Opihi59

ArboristSite Operative

Sorry I haven't been here much lately, lotta extraneous stuff going on and the saws have all been happy......

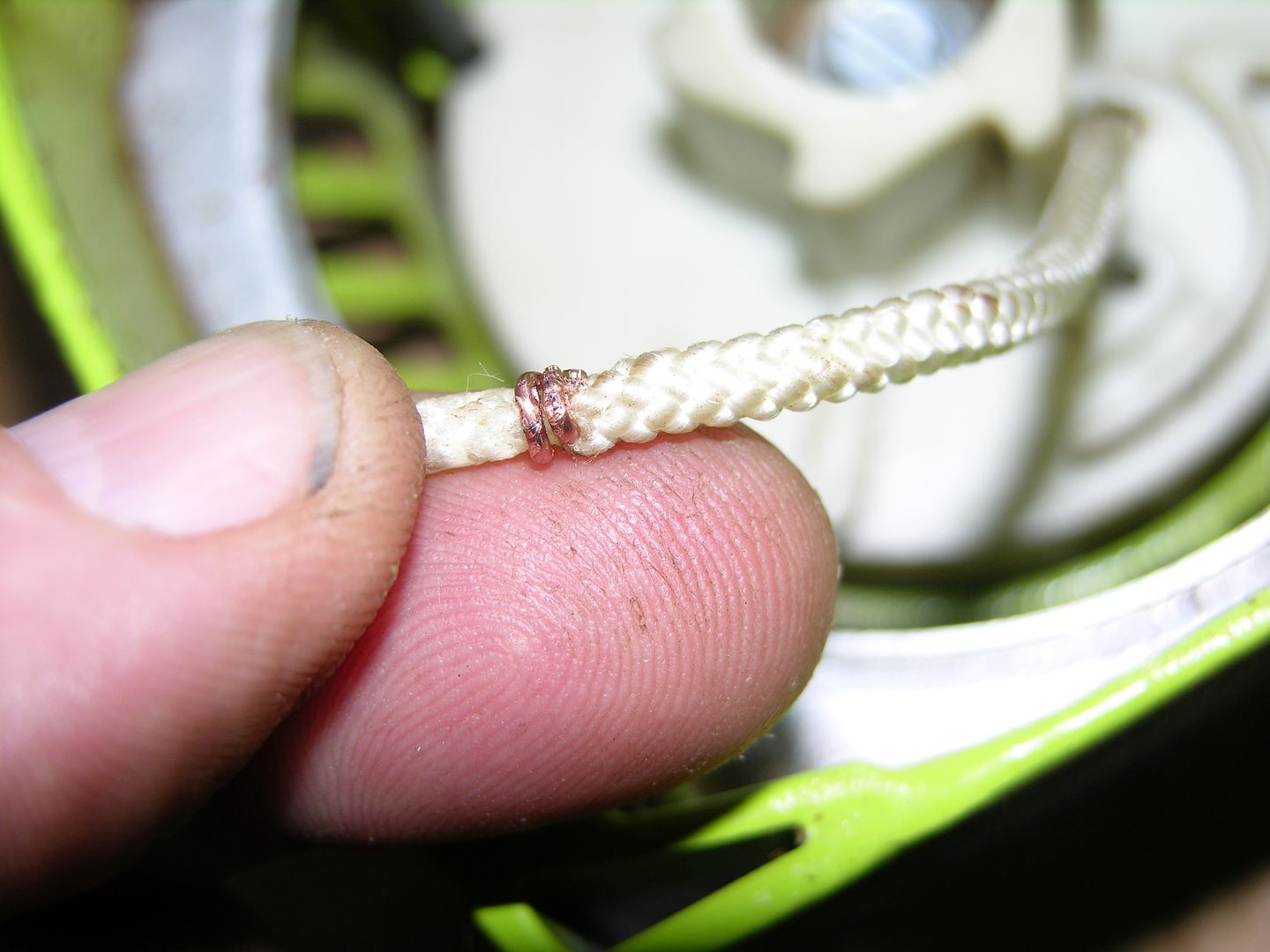

Until I decided to crank up my little Poulan treasure $5 garage sale find 2400 2.3 cube Woodmaster and ended up with saw in one hand, and starter cord (complete) in the other.

This little treasure:

So the story behind the saw is I rescued it, covered in filth, grime, bar lube/sawdust detritus, spiderwebs and the PO-previous owner-for 5 dead Presidents and I bolted before he could discover his mistake. On teardown and cleanup, I found it to be essentially new with visible factory machining still on the ring, and a pristine bore. It only needed new fuel lines, then as a bonus I rebuilt the carb.

Since I haven't been here for a while, I figured I'd share a thread on replacing the starter cord on this little gem. I lack the skills to be able to easily draw circles and arrows on my photos, so you'll have to bear with my vintage technique.

To start out, there are only a few screws to remove to pull off the starter housing. 4mm hex screws at the end of the orange string trimmer lines.

Slotted screwdriver style screw here at the end of the orange string:

And under the handle at the end of the 4mm allen key:

Once you get these off, the only thing holding the case half to the rest of the saw is the on/off, and I couldn't easily pull the wire, so I just undid the nut and left the toggle switch hanging on the rest of the saw. There are other screws you could remove; initially I pulled off the carb cover and carb plate, but it's not needed at all for disassembly and it only results in 5 more screws to lose.

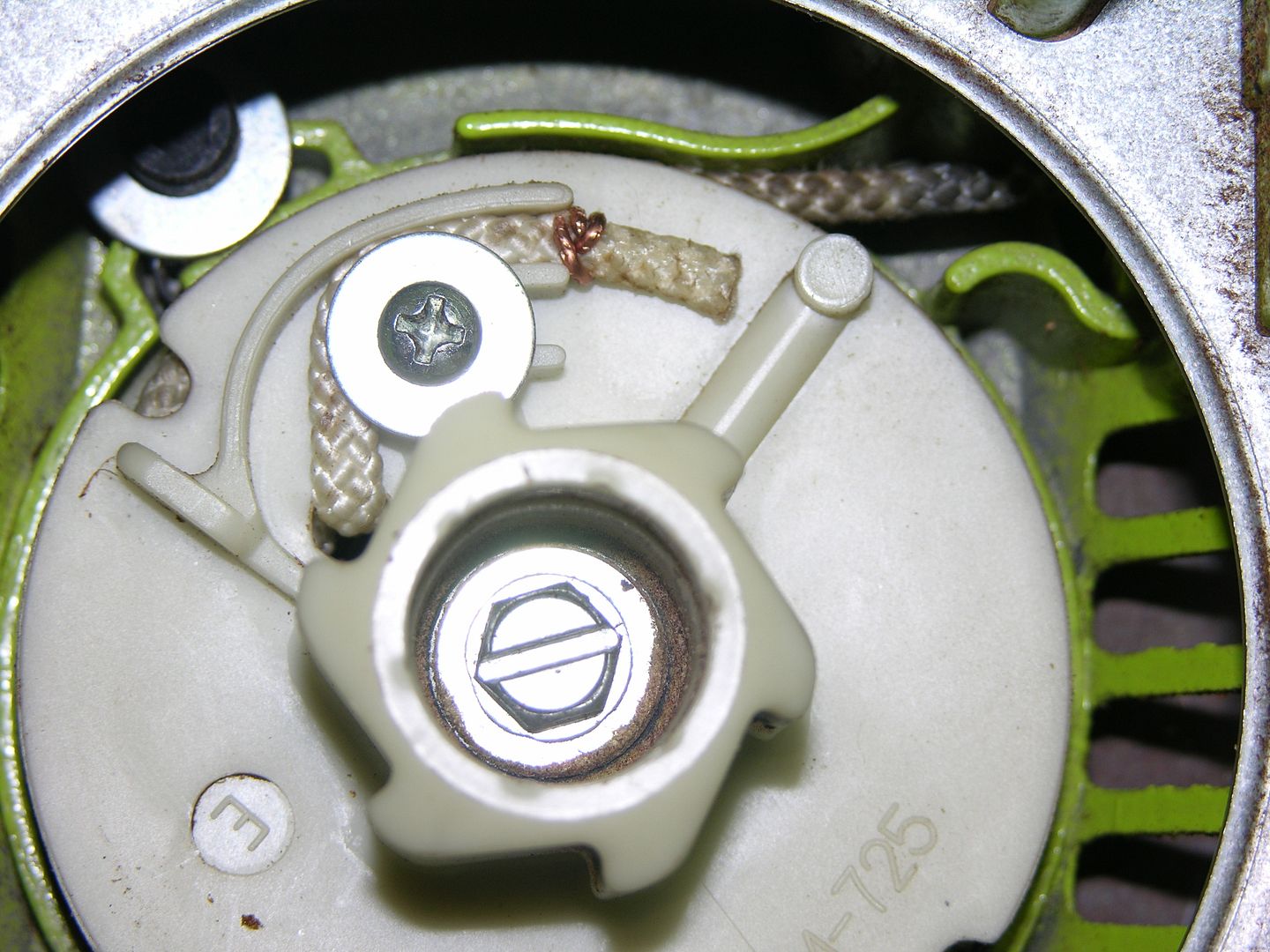

The starter pulley mechanism is plastic, and it turns out that the only thing holding the end of the cord to the pulley is a screw and washer in a clamping action which you can see at the 6 O'clock position on the photo.

Until I decided to crank up my little Poulan treasure $5 garage sale find 2400 2.3 cube Woodmaster and ended up with saw in one hand, and starter cord (complete) in the other.

This little treasure:

So the story behind the saw is I rescued it, covered in filth, grime, bar lube/sawdust detritus, spiderwebs and the PO-previous owner-for 5 dead Presidents and I bolted before he could discover his mistake. On teardown and cleanup, I found it to be essentially new with visible factory machining still on the ring, and a pristine bore. It only needed new fuel lines, then as a bonus I rebuilt the carb.

Since I haven't been here for a while, I figured I'd share a thread on replacing the starter cord on this little gem. I lack the skills to be able to easily draw circles and arrows on my photos, so you'll have to bear with my vintage technique.

To start out, there are only a few screws to remove to pull off the starter housing. 4mm hex screws at the end of the orange string trimmer lines.

Slotted screwdriver style screw here at the end of the orange string:

And under the handle at the end of the 4mm allen key:

Once you get these off, the only thing holding the case half to the rest of the saw is the on/off, and I couldn't easily pull the wire, so I just undid the nut and left the toggle switch hanging on the rest of the saw. There are other screws you could remove; initially I pulled off the carb cover and carb plate, but it's not needed at all for disassembly and it only results in 5 more screws to lose.

The starter pulley mechanism is plastic, and it turns out that the only thing holding the end of the cord to the pulley is a screw and washer in a clamping action which you can see at the 6 O'clock position on the photo.

:yoyo:

:yoyo: