wigglesworth

Booned

ass chain

What exactly is that? Are they hard to file?

ass chain

If she held pressure like you said it doesn't have a leak. I know a few people that had 088/880's that scuffed the piston and cylinder like yours. I think it's a combination of a few things, not just one big issue, like an air leak. Tuned lean, tight cold bore, bad fuel/oil, then running the saw with a dull ass chain. All of these things will make a new $1,600 880 worth $650 in a hurry.

If she held pressure like you said it doesn't have a leak. I know a few people that had 088/880's that scuffed the piston and cylinder like yours. I think it's a combination of a few things, not just one big issue, like an air leak. Tuned lean, tight cold bore, bad fuel/oil, then running the saw with a dull ass chain. All of these things will make a new $1,600 880 worth $650 in a hurry.

What exactly is that? Are they hard to file?

Ahh cool thanks for the link, I was looking all over for that info. Ok I will play around with it tonight and let you guys know how it goes.

The limiter caps were not on the saw when i got it (possible evidence of why the saw went bad in the first place) so I was a little unsure how to get back to the factory settings, all the carbs i have played around with in the past have only turned around once or 3/4 times or whatever. But hey thats why I asked the experts, thanks guys.

Also, my spark screen is pretty clean. Its sitting in my tool box right now, the saw wont run right with or without it. I will put it back in once I get the saw running before I put it to work though.

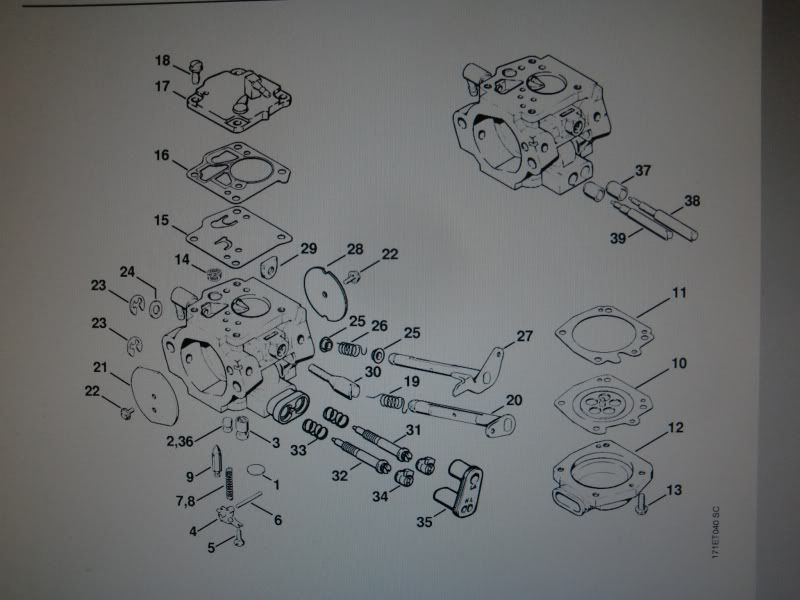

One last thing: on the top of my carb there is a fine gold colored screen, a thin, black rubber piece that matches the gold colored screen, and then a rubber gasket that matches the top plate that sits on top of it. I was originally missing the thin rubber piece but it came in the carb kit I ordered so I put it in. The service manual that I found doesn't include either the gold screen or the thin rubber thing. It says only two pieces go in between the top plate and the carb and i have 3 in between them. Does anyone know what I'm talking about? Here is a picture for reference , that is exactly what the carburetor looked like when I took it apart the first time, since then i have added a rubber piece that matches the gold screen piece between the [brand new] gasket and screen.

Ugh, I still have not been able to get this thing to run.

- I pressure and vac tested and could not find any leaks.

- I replaced the piston and fixed up the cylinder, tested it to 155 Psi today

- Completely rebuilt the carb

- Re gapped the coil

- New spark plug, new gas new fuel filter, new fuel cap, cleaned gas tank vent

- Checked all hoses, muffler, gaskets, air filter.

I put on a 36" brand new bar and chain, the saw starts up and runs, and with a little carb adjustment it revs normally but still will not return to idle no matter how I mess with the carb. I have had the screws in every configuration i could think of from maxed out lean too both at 2.5 turns CCW the saw just wont idle.

Knowing what I have done so far, what would you check next/recheck.

Enter your email address to join: