Khntr85

Addicted to ArboristSite

Very Interesting....35 top-plate....would like to run that and see how it worked....of course some say the old saws had more torque that the higher RPM saws of today...

Very Interesting....35 top-plate....would like to run that and see how it worked....of course some say the old saws had more torque that the higher RPM saws of today...

Yes that's twice as much as .404 chain. What the heck. .030 makes my 77cc burn some serious fuel . Must be for that twin cylinder chainsaw that was posted while back lol. [emoji3][emoji106]Wow .060 on rakers that would hell on a chain and a saw!

Sent from my iPhone using Tapatalk

Yes that's twice as much as .404 chain. What the heck. .030 makes my 77cc burn some serious fuel . Must be for that twin cylinder chainsaw that was posted while back lol. [emoji3][emoji106]

Woodblocker55

Sent from my LG-H900 using Tapatalk

Good idea!Another option is to have different chains optimized for different types of wood, or current conditions, and swap them out as needed. Kind of like a socket set.

What brand of grinder do you have....First sharpenings with new wheel. Outside to inside; 30* 60* no tilt. Ron

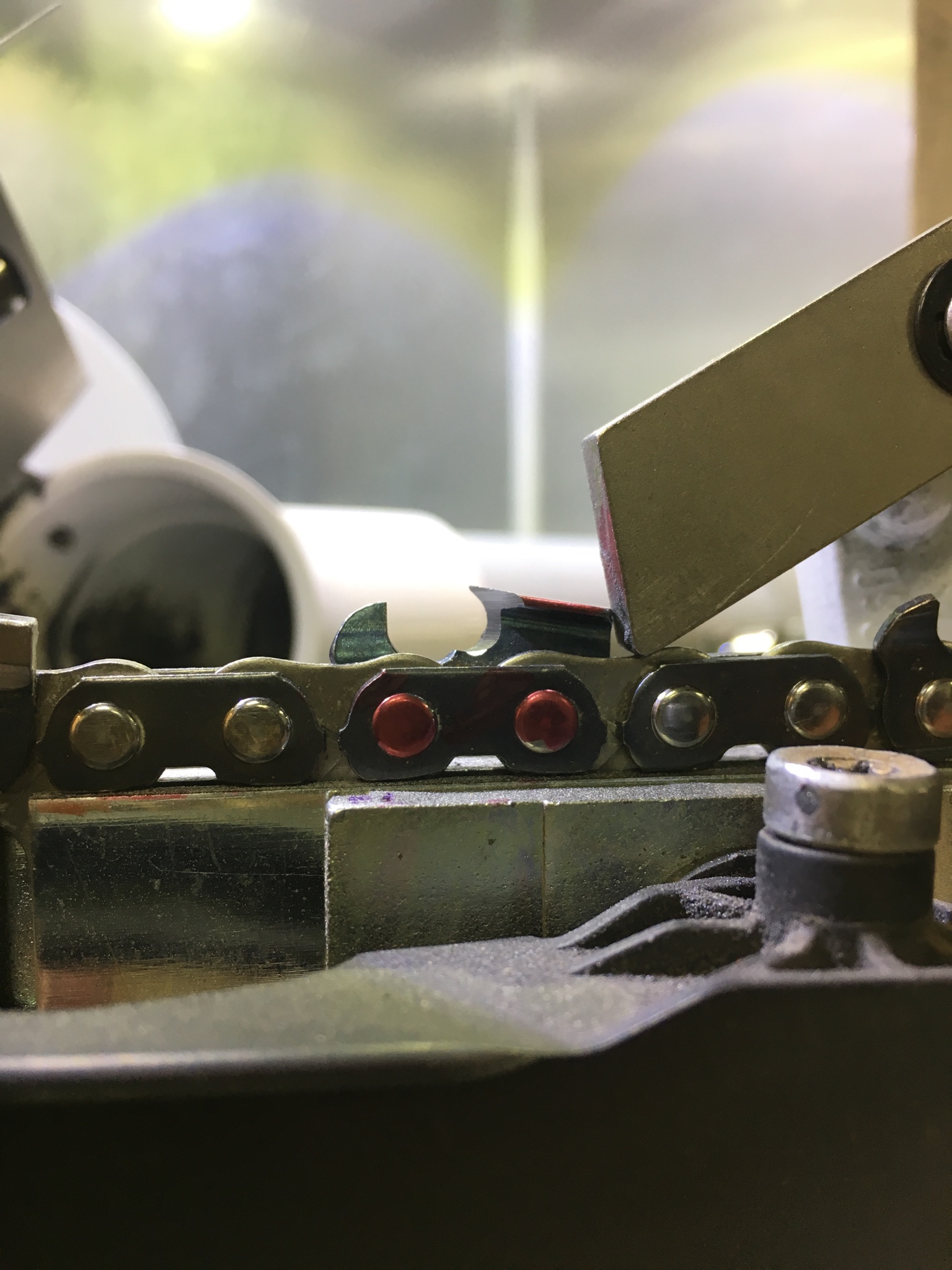

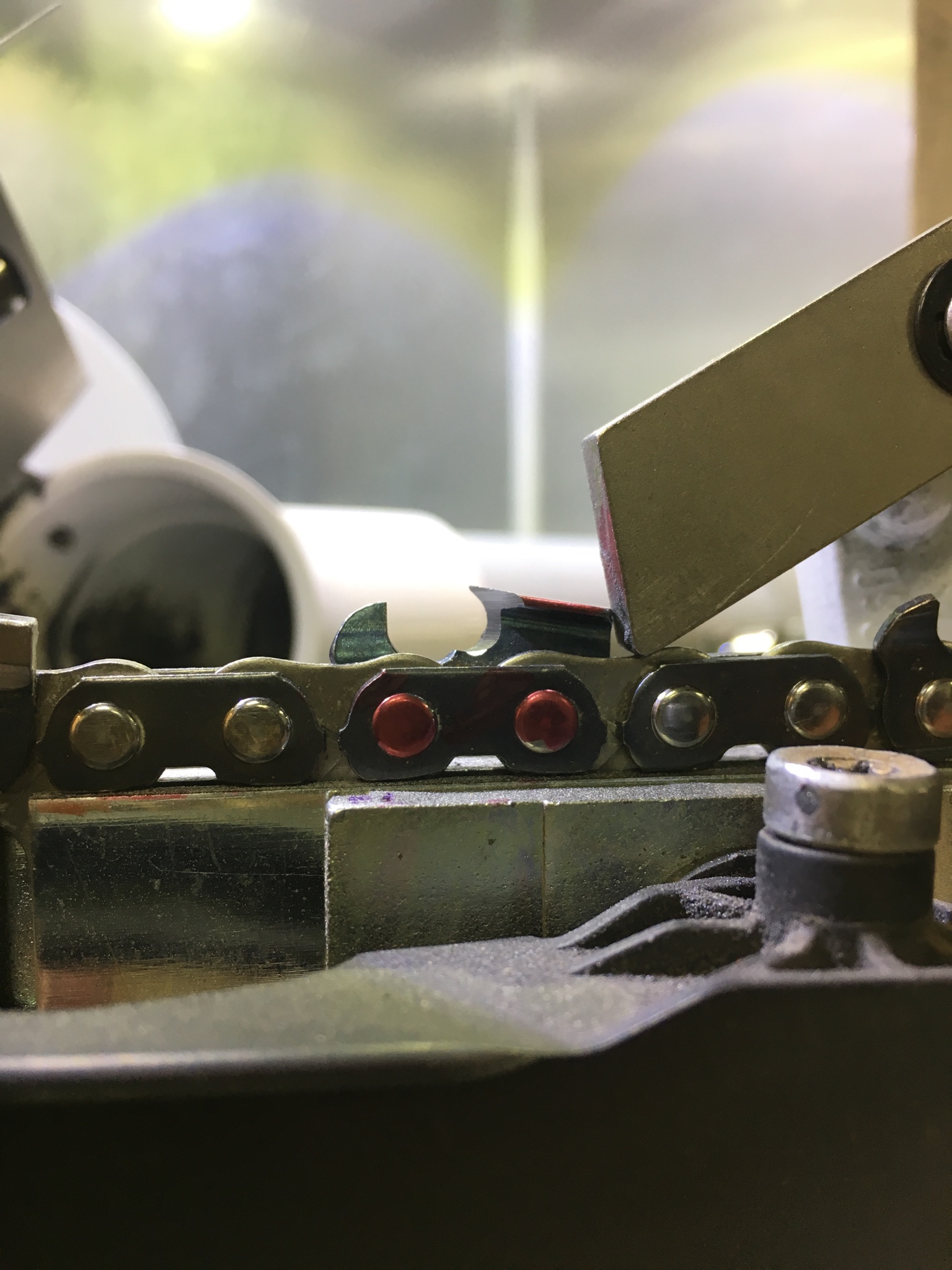

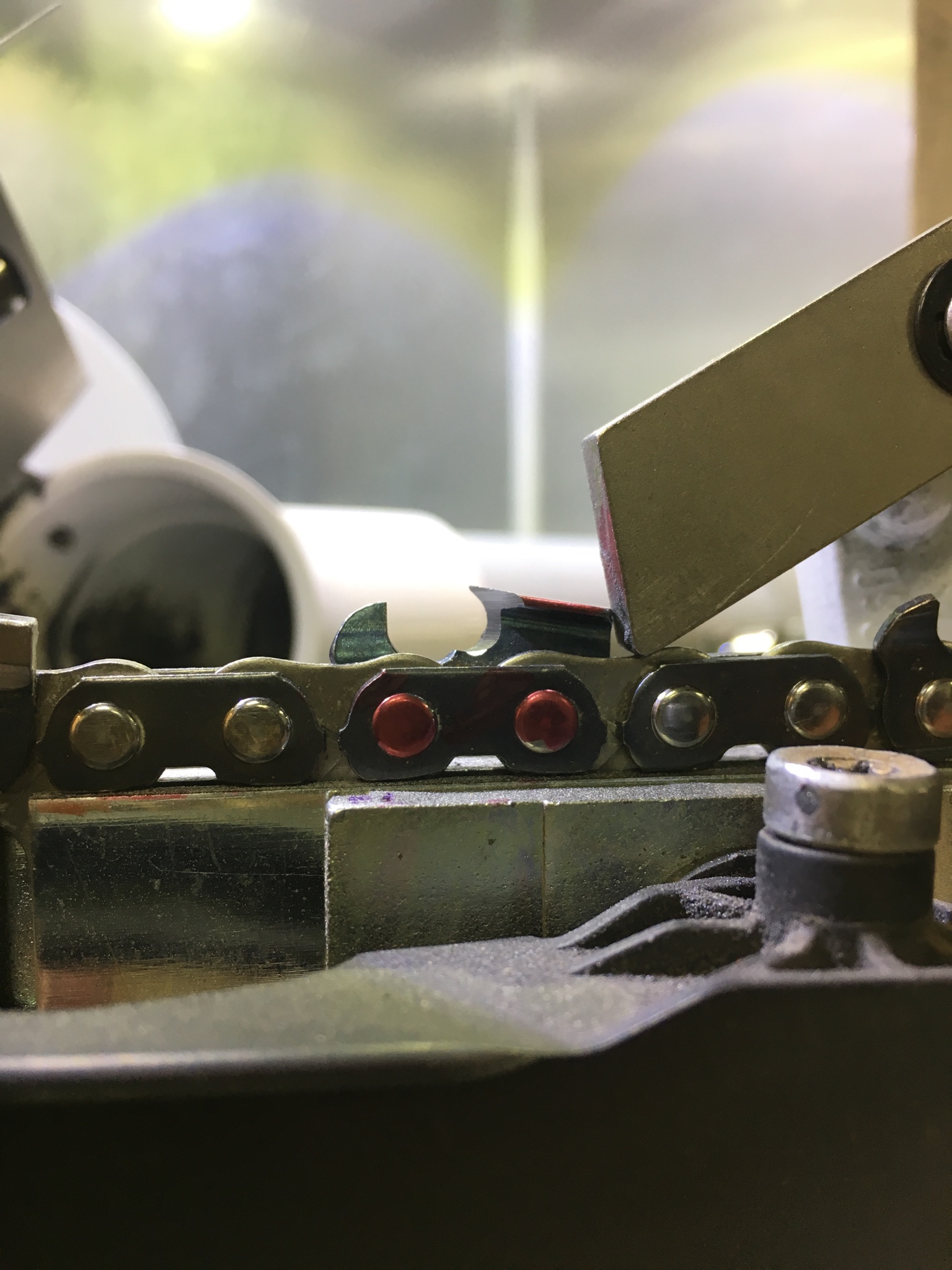

View attachment 572964 View attachment 572965 View attachment 572966 View attachment 572967

.404 205 drive link

Hanging off the floor at 6'10 3/4" and almost touching

Taking a big cut with the diamond wheel and it's rolling the chrome a little but it had a 164 cuts on the chain mounted to a Holtec saw that cuts bundles of lumber

So there is 284 2x4 ina bundle

so 46,500 or or so of 2x4's on this chain https://uploads.tapatalk-cdn.com/20170421/d0747be0d2df45806232d0cbcd3aea03.jpg[/IMG

This is the amount of chain that is under the the grinder knotty up with the rail guides 50 1/2" off the floor

It's a workout for 25$ and still knock the rackers down to .32

Sent from my iPhone using Tapatalk

Wow that will throw some chips!!!.404 205 drive link

Hanging off the floor at 6'10 3/4" and almost touching

Taking a big cut with the diamond wheel and it's rolling the chrome a little but it had a 164 cuts on the chain mounted to a Holtec saw that cuts bundles of lumber

So there is 284 2x4 ina bundle

so 46,500 or or so of 2x4's on this chain https://uploads.tapatalk-cdn.com/20170421/d0747be0d2df45806232d0cbcd3aea03.jpg[/IMG

This is the amount of chain that is under the the grinder knotty up with the rail guides 50 1/2" off the floor

It's a workout for 25$ and still knock the rackers down to .32

Sent from my iPhone using Tapatalk

Looks like you need some kind of 'bogey wheel' to keep things off the floor. Maybe one that is removable when not needed?

View attachment 574345

Philbert

Enter your email address to join: