5100 to the left ??

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Dolmar 7910 - Snellerized Style

- Thread starter blsnelling

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Stihl working hard

Is it Friday yet

Very nice work there BradIt's been 5-6 years since I last modded a Dolmar 7900. I never was quite satisfied with the results I was getting at that time. I've followed MillerModSaws threads very closely. I've talked to Randy and Poleman as well. I owe a lot of this build to them. I've taken what I learned from them and applied it to this new 7910. Thanks guys!

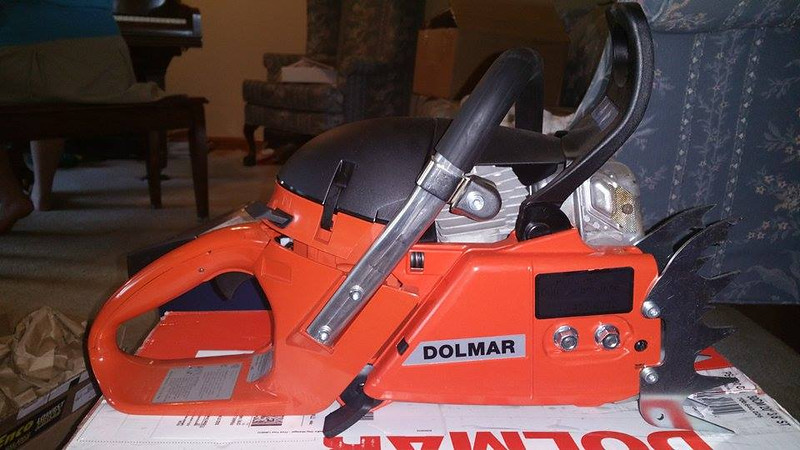

Here's the saw as I received it, straight from our friend FordF150.

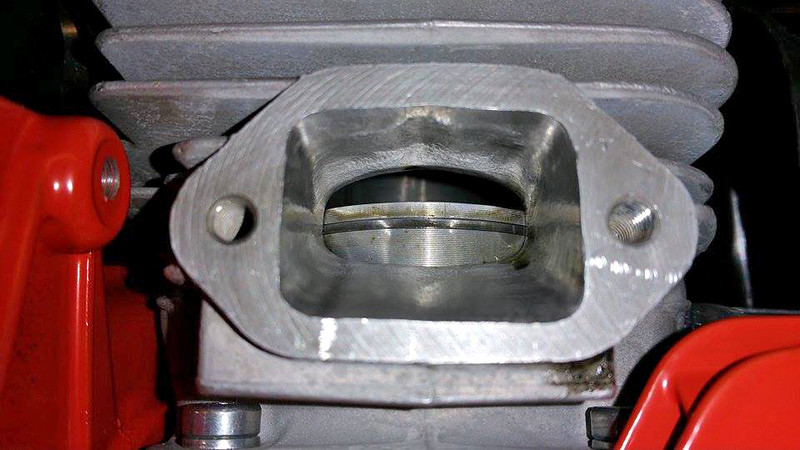

Those of you that have followed some of the other 7910 threads will know that they have a very restrictive chamber in the muffler. This chamber actually protrudes from the muffler and inserts into the exhaust port. The muffler must be uncrimped and this chamber removed. I then cut the chamber and the protrusion from the thick metal flange they're welded to. I ground most of the grooves from the exhaust port. This meant a LOT of port matching on the thick flange of the muffler. Lots of extra work on this saw in the muffler and exhaust port!

Adirondackstihl

Flyz, Fuel & Fotos

What gave that away?5100 to the left ??

If it runs anything like I think it is, I'll be tickled pink.I know your not particularly found of these saws. Has that changed any?

That was the hardest part of this build. Of course, the first time is always the hardest, but it is a lot of work.Good job Brad!!!!! Don't the r's make you grin compared to stock???

You really spent some time on the exhaust.....looks GREAT!!!

Adirondackstihl

Flyz, Fuel & Fotos

Any inside pics?

