jimdad07

Addicted to ArboristSite

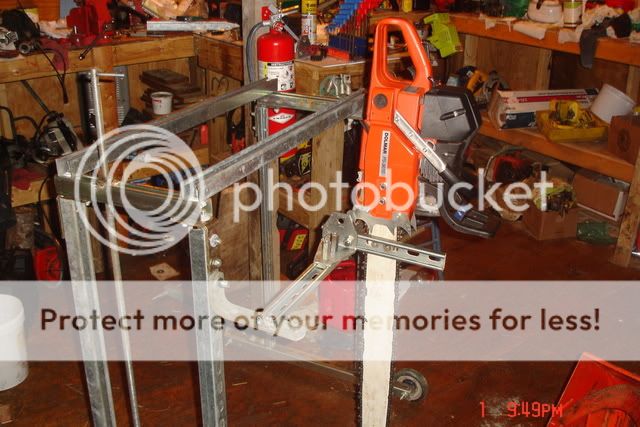

Hi guys. I have had a few of you want to see closeups of how I made the carriage mill work. It is very simple and please feel free to poke at the poor welding. The 110v mig I was using did not like to weld the galvinized unistrut very well and they did not turn out very well. I also made another bracket for the saw so that I can edge the logs for making square cants without having to turn the logs over. Here you go, there are a few pics.

1: This is a closeup of the vertical adjustment, all it is is a nut and a rod coupling welded to each side of the bracket that holds the saw so that when I turn the handle on the thread rod at the top it will move the bracket up and down.

2: This is a closeup of the piece conduit that holds the bottom of the rod in place so that it doesn't move while in use. It is just sitting lose in it.

More to follow in a moment.

1: This is a closeup of the vertical adjustment, all it is is a nut and a rod coupling welded to each side of the bracket that holds the saw so that when I turn the handle on the thread rod at the top it will move the bracket up and down.

2: This is a closeup of the piece conduit that holds the bottom of the rod in place so that it doesn't move while in use. It is just sitting lose in it.

More to follow in a moment.