I started this thread so amateurs like myself might have a better understanding of the bar oil leaking 346xp (the blind leading the blind?). My 346xp performs like a champ and we all know it's place amongst the great saws but when it drains the oil tank after shut down there must be a problem. I found where mine is leaking from and hope this helps others find their leak (if they want to).

Sitting here for 12 hours. May be normal to some but I'm going to try and at least slow it up a bit.

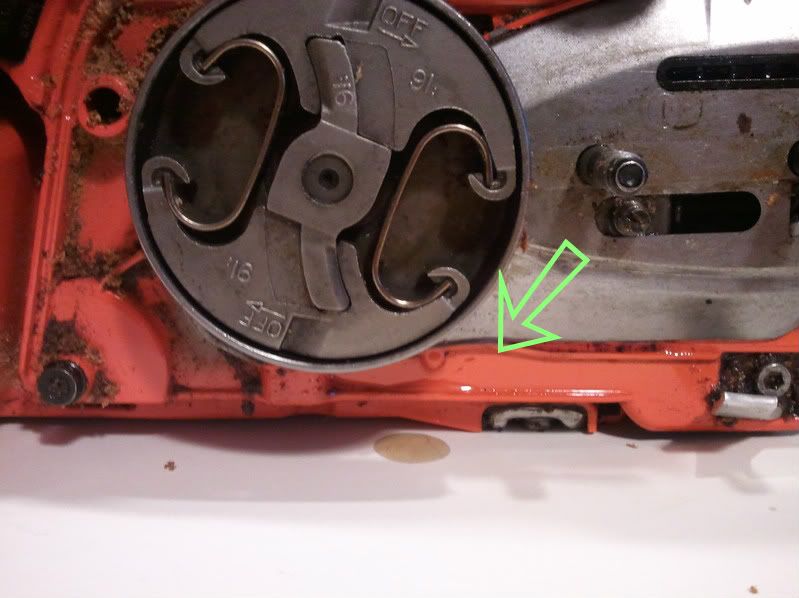

Green arrow points to where the oil is pooling before dripping out.

Removed the clutch.

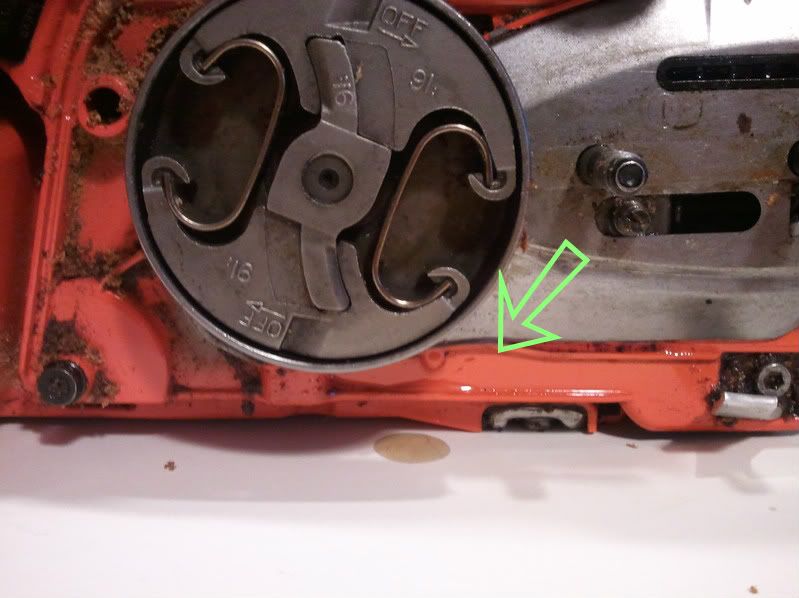

Down to where we can start seeing the origin of the leak. Green arrow points to where it seems to be oozing. The area where the yellow arrow points to is completely dry, so oil is not leaking down from where the oil tube meets the bar.

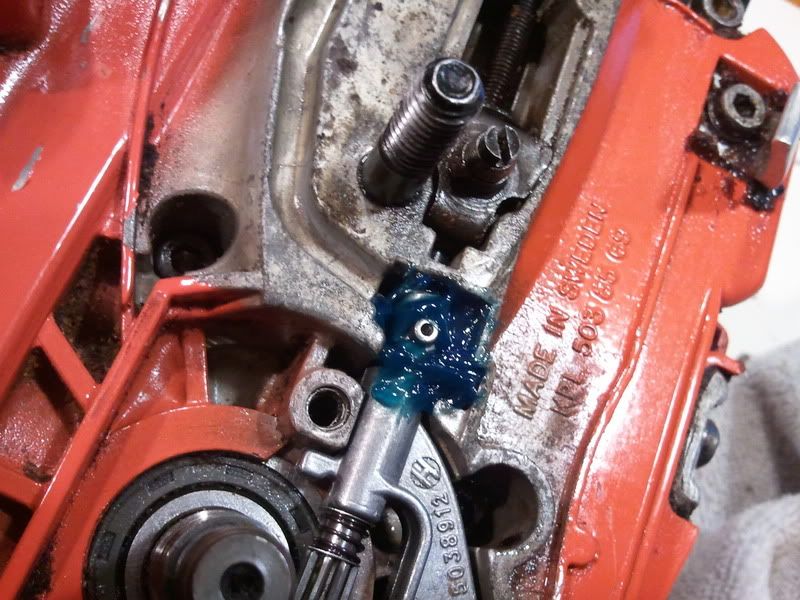

Pulled the tube that runs from the oil pump up to the bar. The Green arrow points to a nipple on the pump that the oil tube seats to. This is a possible leak source.

Removed the oil pump. Here the green arrow points to a rubber saddle that the oil pump seats into with the same type of nipple on the outer side. Same possible leak source. The rubber saddle itself seats into the oil tank which could be another possible leak source.

Sitting here for 12 hours. May be normal to some but I'm going to try and at least slow it up a bit.

Green arrow points to where the oil is pooling before dripping out.

Removed the clutch.

Down to where we can start seeing the origin of the leak. Green arrow points to where it seems to be oozing. The area where the yellow arrow points to is completely dry, so oil is not leaking down from where the oil tube meets the bar.

Pulled the tube that runs from the oil pump up to the bar. The Green arrow points to a nipple on the pump that the oil tube seats to. This is a possible leak source.

Removed the oil pump. Here the green arrow points to a rubber saddle that the oil pump seats into with the same type of nipple on the outer side. Same possible leak source. The rubber saddle itself seats into the oil tank which could be another possible leak source.

Last edited: