terryknight

ArboristSite Operative

i am looking for opinions on chainsaw mills. i have access to 10 or so logs (oak and cherry) ranging from 10 ft to 30 ft and 15in to 26in in diameter. my brother and i would both like some of the wood for various products. right now my largest saw is a 044 with a 28in bar. I am not against getting a larger saw.

what mill(s) would you guys recommend?

are the guide bars/rails necessary?

what size saw would be the best?

this is the big one. i don't understand. what is the difference between regular chain and ripping chain?

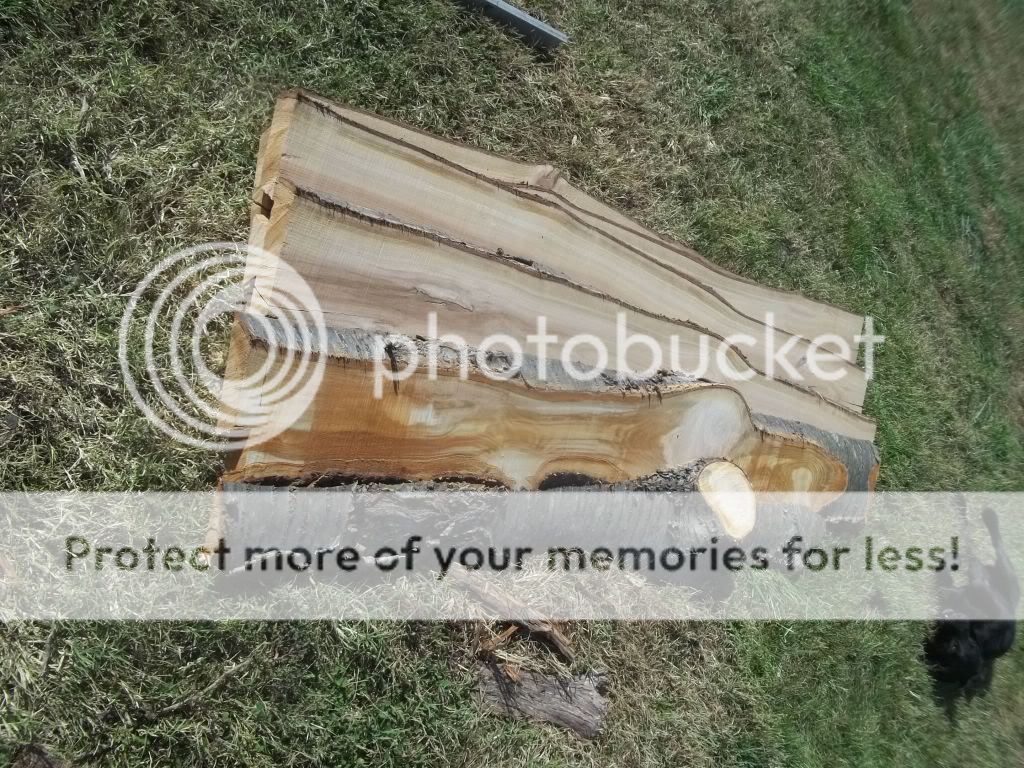

here are some pics of some of the wood

what mill(s) would you guys recommend?

are the guide bars/rails necessary?

what size saw would be the best?

this is the big one. i don't understand. what is the difference between regular chain and ripping chain?

here are some pics of some of the wood