Four Paws

Addicted to ArboristSite

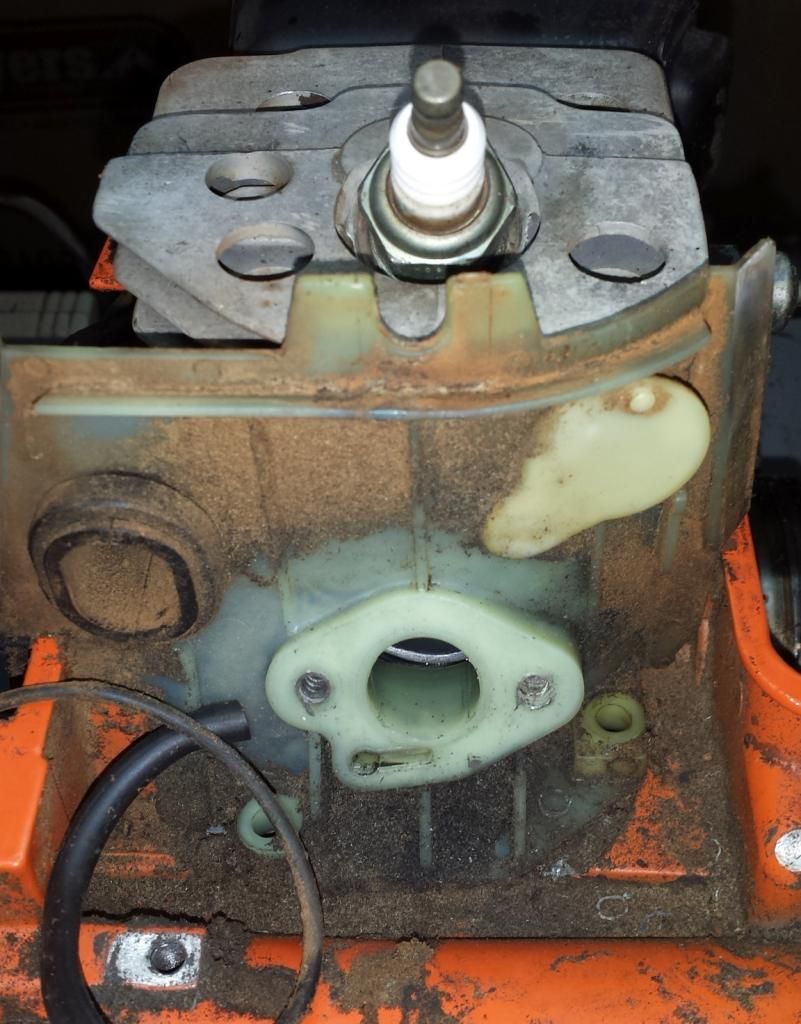

There has been some recent press surrounding the 46mm Meteor Piston and Cylinder kit for the Husqvarna 50/51/55. I had a burned down Closed Port 55 donated to me by a good friend. As such, I decided it would be a good time to build this saw using the 46mm Meteor kit and provide an honest review of the product quality and out of the box performance.

I also want this thread to encourage the aspiring do-it-yourselfer to take the leap and build (or rebuild) their very first saw. The 50/51/55 is a great platform for several reasons.

1. They are plentiful (which makes them cheap).

2.They have a simple design.

3.They have a vertically split magnesium crankcase.

4. Parts availability is excellent.

5. They make a good firewood saw.

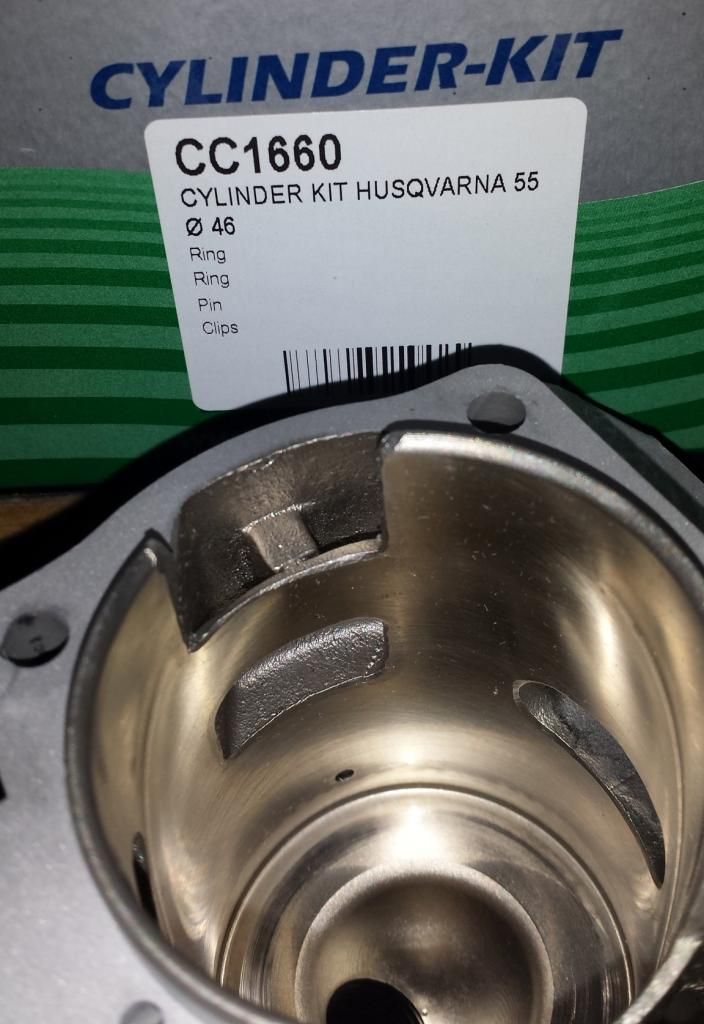

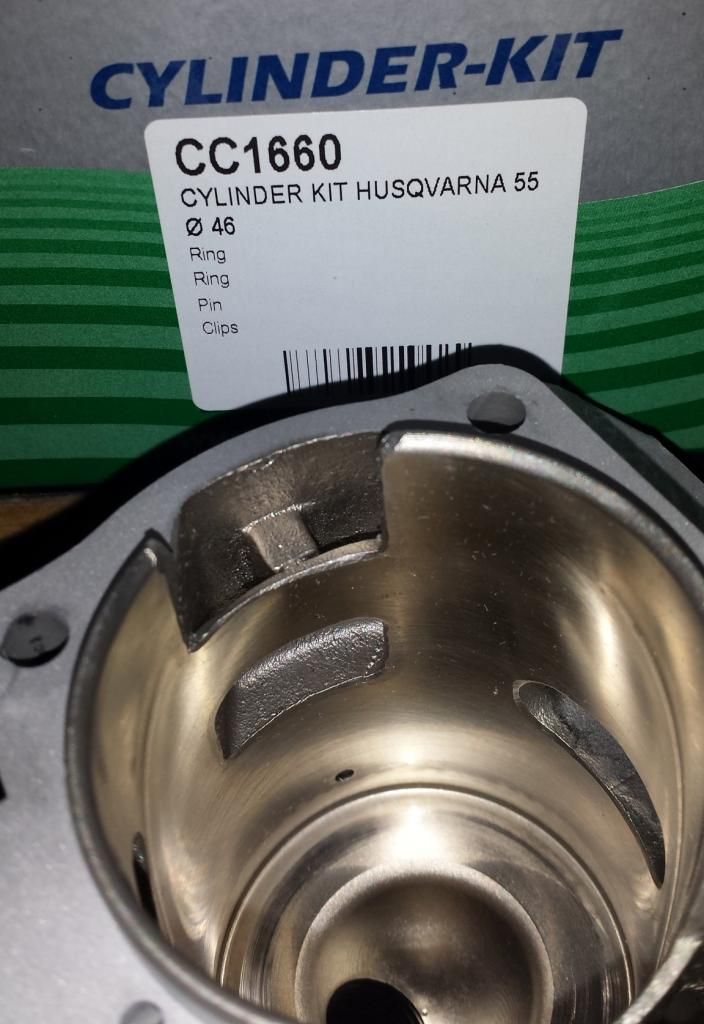

First up, the kit. I am a savvy shopper and checked around for the best price using google. SawSalvage.com run by our very own site sponsor Duke Thieroff had it locked down at $135 shipped to my door. My package arrived via USPS Priority Mail in 3 days. Packaging was first rate.

Unboxed, here is what you get. A beautiful piston with Caber ring. Externally, the cylinder retains the provision for the decomp valve.

Internally, you can see the beautiful plating, nicely shaped combustion chamber and the transfer and exhaust port in the next photo.

In the thread below, another member said he is suprised that nobody has compared the OEM closed port timing numbers to the 46mm Meteor kit. Well, stick with me and I'll have an answer for you, as I plan to do just that in the days to come!

http://www.arboristsite.com/communi...ds-available-from-meteor.270734/#post-5168581

I also want this thread to encourage the aspiring do-it-yourselfer to take the leap and build (or rebuild) their very first saw. The 50/51/55 is a great platform for several reasons.

1. They are plentiful (which makes them cheap).

2.They have a simple design.

3.They have a vertically split magnesium crankcase.

4. Parts availability is excellent.

5. They make a good firewood saw.

First up, the kit. I am a savvy shopper and checked around for the best price using google. SawSalvage.com run by our very own site sponsor Duke Thieroff had it locked down at $135 shipped to my door. My package arrived via USPS Priority Mail in 3 days. Packaging was first rate.

Unboxed, here is what you get. A beautiful piston with Caber ring. Externally, the cylinder retains the provision for the decomp valve.

Internally, you can see the beautiful plating, nicely shaped combustion chamber and the transfer and exhaust port in the next photo.

In the thread below, another member said he is suprised that nobody has compared the OEM closed port timing numbers to the 46mm Meteor kit. Well, stick with me and I'll have an answer for you, as I plan to do just that in the days to come!

http://www.arboristsite.com/communi...ds-available-from-meteor.270734/#post-5168581