Has anyone ever had issues with the case gasket leaking on these kits? used mine last weekend but after a short break it started up and smoked badly... sure enough oil was weeping into the crankcase.

I split the cases, couldn't see anything wrong. The mating surfaces looked ok and flat so cleaned them up and put a new gasket in this time smeared each side with 1184. Admittedly I didn't wait long enough for the 1184 to set up totally but a low pressure test shows an air leak into the oil tank (bubbles showing at the end of the oil feed pipe).

It's a bit baffling. Before I split it down again I'll leave it overnight with full tank of bar oil in just to see if the gasket swells a little and seals but I'm not holding my breath...

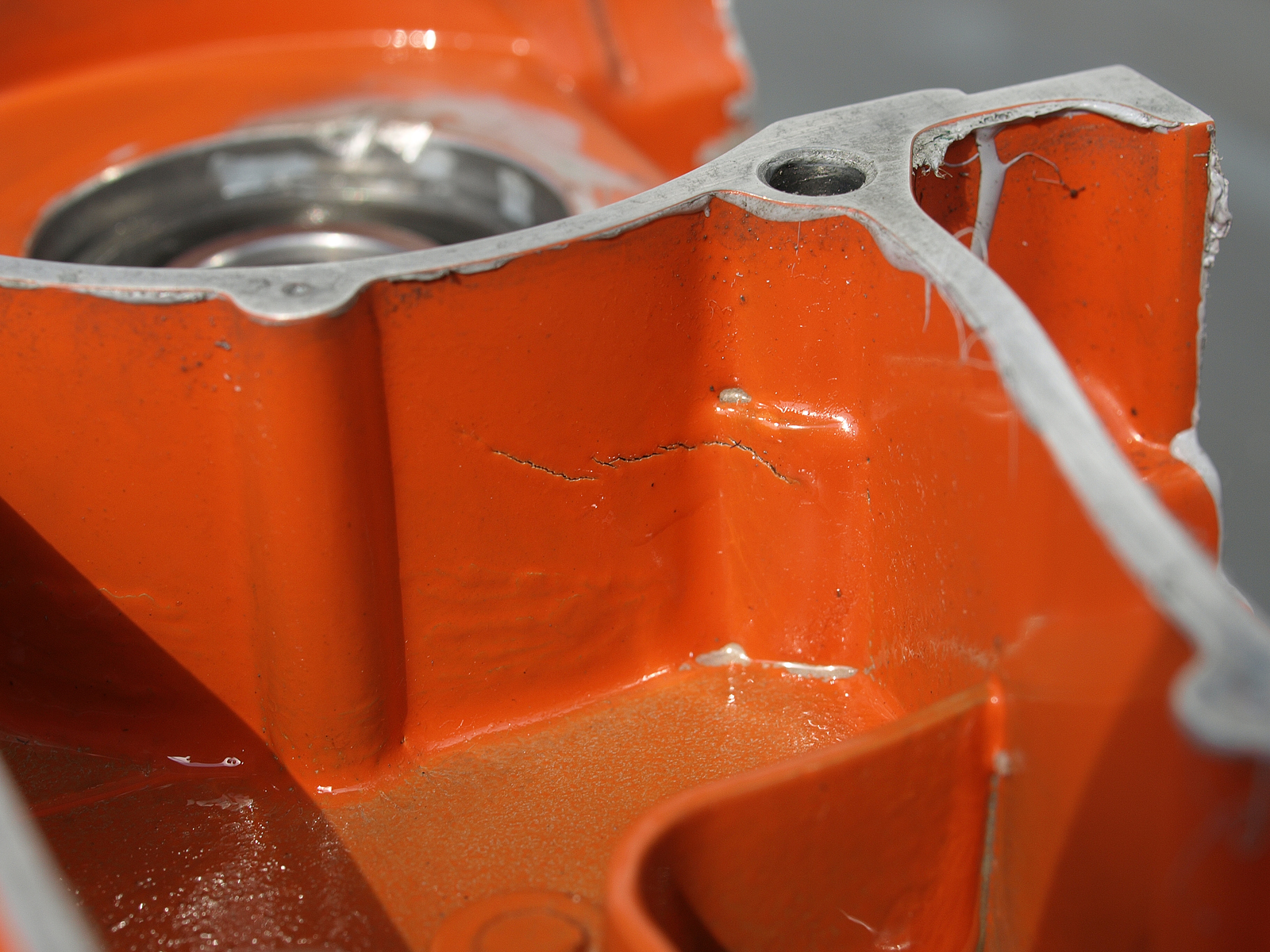

Scrap that idea I couldn't leave it, knowing I might not get a chance to look at it again for a while, I decided to split it again. This time I rushed less, had a real good look and got to the bottom of it... in my haste the first time and convinced it could only really be the case gasket I overlooked the real problem....

That definitely wasn't there when I assembled it. It looks like the powder coat was covering it up and sealed it hence why it initially passed a pressure / vac test but with a bit of heat and vibration the powder coat let go causing the leak

.

I've messaged Huztl hopefully they will get me sorted. I'll keep you posted...