I have tasked myself to off season maintenance of our 4 Stihl chain saws for the Tahoe Rim Trail. The 026 has undergone different venting systems over the years. The tall vent on this early model I understand is bi-directional that air can go in and out of the tank. The problem is when you turn the saw tanks caps down the gas runs out of the vent.

Stihl 026 Serial Number: 2 23 393 980

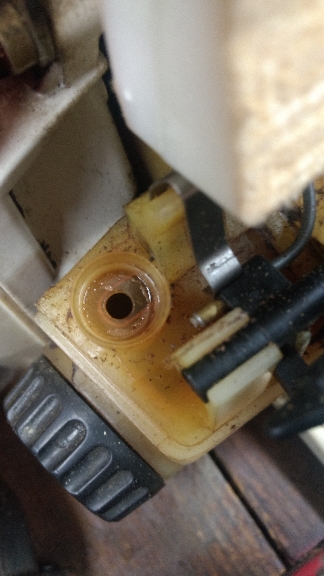

In the picture below the tank housing nipple has a slot. The nipple has a dimension OD ~0.3", ID ~0.22" where the vent pushes on.

I found a Technical Documentation dated February 1, 1995 for a modification but list for serial numbers starting with X 30 976 775. So that puts my saw too old.

Looking down the nipple there is a slotted hole that looks like something should go there. On the parts break out, parts number 28 and 22 could, but the inside diameter of nipple is ~0.22" so those parts need a small diameter unless it is number 22 and pushes in from the inside of the tank.

I also read and can't find the post, where a user put a gas hose on the nipple and attached a weed wacker vent. Willing to do that if the other route is not doable. Anyone remember that post?

We can't have gas flowing out of the vent into a hot saw with the possibility of starting a fire in the forest.

Attached is some helpful information.

Thanks, Patrick

Stihl 026 Serial Number: 2 23 393 980

In the picture below the tank housing nipple has a slot. The nipple has a dimension OD ~0.3", ID ~0.22" where the vent pushes on.

I found a Technical Documentation dated February 1, 1995 for a modification but list for serial numbers starting with X 30 976 775. So that puts my saw too old.

Looking down the nipple there is a slotted hole that looks like something should go there. On the parts break out, parts number 28 and 22 could, but the inside diameter of nipple is ~0.22" so those parts need a small diameter unless it is number 22 and pushes in from the inside of the tank.

I also read and can't find the post, where a user put a gas hose on the nipple and attached a weed wacker vent. Willing to do that if the other route is not doable. Anyone remember that post?

We can't have gas flowing out of the vent into a hot saw with the possibility of starting a fire in the forest.

Attached is some helpful information.

Thanks, Patrick