Woodplayer

ArboristSite Member

I thought I'd run this problem by you guys since likely someone has experienced a similar problem with an oil pump.

The saw is a Homelite XL-2 (50059) and was just inherited by my neighbour who asked me to have a look at some of the saws he was given.

I noticed originally that the saw was covered in oil (especially inside the muffler), so I cleaned it up good, checked compression and spark,

cleaned out the fuel and oil tanks, adjusted/cleaned the points, took the carb apart and cleaned. It's in really good shape.

I started after only about 6 pulls (it needed to draw fuel back up the fuel line after emptying the tank) and ran good, except for the idle, but smoked alot, with oil virtually running out the exhaust even after ten minutes of running. It appeared that it was burning the chain oil, so I pulled the delivery tube out of the oil tank and after a minute it ran perfectly and idled well, with no smoke.

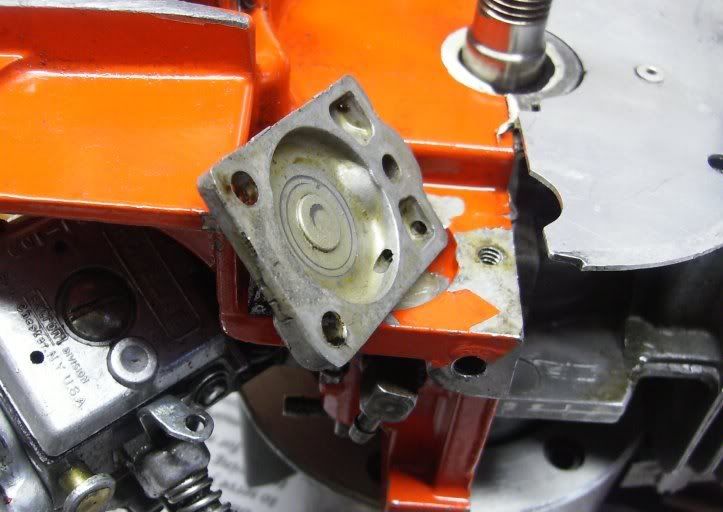

I've attached a few photos of what I found and was hoping someone has an IPL or can figure the correct location for the oil lines.

It appears to have original lines which are in good shape and don't leak.

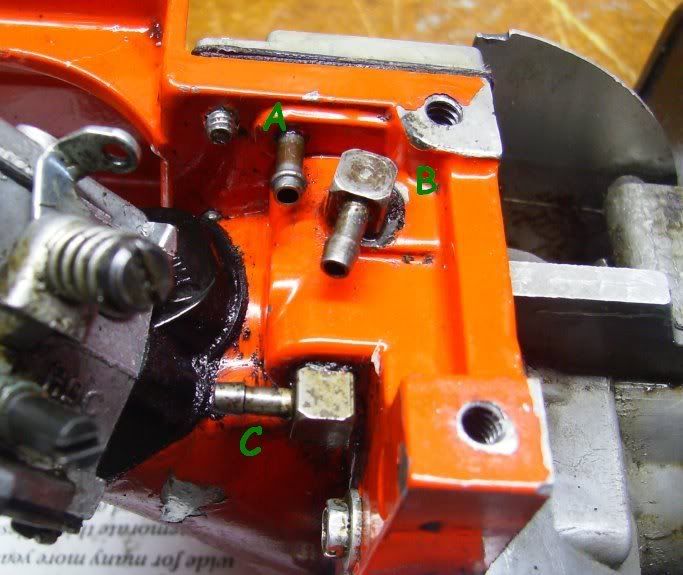

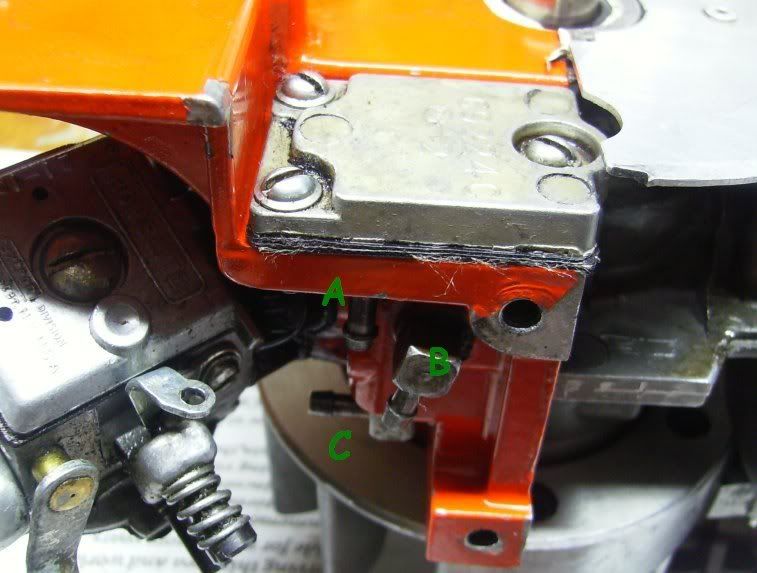

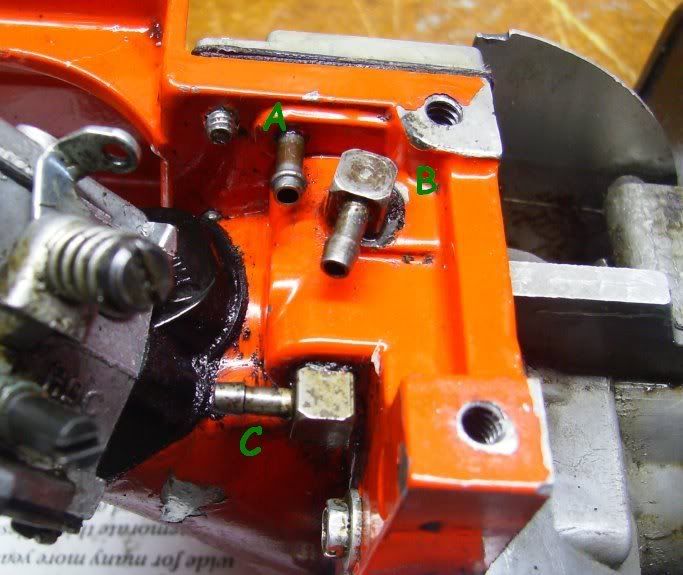

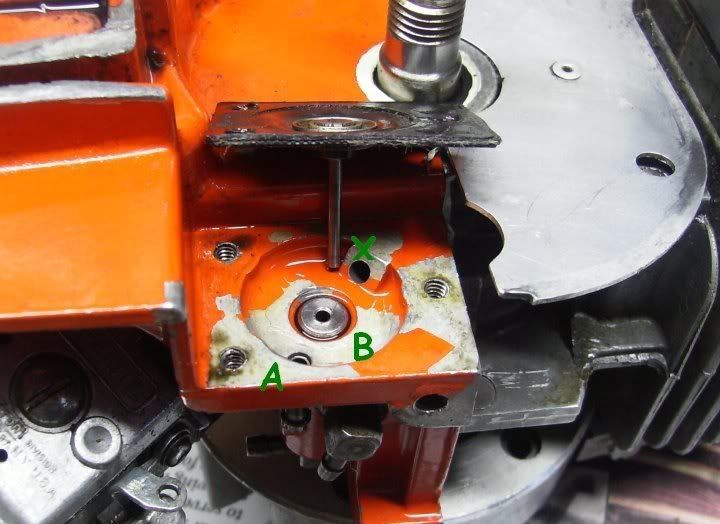

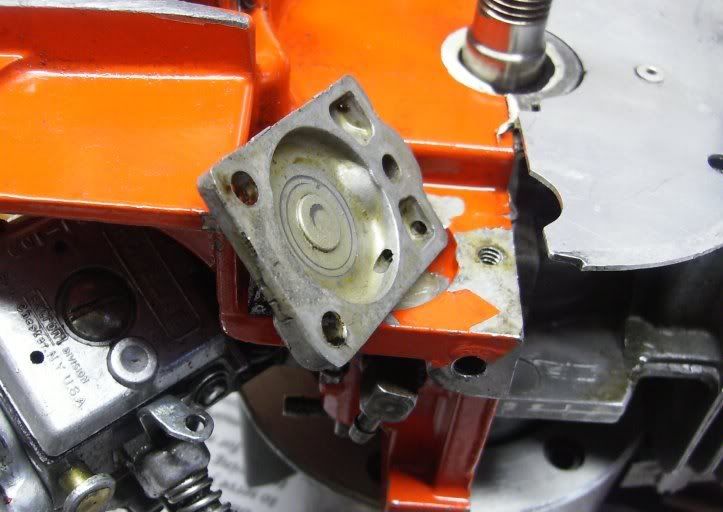

The delivery line from the oil tank goes to spigot A, the vent line from the oil tank goes to spigot B and the line which feeds the bar goes on spigot C.

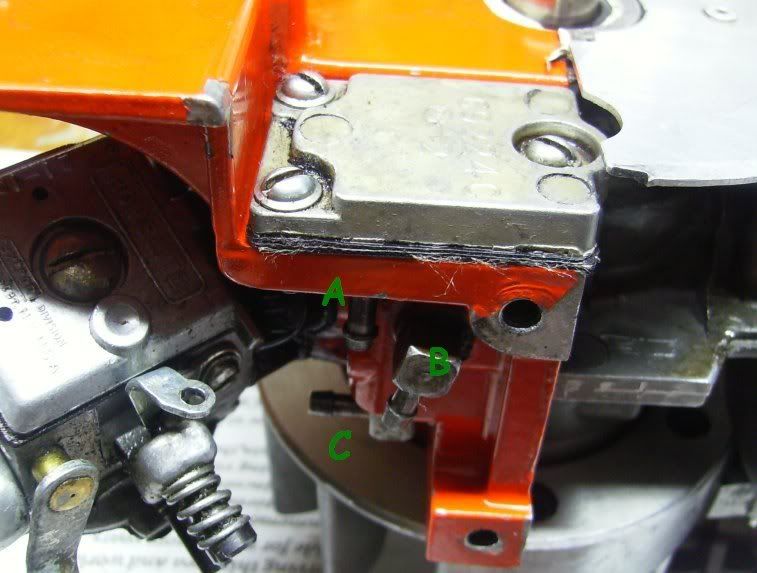

As you can see by the photos, A goes straight through into the bottom of the pump, B comes out the hole where the shaft attached the the diaphram

goes into. I don't know where the "C" spigot goes as I cannot blow or draw air through it. That is my other concern

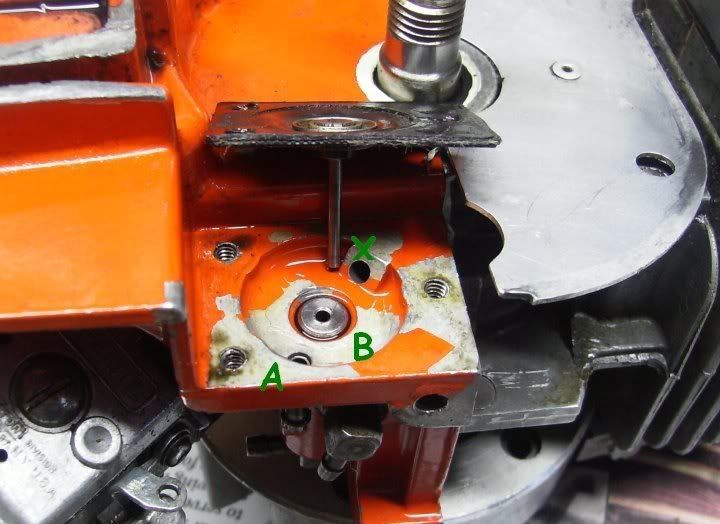

The hole marked "X" appears to go into the crankcase and this is likely where the oil is being drawn into the engine.

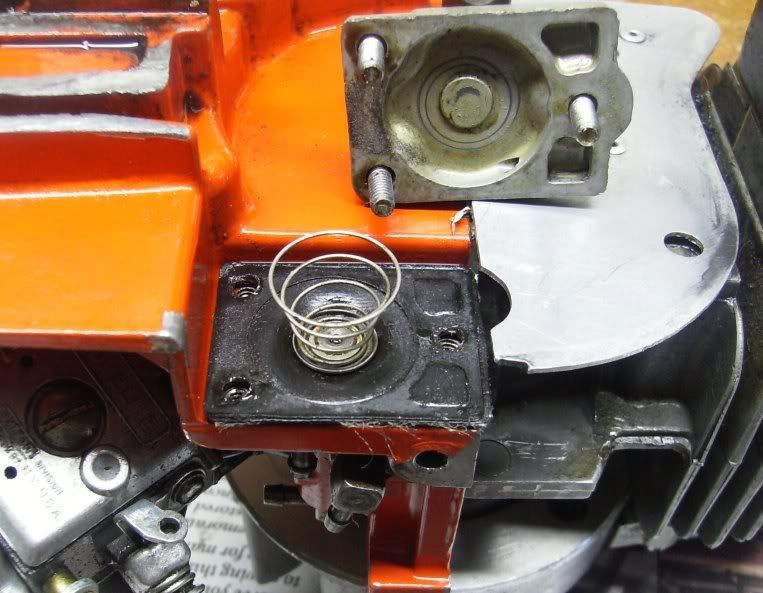

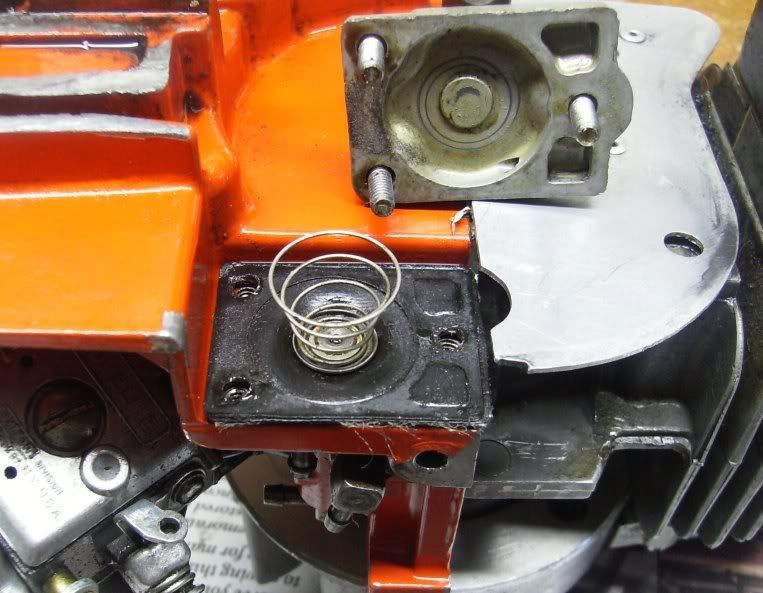

The way I would think the pump should work is that the delivery line should be connected to spigot B and then the pressure pulses from the crankcase

hole should push the diaphram up, which would allow oil to flow into the pump, then out spigot A which should go to the bar. The spring would force the diaphram down during the vacuum draw from the crankcase, to prevent oil from being sucked into the engine. I guess the oil vent line would go onto spigot C?

If I was to connect the lines the way I described I would need to install new lines as the lengths aren't right, which makes me think that perhaps I am not understanding how the pump works, then again maybe someone else had incorrectly installed these lines???

The saw is a Homelite XL-2 (50059) and was just inherited by my neighbour who asked me to have a look at some of the saws he was given.

I noticed originally that the saw was covered in oil (especially inside the muffler), so I cleaned it up good, checked compression and spark,

cleaned out the fuel and oil tanks, adjusted/cleaned the points, took the carb apart and cleaned. It's in really good shape.

I started after only about 6 pulls (it needed to draw fuel back up the fuel line after emptying the tank) and ran good, except for the idle, but smoked alot, with oil virtually running out the exhaust even after ten minutes of running. It appeared that it was burning the chain oil, so I pulled the delivery tube out of the oil tank and after a minute it ran perfectly and idled well, with no smoke.

I've attached a few photos of what I found and was hoping someone has an IPL or can figure the correct location for the oil lines.

It appears to have original lines which are in good shape and don't leak.

The delivery line from the oil tank goes to spigot A, the vent line from the oil tank goes to spigot B and the line which feeds the bar goes on spigot C.

As you can see by the photos, A goes straight through into the bottom of the pump, B comes out the hole where the shaft attached the the diaphram

goes into. I don't know where the "C" spigot goes as I cannot blow or draw air through it. That is my other concern

The hole marked "X" appears to go into the crankcase and this is likely where the oil is being drawn into the engine.

The way I would think the pump should work is that the delivery line should be connected to spigot B and then the pressure pulses from the crankcase

hole should push the diaphram up, which would allow oil to flow into the pump, then out spigot A which should go to the bar. The spring would force the diaphram down during the vacuum draw from the crankcase, to prevent oil from being sucked into the engine. I guess the oil vent line would go onto spigot C?

If I was to connect the lines the way I described I would need to install new lines as the lengths aren't right, which makes me think that perhaps I am not understanding how the pump works, then again maybe someone else had incorrectly installed these lines???