Canyon Angler

Addicted to ArboristSite

Hey, all,

I just bought a pair of Carolina Boots #821 which I believe is also sold by Madsens as their "Value Logger."

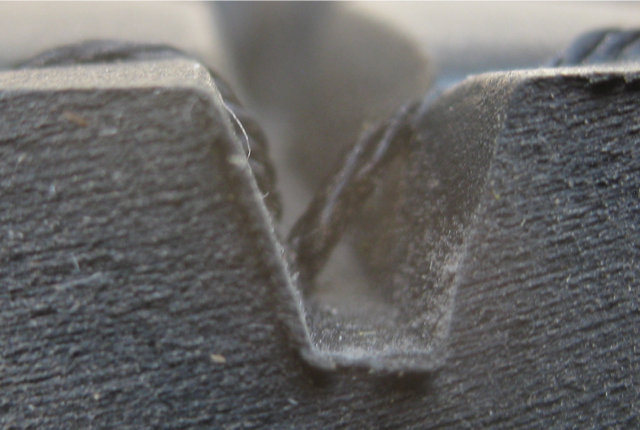

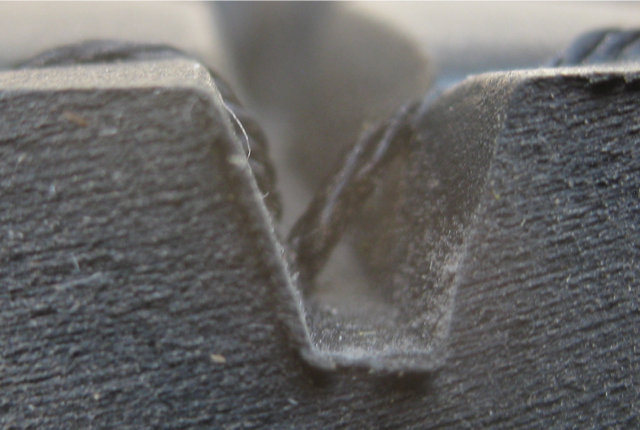

Tried them on and they fit fine and everything, but looking them over, I noticed that the string used to sew the outsole to the insole at the toe is exposed between the lugs of the outsole. The cord basically "bridges" the gaps between the lugs in several places. See below:

My concern is that when these "strings" wear through and break – and I don't think it will take long – then the outsole will no longer be sewn to the insole...and I've seen what happens when you rely only on glue alone. You start tripping over your own boot sole when it folds back under your heel.

Not sure what stitch is used to attach the outsoles on these boots, but I've used a jerk needle to sew outsoles back onto boots when the glue has failed, and I know that if any of those strings broke, then the whole "seam" would pretty quickly come undone.

What do you boys think? Would you consider this Vietnamese sewing job to be defective? Would you return the boots and ask for a pair that were sewn "correctly," assuming these aren't? (I can't afford Wescos/Red Wings/Chippewas/etc.)

Thanks for any opinions...

I just bought a pair of Carolina Boots #821 which I believe is also sold by Madsens as their "Value Logger."

Tried them on and they fit fine and everything, but looking them over, I noticed that the string used to sew the outsole to the insole at the toe is exposed between the lugs of the outsole. The cord basically "bridges" the gaps between the lugs in several places. See below:

My concern is that when these "strings" wear through and break – and I don't think it will take long – then the outsole will no longer be sewn to the insole...and I've seen what happens when you rely only on glue alone. You start tripping over your own boot sole when it folds back under your heel.

Not sure what stitch is used to attach the outsoles on these boots, but I've used a jerk needle to sew outsoles back onto boots when the glue has failed, and I know that if any of those strings broke, then the whole "seam" would pretty quickly come undone.

What do you boys think? Would you consider this Vietnamese sewing job to be defective? Would you return the boots and ask for a pair that were sewn "correctly," assuming these aren't? (I can't afford Wescos/Red Wings/Chippewas/etc.)

Thanks for any opinions...