ok so I have been using chainsaws for years and have recently gottne back into tree removal. I used to do it in HS and college. I have a moded 044 and have been using it to cit down the spar. I have been 60' up with it and had no problems at all with a 20" bar. rips right thru the pine. But today My buddy was working with me. I saw him using my 044 after i put a 28" bar on it to buck up the trunk and he kept binding it. So after awhile I went over there and had the same problem. I know the saw has plenty of power to rip thru a 22" pine laying on the ground but it kept binding, and the dogs are extremely hot. What Am I overlooking I have never had this problem before. I am not running a skip tooth chain. but the bar and chain are brand new.???? cuts are streight. how is a little pine binding my 044 that easy

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

044 binding in 20" pine

- Thread starter adam0321

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

dingeryote

Blueberry Baron

Check and see if the thing is oiling adequately.

Pine gorp in the passage maybe?

Hot Dawgs means a Hot bar=friction somewhere normally.

Take a gander at the clutch while you're in there.

If your luck is like mine, it might be a bit toasty from the abuse.

Stay safe!

Dingeryote

Pine gorp in the passage maybe?

Hot Dawgs means a Hot bar=friction somewhere normally.

Take a gander at the clutch while you're in there.

If your luck is like mine, it might be a bit toasty from the abuse.

Stay safe!

Dingeryote

dingeryote

Blueberry Baron

its going thru oil just fine. about 1 oil fill to every 3 gas fills but i will check it. I know I have to much friction somewhere

Ummmm.......

That's a typo right? 1 tank of oil for every 3 fuel fills?

Stay safe!

Dingeryote

dingeryote

Blueberry Baron

always used husky before. and never a saw this big or moded the way it is. should i be looking at a 1/1 retio?

Yep. 1/1 is about right.

When ya get it adjusted, start the saw and point the tip(Within a couple inches) at some bare concrete or clean piece of newspaper and rev it up a couple times. OIl should fling and be obvious on the paper.

On most saws, I just turn the oiler all the way up to start with untill I get a feel for them. It's better to have too much oil than not enough.

Pine has lotsa sappy gooey gunk to clog up a bar groove, if there ain't enough oil keeping the gorp suspended.

Good luck to ya!

Stay safe!

Dingeryote

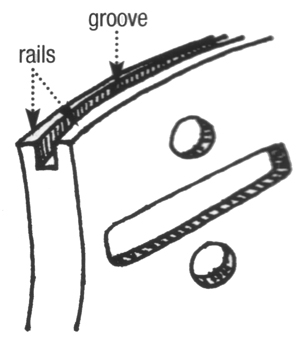

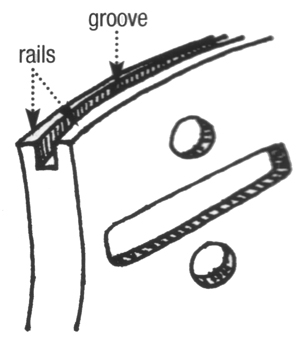

Check the rails on your bar. Running the chain too tight will cause them to wear. You can feel a slight ridge on the outside of the bar. That makes the bar just a little wider and will bind up in the cut. Just file it off.

I'm from back in the day of thumb pumps and if the men didn't empty a tank of oil per tank of fuel they got a good talkin to. One oil to 3 fuel you're toasting the bar, Joe.

thanks guys I really appreciate it. I will be adjusting the oiler today and giving it another try. I know for a fac I did not have the chain to loose. Sounds like it is deff the oiler. I am just glad to get advice on this forum with out the "well you are not a pro like me and probaly have no business running a saw, and can never do what I do or be as good as me because I am a pro so.....just sell the saw and find another line of work". obviously not everyones opinion on this site but damn there are some PERFECT sob on here

rwbinbc

ArboristSite Operative

It sound to Me like someone bent Your bar, Check the bar on a straight egde and flip it over from side to side and look for a gap. Just My guess at it. The saw will start the cut fine but once it is in far enough it starts to bind from the twist in the cut.

My 2 cent I'm bad for bending bars on My 394xp using if to flip the blocks off the trunk.....

My 2 cent I'm bad for bending bars on My 394xp using if to flip the blocks off the trunk.....

well I checked the oiler today. it was all the way in so I backed it out almost all the way and it still got the bar extremely hot and bound the bar in the wood once I was about 3" into it. I checked the oil and I am still only going thru about 1-3 gas to oil. So I think I am going to turn it in to have the oiler checked. I know it has to be gunked up with a #### load of sap. I put the 20" bar back on and it riped right thru the logs. so that makes me think its the bar or chain. but the bar looks streight???? any help

BigE

ArboristSite Operative

Are you by chance running 058 or 063 chain in a 050 bar? That would bind it up nicely.

Make sure you are cleaning your bar groove

also on oposite sides of the bar you will see the oiler holes that feed the grove. Small holes (smaller then the round adjuster holes in picture) those holes clog up a lot. Ensure when you clean the grove you clean them holes out too. Take the bar off and the spacer under it and make sure thats channel is free of debris.

also on oposite sides of the bar you will see the oiler holes that feed the grove. Small holes (smaller then the round adjuster holes in picture) those holes clog up a lot. Ensure when you clean the grove you clean them holes out too. Take the bar off and the spacer under it and make sure thats channel is free of debris.

Last edited:

rwbinbc

ArboristSite Operative

Sounds like a bent bar, Right by the power head.

BigE

ArboristSite Operative

3-1 fuel / oil ratio - sure as heck sounds like the oil hole on the bar is plugged up, then. Does flipping the bar over make any difference?

NeoTree

ArboristSite Guru

Sorry for the hijack, I got a question too .I bent my 36" stihl es bar just a tad yesterday in a horrible pinch. Sitting on a flat table it has about a 1/32 to 1/16 of an inch high off the table, seems to be more bent by the powerhead. The saw was binding when burried, especially when i had it on the dawgs. Think it's bent enough to really make a difference?

Just bend it back.

1. Get a sturdy vise and a nice mallet.

2. Lay the bar across the open jaws of the vise, lining up the sharpest bend pointing up, right between the jaws.

3. Pound downward only as heavy as you need to straighten the bar. It takes surprisingly little force for a chainsaw bar. Be careful about where you place it on the jaw, as this is the only place it will bend.

4. Reposition as needed until you get it right.

I watched a guy at a spring rebuilding facility re-curve truck springs using this method. I've been using this method ever since for all kinds of metal.

1. Get a sturdy vise and a nice mallet.

2. Lay the bar across the open jaws of the vise, lining up the sharpest bend pointing up, right between the jaws.

3. Pound downward only as heavy as you need to straighten the bar. It takes surprisingly little force for a chainsaw bar. Be careful about where you place it on the jaw, as this is the only place it will bend.

4. Reposition as needed until you get it right.

I watched a guy at a spring rebuilding facility re-curve truck springs using this method. I've been using this method ever since for all kinds of metal.

Similar threads

- Replies

- 17

- Views

- 2K