walkerdogman85

ArboristSite Operative

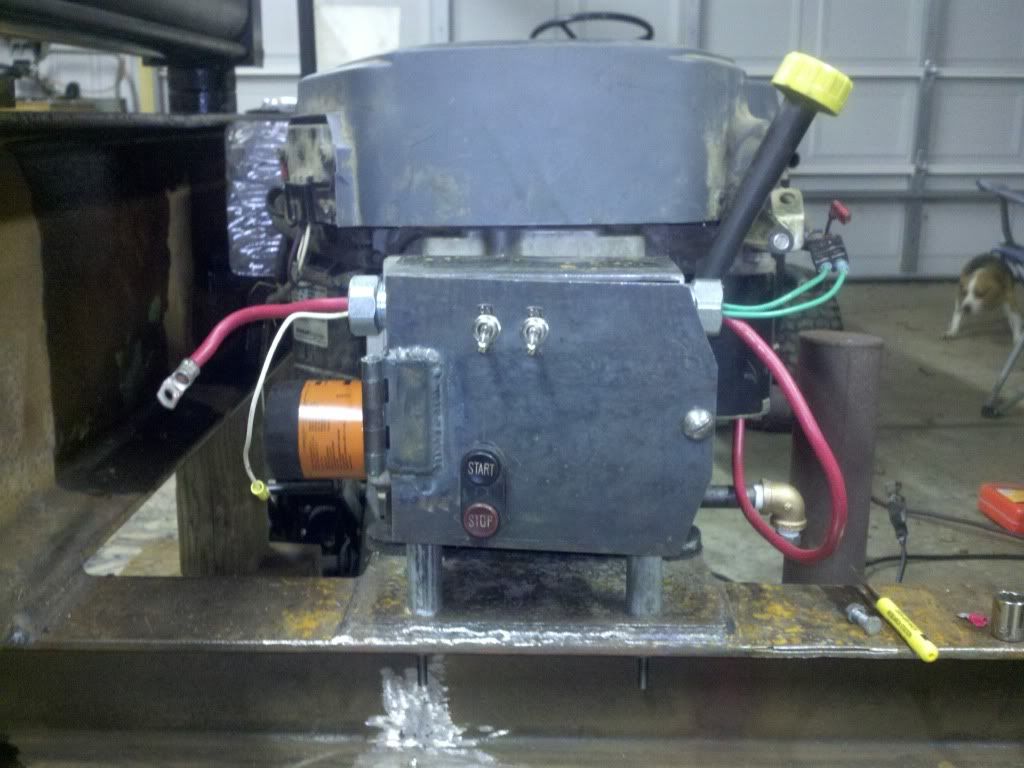

sorry but we have the pump mounted we just took it off in the pics to shim it dont have a pic of it on there but it is done real similar to yours we had to cut the motor shaft down i will try and post a pic tomorrow. just got in a hurry when i took the pics and posted them i really appreciate the suggestions and the comments. we will put your guys advice to use thank you

You won't feel "whole" until you do it.:msp_biggrin:

You won't feel "whole" until you do it.:msp_biggrin: