I've been keeping this build under wraps until I knew it'd at least run. I've never been so nervous in my life to fire up a fresh build. I tried a bunch of new things I'd never done before.

First of all, Jacob J gets a big THANK YOU for helping out as technical advisor for the build. He built a couple like this several years ago, and they're still in service today as milling saws.

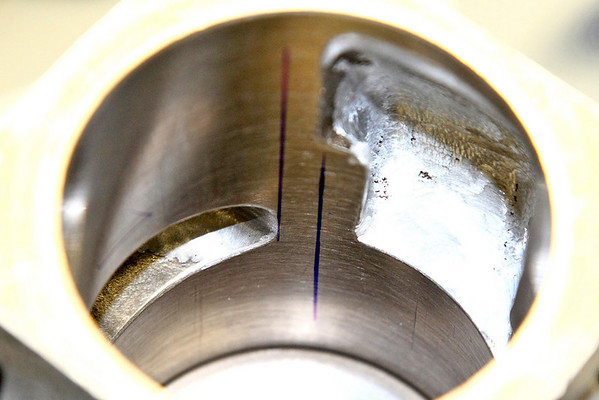

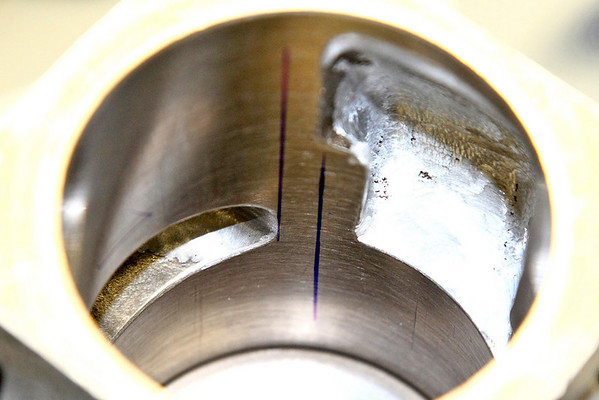

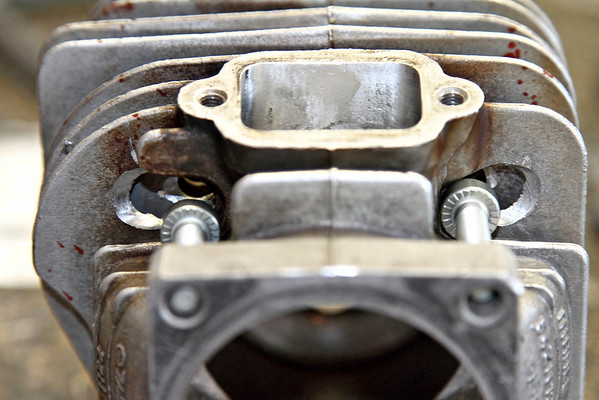

This cylinder is the one I used for the Wiseco testing. The skirts being a little wider on that piston, the ports ended up too wide for a standard 066 piston. So I asked JJ if he knew of a piston that might work. The answer was a Husky 385XP piston. But it's not just a dropin replacement. The 385 piston is significantly taller.

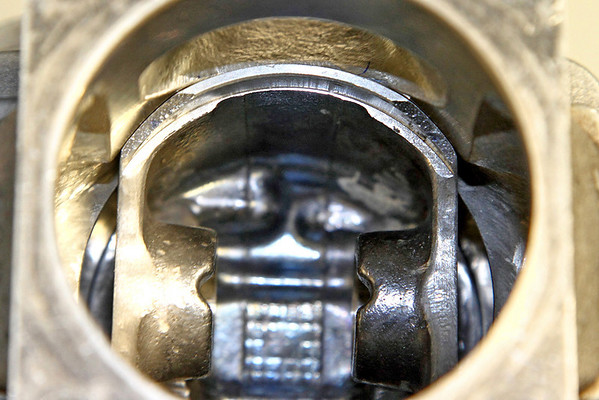

I started with a .048" popup, taking the crown down to .090" thin...I mean thick, lol. Thanks to Nik for again doing a great job! I also "flattened" the side of the piston and put windows in it.

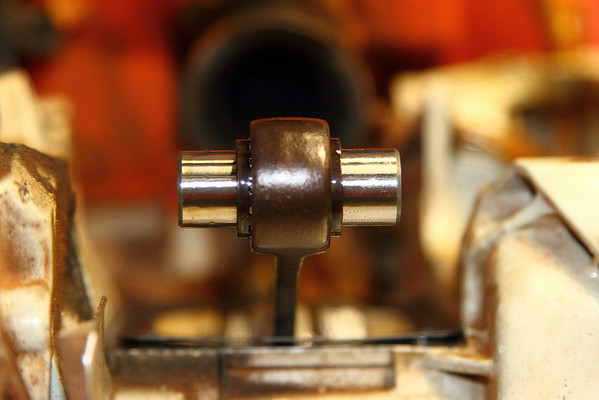

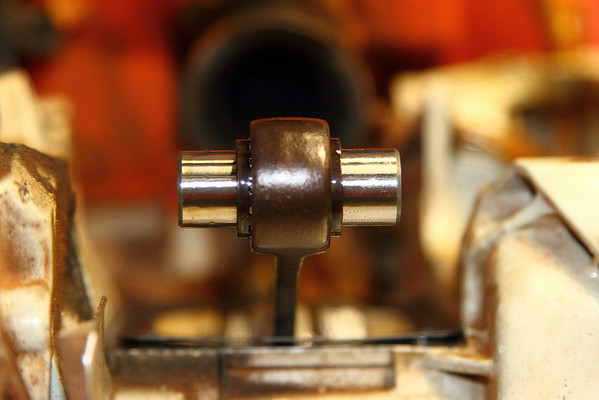

The rod IDs are the same, but the 385 wrist pin is larger. That means you have to use the wrist pin bearing and pin for the 385.

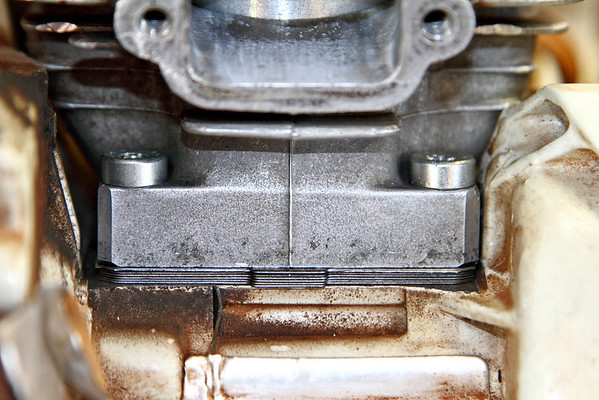

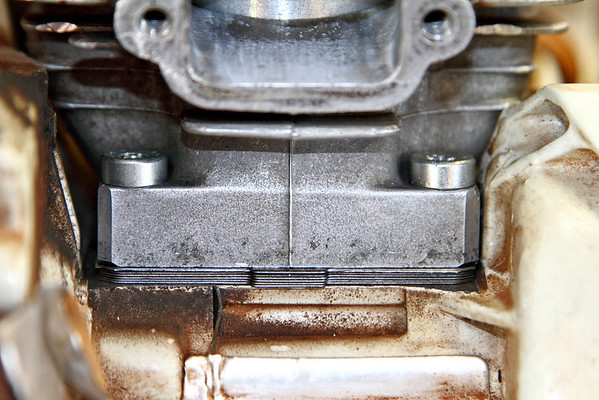

I then had to space up the cylinder. I ended up using 6 OEM gaskets and one made of .005" pop can aluminum. The total was about .110". I crushed each factory gasket individually in order to flatten out the raised portion. I didn't think it wise to try to do them all at once.

Even after spacing up the cylinder, I still could not run the bottom ring. I may go back in at a later time and relocate the ring locating pin inbetween the exhaust and transfer. So for now, it's only running one ring.

First of all, Jacob J gets a big THANK YOU for helping out as technical advisor for the build. He built a couple like this several years ago, and they're still in service today as milling saws.

This cylinder is the one I used for the Wiseco testing. The skirts being a little wider on that piston, the ports ended up too wide for a standard 066 piston. So I asked JJ if he knew of a piston that might work. The answer was a Husky 385XP piston. But it's not just a dropin replacement. The 385 piston is significantly taller.

I started with a .048" popup, taking the crown down to .090" thin...I mean thick, lol. Thanks to Nik for again doing a great job! I also "flattened" the side of the piston and put windows in it.

The rod IDs are the same, but the 385 wrist pin is larger. That means you have to use the wrist pin bearing and pin for the 385.

I then had to space up the cylinder. I ended up using 6 OEM gaskets and one made of .005" pop can aluminum. The total was about .110". I crushed each factory gasket individually in order to flatten out the raised portion. I didn't think it wise to try to do them all at once.

Even after spacing up the cylinder, I still could not run the bottom ring. I may go back in at a later time and relocate the ring locating pin inbetween the exhaust and transfer. So for now, it's only running one ring.

Last edited:

You really think that 084 is still stock:greenchainsaw: Nah baby nah

You really think that 084 is still stock:greenchainsaw: Nah baby nah