Lakeside53

Stihl Wrenching

Nice work!

Nice work!

Post away Will. No tools here yet.

Guess thats why I don't own a lathe.

Guess thats why I don't own a lathe.Thats one fine looking piece of machinery Will.:msp_thumbup: Unfortunatly, I don't have a clue what it is, or what its used for.Guess thats why I don't own a lathe.

It has been interesting though, trying to follow this thread. Lots of great help & advice from the experts. Kind curious how quickly Brad gets up to speed with this venture. I'm sure it won't be long, with all the help here, and from an excellent mentor or tutoring from the big guy in black.:msp_thumbsup: living close by.

Gregg,

Also finished my boring bar this evening.

Drilled and tapped the two holes for the Socket Head Cap Screws, and De-burred the slot.

OK, I said SHCS but unless recessed use set screws, or maybe you call them "grub screws" on your side of the border! You'll get a lot less swarf trapped and it will aid visability and clearance.

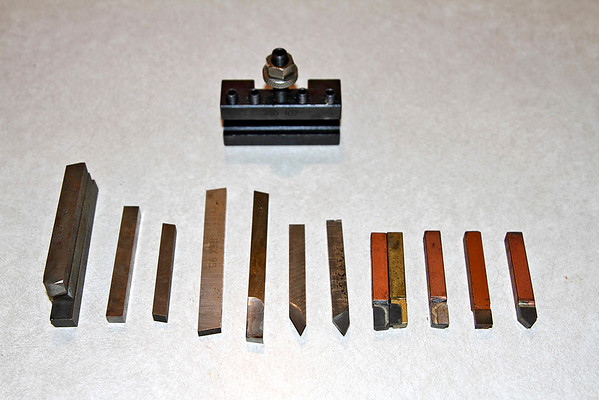

I got a nice assortment of tooling in the mail today. Thank you very much! It's time to start making some chips now.

I got a nice assortment of tooling in the mail today. Thank you very much! It's time to start making some chips now.

Wow, that thing is HUGE!

Different strokes.

I always leave the compound bottomed out and dial with the carriage for the amount I want.

Yes so do I. I was just saying if he wanted to do it that way. I have a indicator on the carriage so its much more accurate then the dial. I want to do away with the compound and just mount directly to the carriage so its much more rigid. I'd have to use the compound for some things, but most of the time it would be better without.

Yeah I got that from your post.

I was talking to B Rad. Just haven't found a 2x4 big enough to make him listen. LOL

Timing just made it sound that way.

Enter your email address to join: