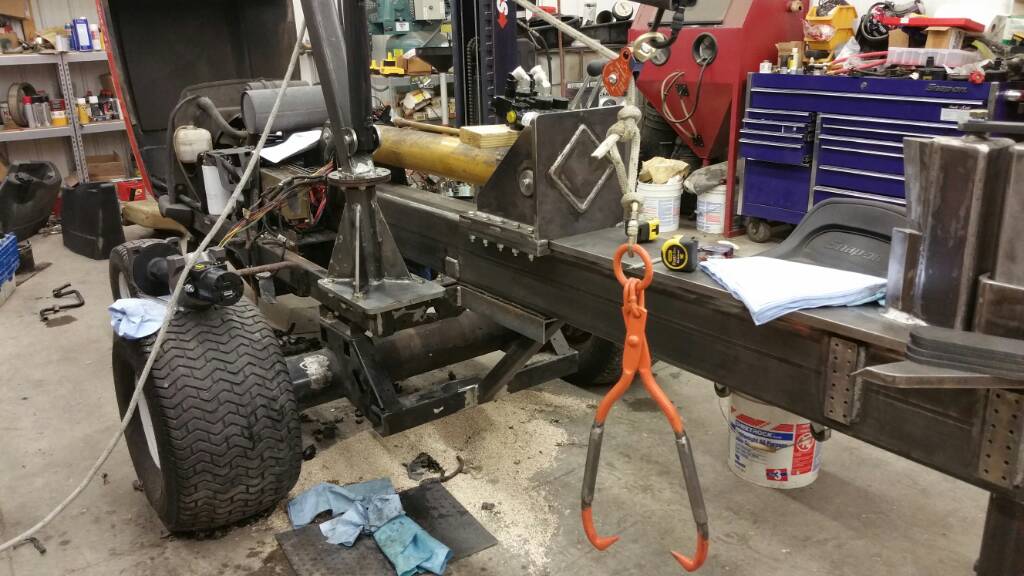

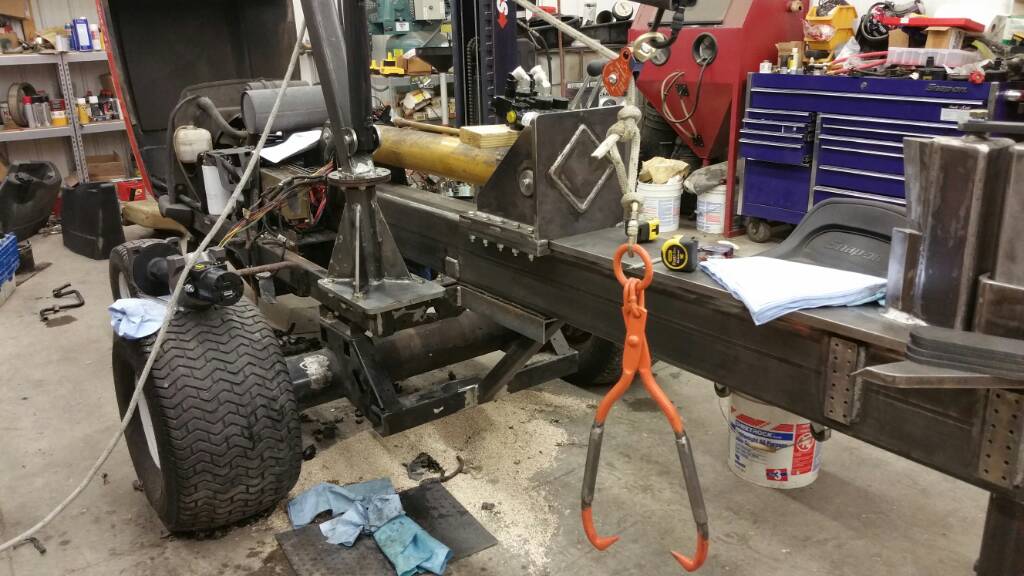

Winch mount made.

Was that a calculated 2 second return stroke? I only ask, as everything I've calculated was always a tad slower in actuality. My return stroke was to be 2 seconds.....but I think I know a couple factors in why it's a little slower. I do like the quickness of mine, it's out of the way so I can grab the next piece off the log lift. Might be different in your operation. A quick return might even make the auto valve seem like you don't need it, since it will return very quickly. Just saying. Can't wait to see it done or a test run!Was thinking I should slow down the return stroke of the large shaft cylinder. From looking at the flow of auto cycle valve I could put a check valve and flow divider on the D port of the auto cycle valve. 2.? Seconds is pretty fast for 30 inch stroke. Plus slow down the amount of oil going to the dump valve.

Seems backwards wanting to slow the splitter down.

not necessarily....depends on the splitter....Was thinking I should slow down the return stroke of the large shaft cylinder. From looking at the flow of auto cycle valve I could put a check valve and flow divider on the D port of the auto cycle valve. 2.? Seconds is pretty fast for 30 inch stroke. Plus slow down the amount of oil going to the dump valve.

Seems backwards wanting to slow the splitter down.

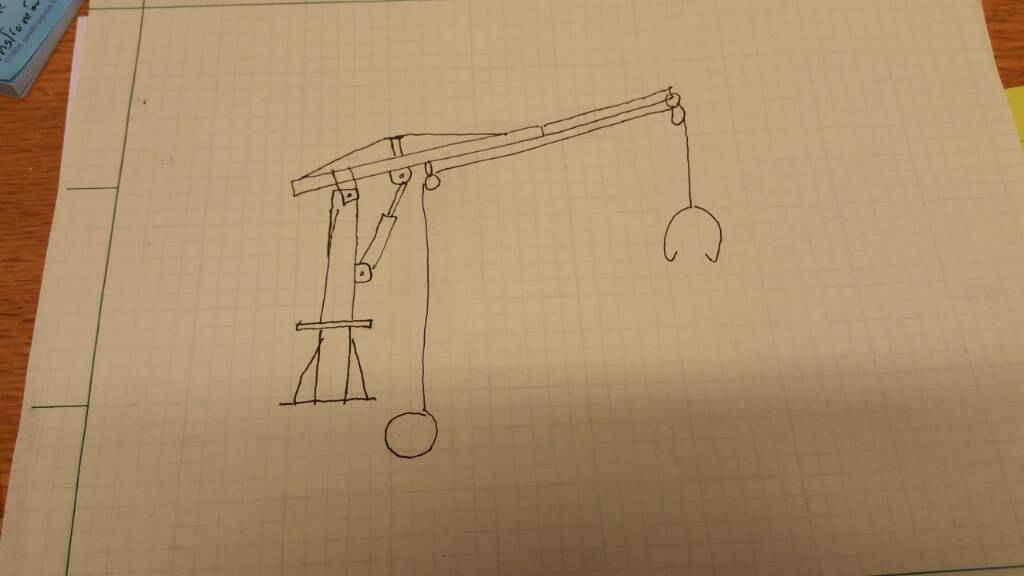

Down by the tire it will affect your swivel, and believe me u swivel it alot.

Enter your email address to join: