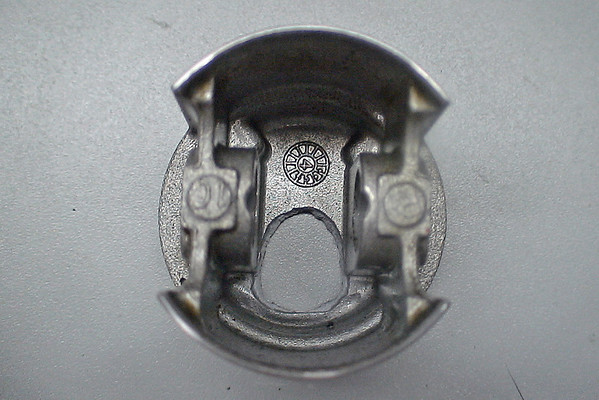

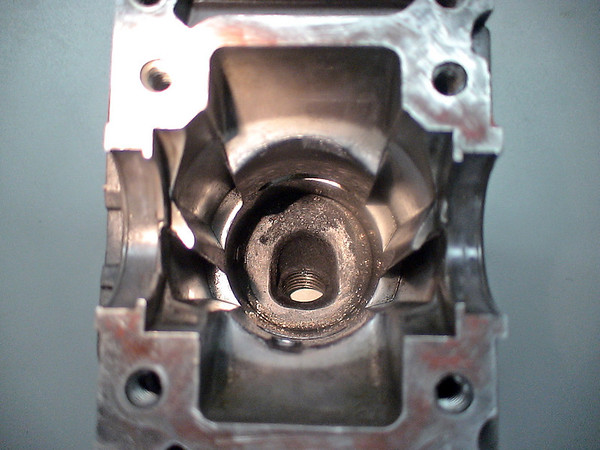

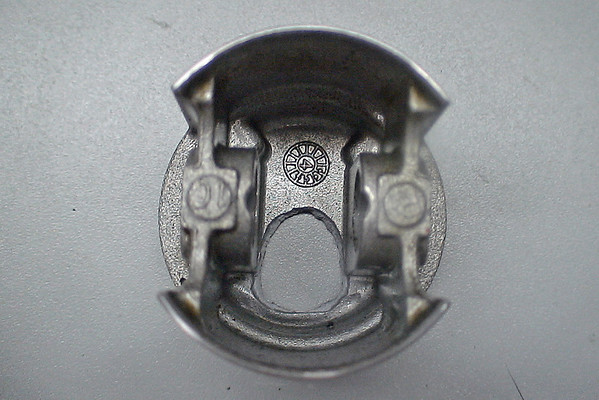

It's time to do the deed. I'm happy with the way the stock engine is running on the adjustable WT215 carb. It only took about 25 minutes or less to get the saw apart. But Ultra, ya jinxed me!! I just ruined my first piston. I screwed my plastic piston stop into the jug and put the wrench on the flywheel nut. It went right through the crown of the piston. The crazy thing was only .075" thick! This piston was in great shape too. Oh well, a tiny piston like that can't be too pricey. I can still proceed with the port work on the jug. Now Ultra, where's that piston already? I need it same day delivery

I just ruined my first piston. I screwed my plastic piston stop into the jug and put the wrench on the flywheel nut. It went right through the crown of the piston. The crazy thing was only .075" thick! This piston was in great shape too. Oh well, a tiny piston like that can't be too pricey. I can still proceed with the port work on the jug. Now Ultra, where's that piston already? I need it same day delivery You know I like to finish my jobs before I start them!

You know I like to finish my jobs before I start them!

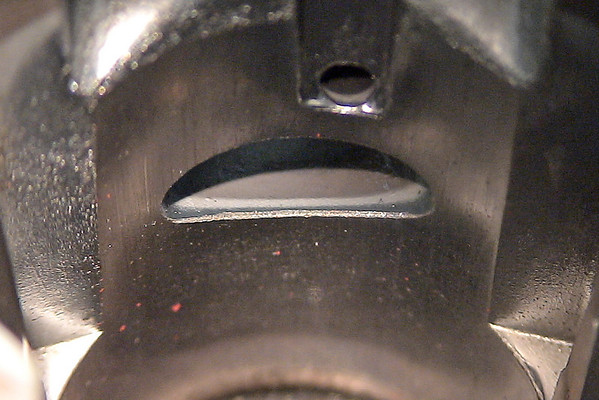

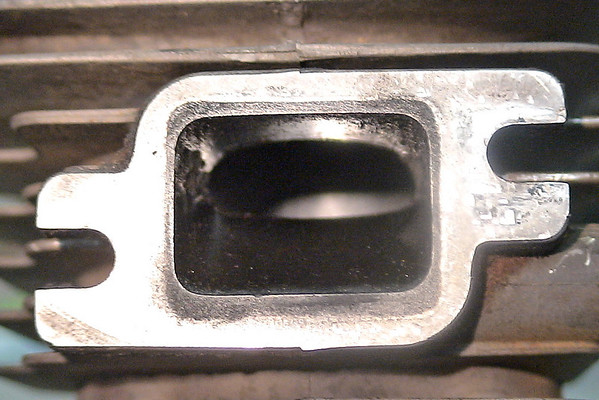

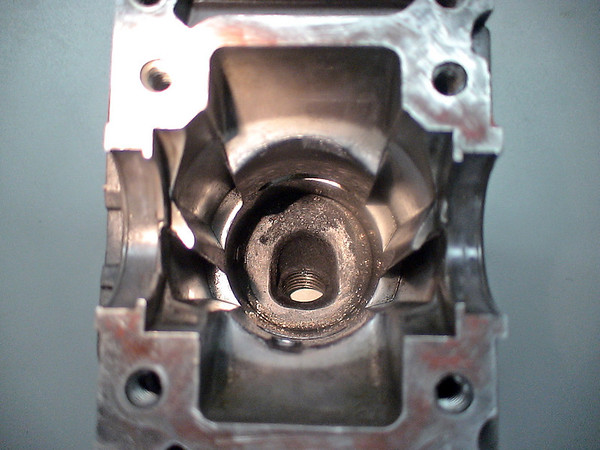

Check out all the black carbon. The combustion chamber looks similiar. So much for thinking these little things are way too lean!

I just ruined my first piston. I screwed my plastic piston stop into the jug and put the wrench on the flywheel nut. It went right through the crown of the piston. The crazy thing was only .075" thick! This piston was in great shape too. Oh well, a tiny piston like that can't be too pricey. I can still proceed with the port work on the jug. Now Ultra, where's that piston already? I need it same day delivery

I just ruined my first piston. I screwed my plastic piston stop into the jug and put the wrench on the flywheel nut. It went right through the crown of the piston. The crazy thing was only .075" thick! This piston was in great shape too. Oh well, a tiny piston like that can't be too pricey. I can still proceed with the port work on the jug. Now Ultra, where's that piston already? I need it same day delivery

Check out all the black carbon. The combustion chamber looks similiar. So much for thinking these little things are way too lean!