stinkbait

Addicted to ArboristSite

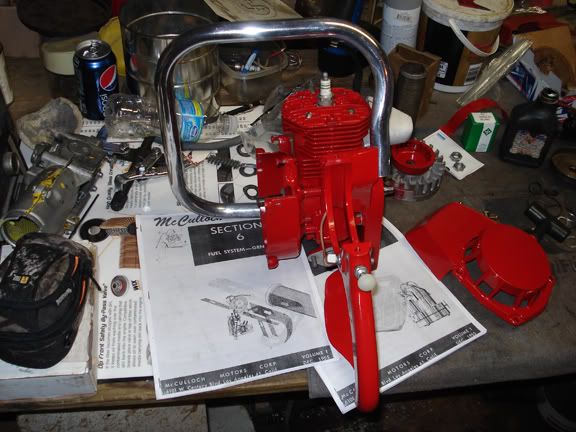

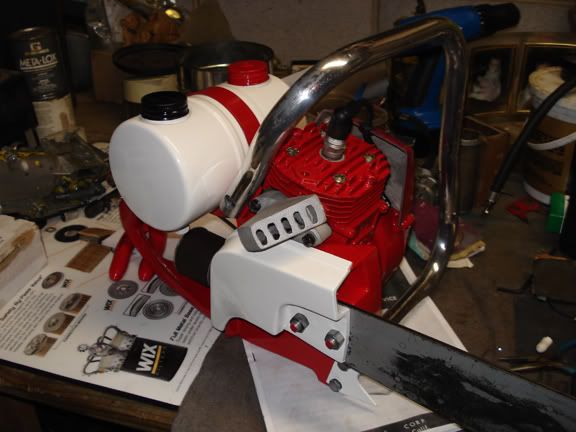

I got the crank case pressed together today on my lunch break. My girlfriend's dad works at a machine shop and he did it for me. I wish that I had a press and a few other tools so that I could do it myself. I will install the piston, rings, head, intake, and handle tonight and post some pics in the morning.