cluelessmontana

ArboristSite Lurker

- Joined

- Mar 10, 2023

- Messages

- 20

- Reaction score

- 2

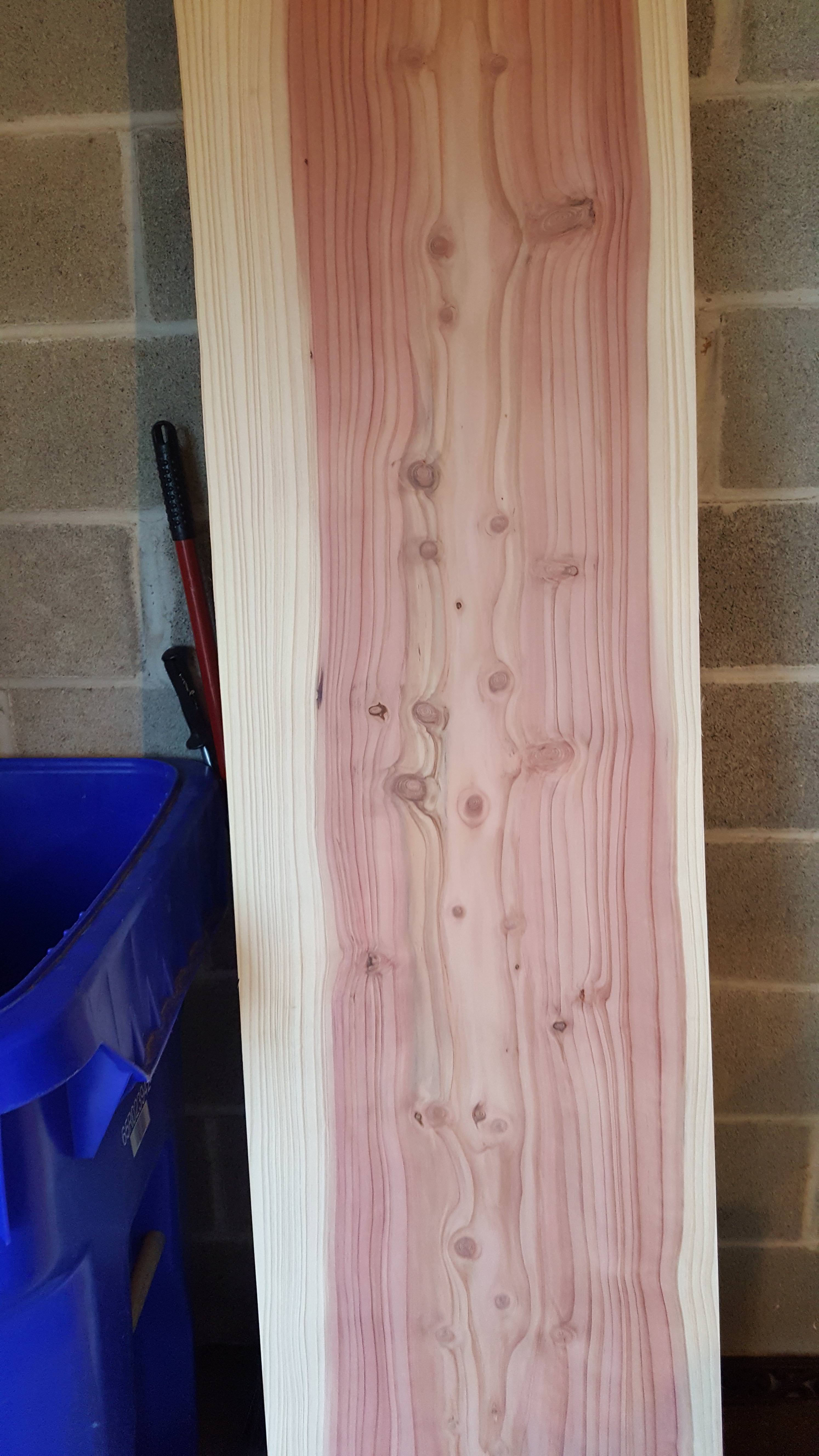

https://dl3.pushbulletusercontent.com/OvtRcQsL26tyWuclaROyqzYctPaoi8jX/20230514_203724.jpg

when I mill small logs with my ms180, i get no scoring, even with a normal non-milling chain (it uses 3/8 lo pro)

When I mill with my 460 rancher or 555, i get this scoring if i use a normal non-milling chain, but only sometimes as seen in the picture. If I use a chain ground to 10-15 degrees, then I usually get very little scoring. I'm just curious why it happens only with the bigger saws and how to prevent it.

when I mill small logs with my ms180, i get no scoring, even with a normal non-milling chain (it uses 3/8 lo pro)

When I mill with my 460 rancher or 555, i get this scoring if i use a normal non-milling chain, but only sometimes as seen in the picture. If I use a chain ground to 10-15 degrees, then I usually get very little scoring. I'm just curious why it happens only with the bigger saws and how to prevent it.