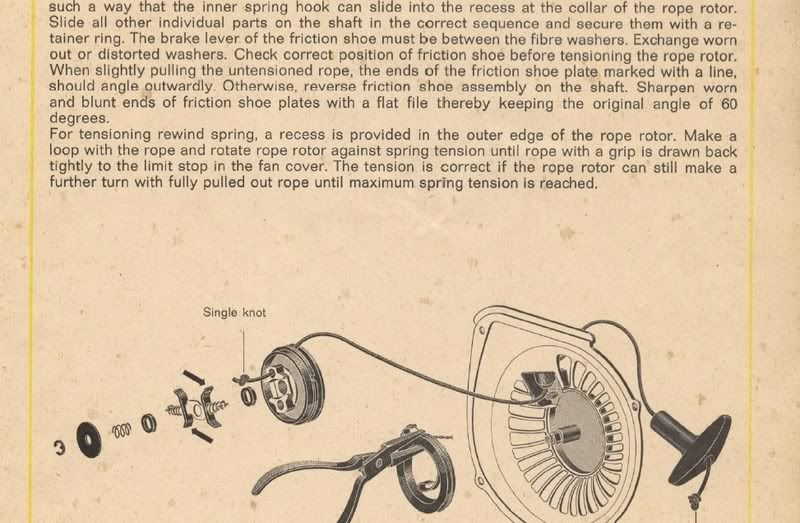

I have posted a pic of the mechanism that has to drive the hollow ring connected to the flywheel (washer and spring removed). The two plates connected to the rod slides externally once you pull the rope, and engage at the inner side of the pulley.

The rod movement, I suppose, is driven through friction, controlled by two seals and a spring.

On most of the older saws, the mechanism doesn't function well (the two fingers don't slide outwards). How can one remedy this problem ? Any help is appreciated.

I have posted a pic of the mechanism that has to drive the hollow ring connected to the flywheel (washer and spring removed). The two plates connected to the rod slides externally once you pull the rope, and engage at the inner side of the pulley.

The rod movement, I suppose, is driven through friction, controlled by two seals and a spring.

On most of the older saws, the mechanism doesn't function well (the two fingers don't slide outwards). How can one remedy this problem ? Any help is appreciated.