166

Addicted to ArboristSite

166

Addicted to ArboristSite

Ain't you gotta before pic of "Wally" in the back of the truck?

Adirondackstihl

Flyz, Fuel & Fotos

Deets066

Firewood hack

"I have a potty mouth"What gave that away?

CapitaineHaddoc

European Westcoaster

drf255

BAD CAD

Brad,

The work looks top notch as usual. Port beautiful.

How did you calculate the needed timing on the saw with the coil? Can you give us some insight into the calculations, what the position the magnets need to be on the coil to fire it, etc...

Did you measure where it fired in relation to the flywheel on a 272 first, then make similar alignment of the magnets?

The work looks top notch as usual. Port beautiful.

How did you calculate the needed timing on the saw with the coil? Can you give us some insight into the calculations, what the position the magnets need to be on the coil to fire it, etc...

Did you measure where it fired in relation to the flywheel on a 272 first, then make similar alignment of the magnets?

Wow…ya done really good

benp

Addicted to ArboristSite

Good work as always Brad!!

The ease of tuning was the main reason that I went with the unlimited coils in both of mine.

The ease of tuning was the main reason that I went with the unlimited coils in both of mine.

Can someone explain why the manufactures go with limited coils? Seems to me that an unlimited coil would be cheaper to produce, easier for techs to tune, more reliable since there would be less circuits inside the coil.

Must be a reason since just about every manufacturer is switching to them

Must be a reason since just about every manufacturer is switching to them

If setup too lean they still burn up but don't turn 20k and dismantle themselves explosion style dragging law suits in their wake?!Can someone explain why the manufactures go with limited coils? Seems to me that an unlimited coil would be cheaper to produce, easier for techs to tune, more reliable since there would be less circuits inside the coil.

Must be a reason since just about every manufacturer is switching to them

Poleman

Addicted to ArboristSite

I think it would be for the unskilled tweezers who think a totally leaned saw is faster. I've seen this tim and again on Stihl 044/046's where the saws were tuned to just scream.....while they lasted.

I think it's a way of manufacturers to help their equipment last longer in unskilled hands and reduce warranty work.

Just kinda my thoughts on it.....

Sent from my SAMSUNG-SM-G900A using Tapatalk

I think it's a way of manufacturers to help their equipment last longer in unskilled hands and reduce warranty work.

Just kinda my thoughts on it.....

Sent from my SAMSUNG-SM-G900A using Tapatalk

I do not. It's sporting a .020" popup and cylinder base cut. Porting was a combination of what Miller and MM do, with a little of my own flair added in.Any inside pics?

Here's how I do it. http://www.arboristsite.com/community/threads/how-to-make-your-7900-or-681-non-rev-limited.116556/Brad,

The work looks top notch as usual. Port beautiful.

How did you calculate the needed timing on the saw with the coil? Can you give us some insight into the calculations, what the position the magnets need to be on the coil to fire it, etc...

Did you measure where it fired in relation to the flywheel on a 272 first, then make similar alignment of the magnets?

Paragon Builder

AS Enthusiast

- Joined

- Nov 27, 2014

- Messages

- 3,029

- Reaction score

- 3,078

Hey Brad, I just read through that thread. You mentioned you adjust timing until you achieve max rpm. Is this how you find the best timing on all saws? Is this a safe way to do it? And besides rpm starting to drop, how do you or I know it's got too much advance? I always wondered when advancing my saws if I would know if it was too much by how it ran, or if I'd find out when I cooked it?[emoji12]

Hasn't stopped me though!

Hasn't stopped me though!

I was advised to set this saw to 30*, which I did. Throttle response is lightning quick and it runs great. I let someone else do the homework on this one

Similar threads

- Replies

- 46

- Views

- 2K

- Replies

- 10

- Views

- 2K

Latest posts

-

-

-

Stihl FS-130z Trimmer C1Q-S173 Carburetor Settings

- Latest: Huskyvarnya Saws

-

-

-

-

-

Scrounging Firewood (and other stuff)

- Latest: MechanicMatt