hedge hog

ArboristSite Guru

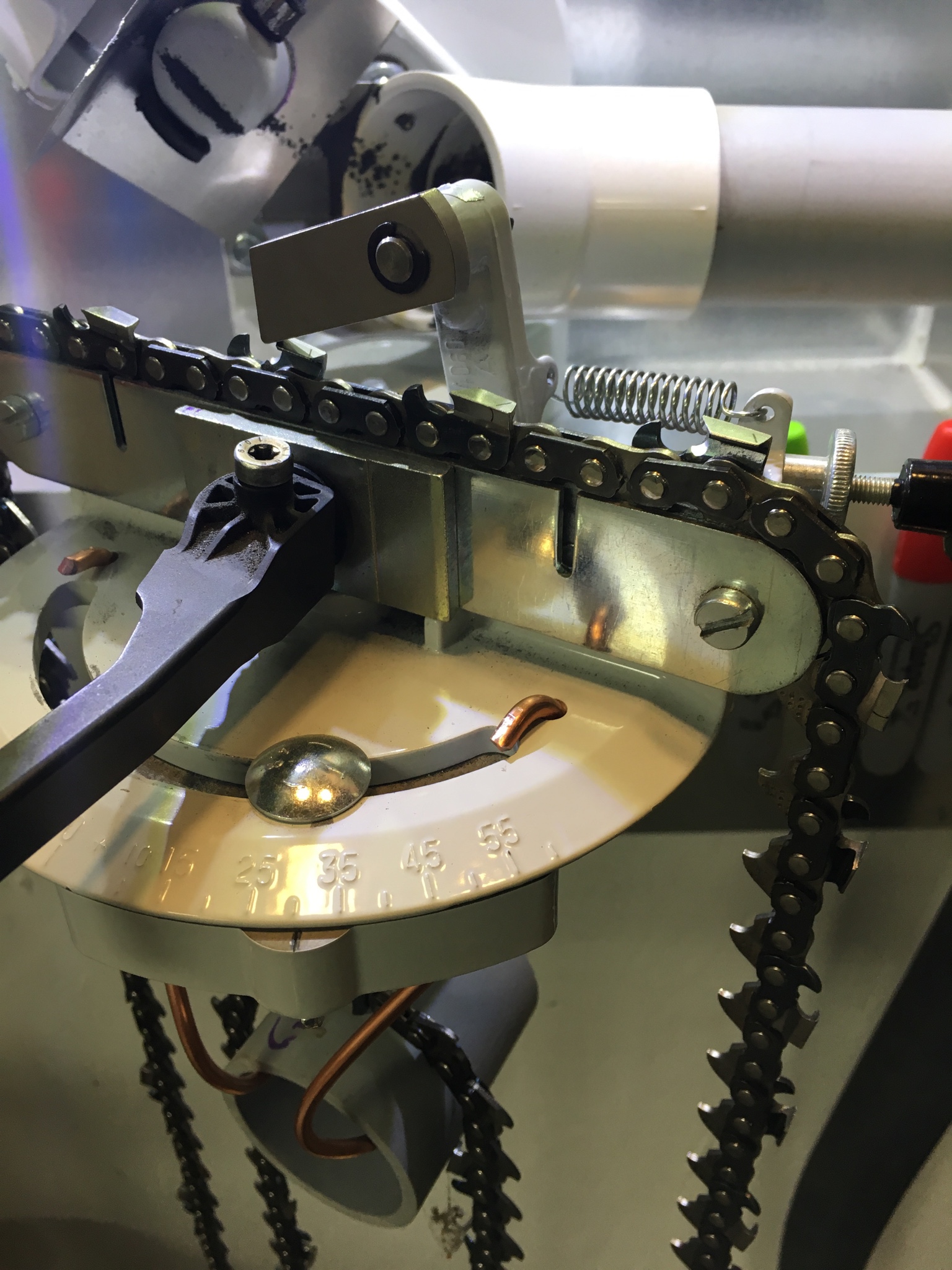

Will tell you that there will be some copper involved and soldering and that # 6 solid will still let me turn the table to 30 degrees but no further

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Will tell you that there will be some copper involved and soldering and that # 6 solid will still let me turn the table to 30 degrees but no further

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

at that price range step into the USG,You got deep pockets go for $500 Oregon one . [emoji106][emoji3]

Sent from my LG-H900 using Tapatalk

I too have one of these and consider it very nearly as good as the 511 oregons which I have two of.

This all you need to make them better then factory . First timers takes about 5 sharpening to get the hang of it . And you'll be on your way .

key point is set vise to 10 degrees ( Oregon chains ) the right way and don't hit the chain links set the the stop down correct . you will say

wow I should of bought one along time ago ... ( that's what I saidand you need to get good at dressing grind wheel to right radius . Gauge and

instructions come with it . only thing was bad in the instructions was they didn't explain the 10 degree vise very well .. otherwise its priceless .

I have 2 one for sharpening and one to set rakers .. Had this style since 2011 ( 90 cord ago ) before that I had cheaper Oregon sharpener with 4 inch wheel .

These are my findings others may differ ..

Woodblocker55

I got another one on special sale $79 crazy thats great deal just wheels would cost that much . It sharped my chains for last 5 years maybe 25 sharpens a year.I too have one of these and consider it very nearly as good as the 511 oregons which I have two of.

I too have one of these and consider it very nearly as good as the 511 oregons which I have two of.

Have you tried it with different wheels to see if there is a performance difference?I do 40 to 50 sharpening a season with my Oregon clone. It took some fussing with (an extra washer underneath) to get the swivel plate to tighten down properly, and then I have never had a single problem with the machine.

Have you tried it with different wheels to see if there is a performance difference?

Philbert

I'm still on my original wheels. They don't wear out lol. Maybe 4 years now . Needs dressing about every 2 sharpenings of a 16 inch chain .

Sent from my LGL84VL using Tapatalk

I only have the ceramic wheels that came with the grinder. The CBN wheels are on my wish list after the ceramic and its replacement wheel dies.

The CBN wheels are suppose to generate less heat for more aggressive metal removal.

I appear to be in the minority, but prefer a well-dressed vitrified (e.g. 'pink') wheel. The CBN wheels I tried generate less dust, but I can still easily overheat a cutter with them. Especially STIHL cutters for some reason.

I have used various 'pink' wheels, and tried a Tecomec 'brown' wheel (the color, of course, is just added, and can vary with manufacturer), along with resinoid wheels:

https://www.arboristsite.com/community/threads/resinoid-grinder-wheels.256733/

One of the biggest differences I noted was replacing a fine, OEM wheel with a coarser, Oregon replacement wheel, when comparing some of the smaller, cheaper grinders:

https://www.arboristsite.com/community/threads/oregon-310-mini-grinder.283691/ (Post #11)

"Tried the replacement wheel today. BIG difference! Almost like comparing a sharp and dull chain. It was so much fun that I grabbed another chain to sharpen!"

Makes sense, right? If a sharp chain makes a big difference on a saw, a better wheel will do the same on a grinder.

Philbert

Enter your email address to join: