MCW

Somebody's talking crap here & it ain't the tree!

While we are talking about pulling trees, I've done a few lately and I think I've got a method down pat. But it's not like I've ever been shown a "correct" way.

Lately I've been getting my pull rope or chain nice and high, cutting a face that gets me a hinge in decent wood and plunge cutting the back cut. Adding a wedge from both sides and then doing the double check with tractor driver and tagging the backstrap.

Getting the pull rope high is obvious, but when a ladder doesn't do the job I've been shooting a throw line up with an APTA - as I throw like forest gump does differential equations.

Face cut depth I've been working with as little as I think I can get away with, mostly these haven't been the most trustworthy trees and all I'm looking for is solid hinge wood.

Plunge cutting the back cut and leaving a holding strap seems good, just gives a minute to double check everything before the noisy bit. Leaves the wedges in a weird spot, but they stop the tree setting back which is all they really need to do.

Anybody else got anything to add? Cos it tends to be something you can't really afford to **** up most of the time.

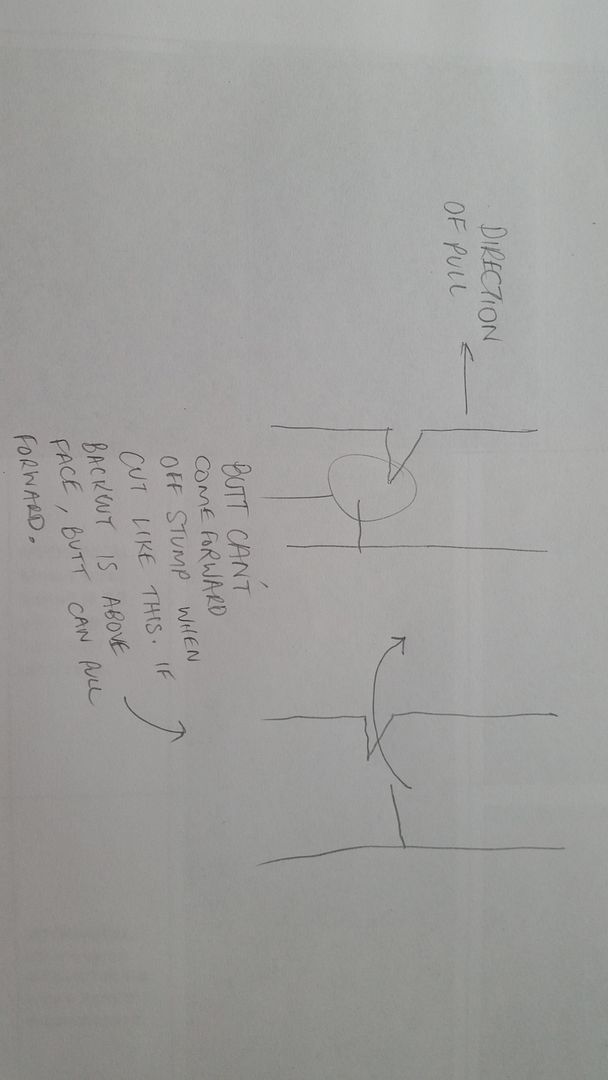

Bring your back cut in below the face in tow over/push over scenarios to avoid the butt spitting off the front of the stump. That's about it.