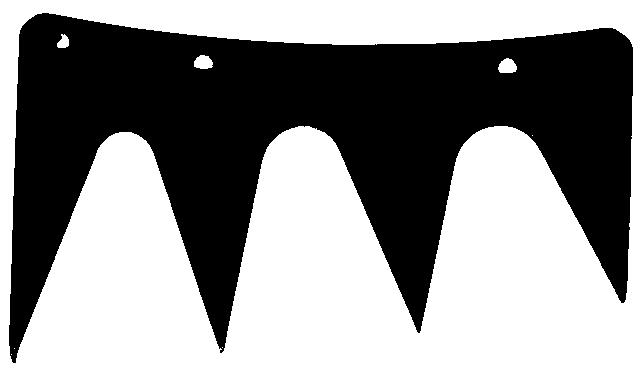

The saw was set-up to run .404 chisel chain in most of NA, especially the PNW. Some even had spur drums which absolutely confounds me on a saw of that size. Your problem is gonna be the mount spacing which is 10mm and those bars haven't been made in quite some time. Sometimes, the large mount Husky bars will fit because they get sloppy with the machining. But you can't just buy a large mount Husky bar and expect it to work. Requires just a bit of milling on most. I did that with a Carlton bar once and it wasn't fun. Had to open up the rail a bit too.

I don't know what your market is downunder, but best case scenario is to find a decent used bar that was originally the J'reds 10mm mount style. Second choice would be the large mount Husky which is supposed to be 9.5mm. The saw was also made to power up with a .063 gauge bar. I guess it could have been set-up with that bar pictured, but there were no shortage of smaller saws that would outrun it in small timber, not mention lugging around all that extra heft in smaller scale. I notice it doesn't have the full-wrap handle...you never see one around here(PNW) without one. If you're fallin' big scale without a full-wrap, you're working against yourself. Doesn't sound like you can even do that downunder anymore in a lot of places.

Don't put too much credence on chain brakes, as I've never had a saw with one yet.....it was mostly an option in the older saws at first. I think they are good thing for the occasional wood cutter and firewood gatherer, but if you're a pro they are a nuisance.

Kevin