Post #11What issue is it that you’re referring to?

Chainsawr also seems to indicate it was a change in the later 045 as well.

Post #11What issue is it that you’re referring to?

I was not initially planning to either, but based on the above and depending on the serial number I am wondering if I should.Ah I’m not planning on changing any of the oil drive setup, or were you just interested to see how this one was setup?

Honestly I’m still lost as to what you guys are really on about! I have read and re read and still can’t make sense. Long and short, if I replace something it will be like for like lolI was not initially planning to either, but based on the above and depending on the serial number I am wondering if I should.

If the oiler spur is enough to throw out the bearings ... hmm.

There was a design change part way through the 1115 series with the oiler spur gear.Honestly I’m still lost as to what you guys are really on about! I have read and re read and still can’t make sense. Long and short, if I replace something it will be like for like lol

do me a favour and just explain in laymen’s terms exactly what you guys are chatting about?

As mentioned, there is no "larger" or "smaller" case per se. Just a different bearing and bearing seat in the later case (of the two earlier style cases) which in turn determines the oil pump spur gear type,the larger case

I thought I explained all of that in post #11, but I'll jump back in to hopefully provide further clarification.Not quite, I was looking for information on the crankcase difference. I incorrectly guessed the larger case was for the .404 chain.

That not being the case and pogointhewoods mentioning the pto issue and in relation to the oil pump, I was trying to determine which oil spur was correct as the IPL does not differentiate between the two nor denote if one belongs to a specific version.

The clutch-rim sprocket I have not fully decided on yet. I was just trying to firm up internals.

The note about the oiler change/update is interesting, I'll likely have to wait until the saw is apart to determine which version it has. The question is how to tell the two spurs apart and if any of the other differences are unmarked on the IPL.

Is that arrow line a reference to the serial numbers with the updated component?

I'd like to see that service note.From what I can tell without reading the actual service note, the original was geared wrong. This causes an imbalance on the crankshaft causing the seal to fail.

As you can see, that may or may not be the way to go depending on the history of the saw and who may have worked on it along the way. Too many possibilities for incorrect parts to already be installed on these things by uninformed mechanics due to so many design changes throughout their history.if I replace something it will be like for like...

Hopefully that's all that's wrong with it!I probably found why the saw was sold

Wow, thanks, still perplexed, but will take the pictures you mention and go from thereThat pin is simply a 2.5 x 15.8mm needle roller and a replacement can be fashioned several ways. The original part # shows NLA when searched, but a local dealer may well still have a bag of em in a drawer somewhere.

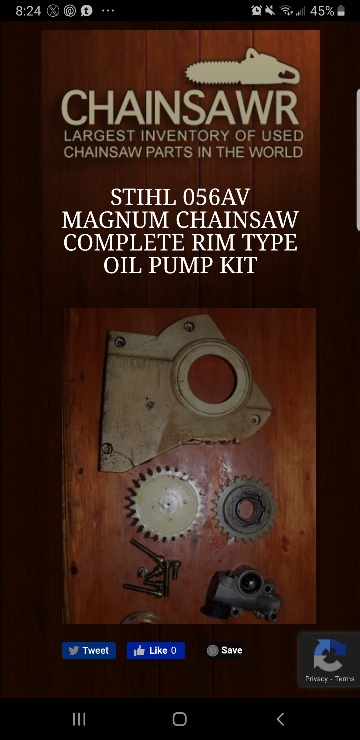

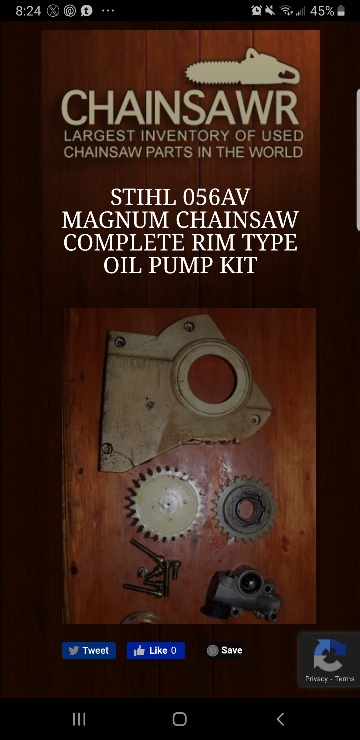

The all important thrust washer is indeed missing (at least in the pic) and that early spur gear's pin hole goes all the way through the gear allowing it to rub directly against the oil seal in the absence of the washer. Bad. Later spur gears were molded differently to minimize that possibility, but continued wear still allowed the pin to eventually protrude. That washer must be present. 0000 958 1404 is the current and only active part number and is the larger 30mm washer. It is also a backorder item domestically. (I happen to be waiting for one myself.) May be an available item for you regionally or could be scavenged from a later 1115 series parts saw.

The correct spur gear depends entirely on which bearing and seal are installed. As previously mentioned, there were several variants and all could be made to function to some degree or another, but the correct components are required as a complete assembly from the thrust washer on out to the clutch drum for reliable operation. As pointed out, that spur gear would appear to be a perfect example of the wrong part being applied and why replacing parts "like for like" on these particular saws isn't necessarily the most reliable way to ensure the correct parts are being used as replacements.

1115 007 1006 is the part number currently listed for the spur gear -- and not necessarily the correct one for your saw.. Take a pic of the bearing and seal as well as the backside of the spur gear and the cover. That will help us narrow it down for you.

It’s an aussi saw, will it still be useful?The washer was used on all variants. Also, post the serial number of the saw.

Ok great! So someone pinched it off this saw originally? Unless they never put it back on after taking it apart to check why it wasn’t oiling?Yes, your OP gear is good to go with the 30 mm OD washer!

Thanks mate I have the 045 ipl but not the updates, I’ll grab them from Ray as advisedYou need to download an 045 IPL.

That said, I’ve never found an 045 IPL with your old 031 type oil pump shown in it though...

Also need to go to the “Beg for manuals” thread & ask Mr Ray Benson for the 045 & 056 tech bulletins for the latest upgrades, there’s a lot of information to catch up on.

Good luck with the restoration.

Enter your email address to join: