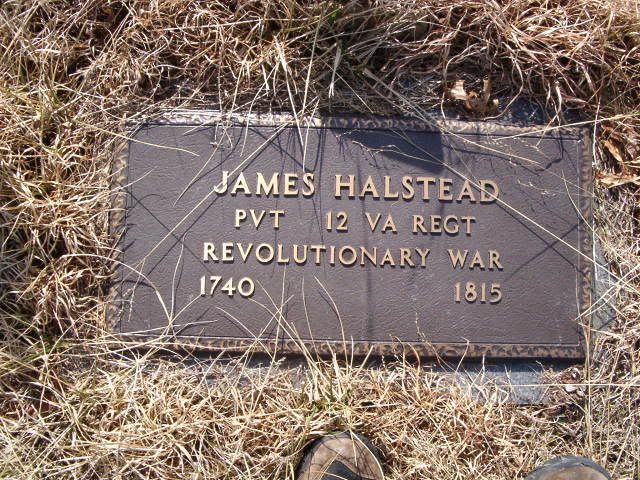

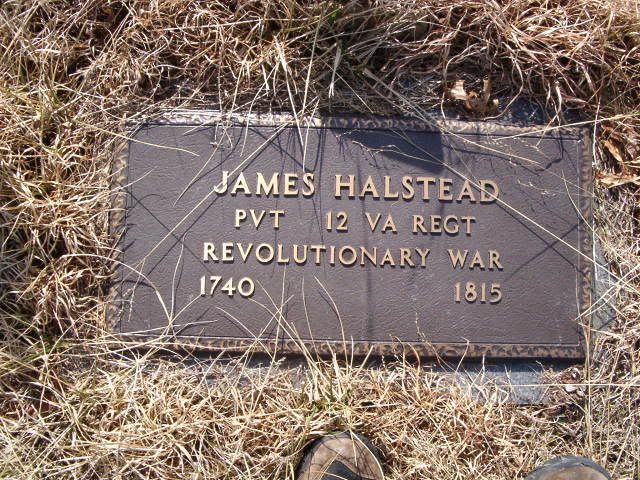

Eight generations ago.

How about a crappy cell phone pic of me standing on the other side of that same lighthouse about three years ago?

Doesn't look as cold in that pic.

That is one shiny mini-14, I like it.Here are some pics of my varmit gun. Ruger Mini 14 ranch, great for ground hogs and coyotes. Kevin

How about a crappy cell phone pic of me standing on the other side of that same lighthouse about three years ago?

Here are some pics of my varmit gun. Ruger Mini 14 ranch, great for ground hogs and coyotes. Kevin

Not sure about your neck of the woods, but most coyotes up here don't like all the Bling, Bling. I will say that I usually try to hide all the shiny stuff on a coyote rig.

Carlyle

How did you get that stainless so shiney. Bet it took a lot of polishing.I was 24 out 25 last year so that's an acceptable loss to me. I don't think they see meor maybe they do like it, to a fault.

Been planning on getting one for several years and my buddy who worked at Bass Pro alerted me that there was a sale plus I'd get his discount. Had all the parts bought allready and did all the work on it and took it back the next weekend. Cleaned and deburred the action as well so it's super smooth. They didn't believe it was the same gun till the ran the serial number. The BEST thing you can do for any gun is get a Hogue stock. Those give the best feel of any out there and there is NO slippage.

Here are some before pics

and an after

I don't use that clip while varmit hunting. I prefer the Eagle clips as they never miss feeding. Stainless isn't that hard to work with, it just takes time and practice

Looks like the bolt needs polishing, Is that a red dot scope.

How did you get that stainless so shiney. Bet it took a lot of polishing.

It looks awesome Kevin.I'm a machinist by daybut make a lot of street rod parts on the side and work with stainless mostly. Surface on this was basically bead blasted from the factory for the matte finish. I started with 320 grit, then 600, then 1000. Buff after that to a mirror finish. Sometimes you have to go to 2000 grit on larger flats but not needed on this. This was done in spare time in one week with working a full time job. It was actually a smaller job as some of the stuff gets real involved but no one would pay the cost of having it(gun) done and that's why you don't see it too often. Hard corners are sanded via ice cream sticks with double sided tape(trick).

"Looks like the bolt needs polishing, Is that a red dot scope."

You can't have to many rattlesnakes these days. Its good to keep a fresh supply.

Okay ODS9091 Here's some more for ya.

It'll look good when your finished, What caliber is it.To Stihlsawing:

It is a 1938 built Mauser-System. I will black-oxide finish like it was.

The red dot is a Aimpoint R1.

Cheers

Enter your email address to join: