So I have this old (12-15 yrs) 021 that has served as an occasional firewood saw -- the trouble started when I loaned it out. Fast forward 2 years, I have the saw back and, I quote, "it doesn't start". I love my in-laws, I really do.

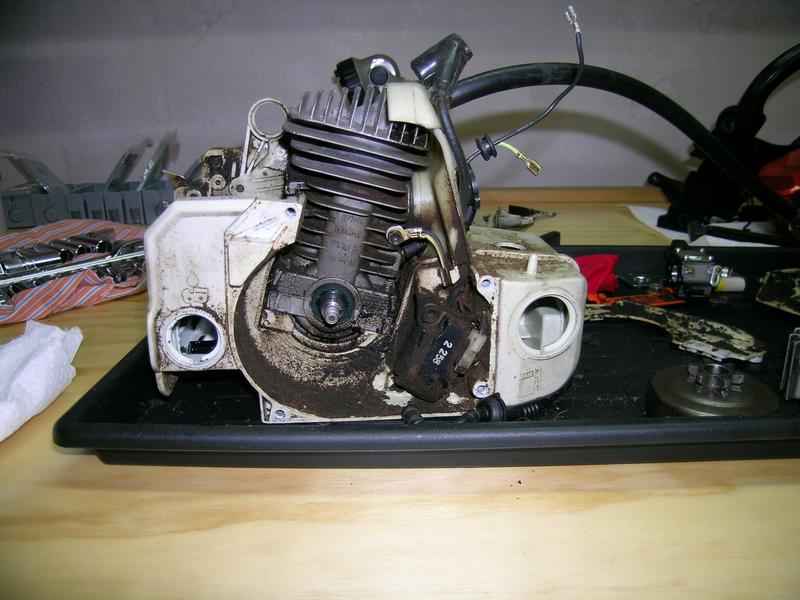

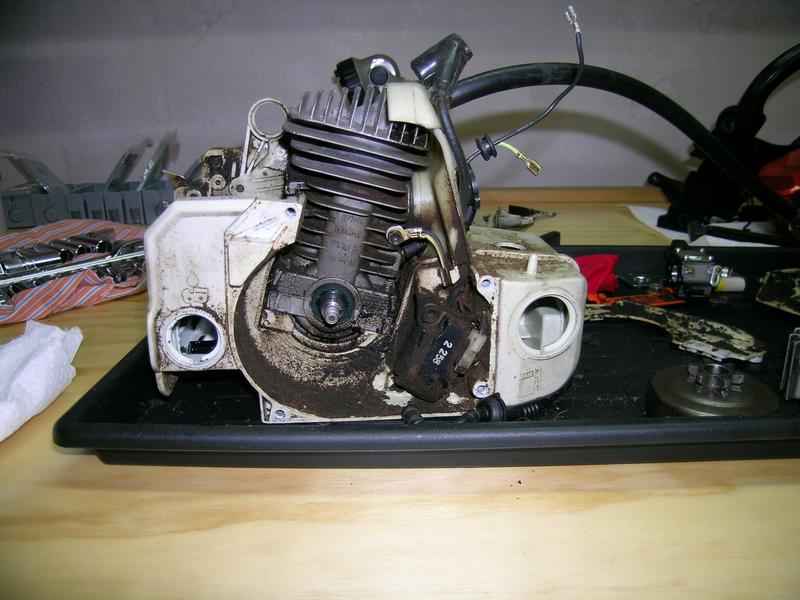

In the tank was ancient 50:1 mix, and the bar and chain, although turned over once in a while, are both in bad shape. The amount of caked-on dirt and grime was interesting.

I have decided to make a small project out of this saw and put it back in running order.

So far I have found a lot of wear and tear; apparently the reason it does not start is either the cracks in the fuel line and/or the cracks in the impulse line.

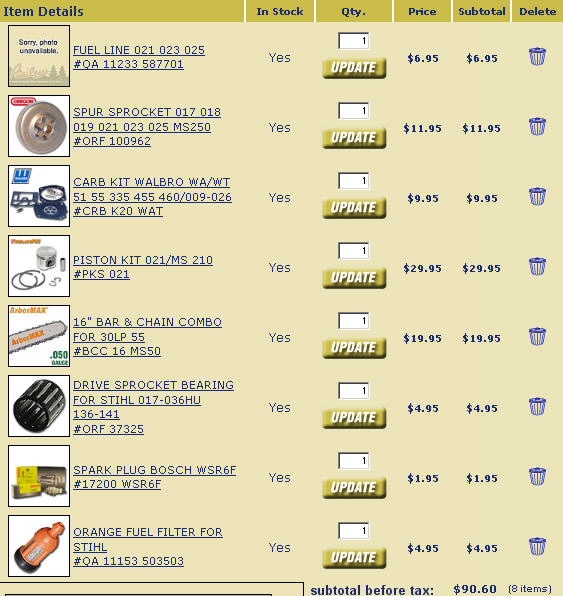

I am going to purchase the following at the parts counter:

- fuel filter

- fuel line

- impulse line

- Walbro carb rebuild kit (Ebay?)

- spark plug

- sprocket (OEM)

- bar/chain combo (Bailey's inexpensive Arborist setup)

The question now is "how far do I go in?"

I compression-tested it (obviously cold) and it came up to 125psi before the flywheel un-keyed itself. (Aside, I tried gently for 5 minutes to get the flywheel off without a puller, but after about 8-10 yanks on the starter cable it came right off). I will put the flywheel back in place with the nut and see if a little more compression is there.

Through the exhaust and inlet ports there is no visible scuffing or damage to the piston.

Based on the above, I'm inclined not to take the jug off and go all the way down to the guts.

Finally, what's the best way to clean the motor assembly itself of all of the accumulated grease, dirt, grime, and other debris?

Ideas? Opinions? Suggestions?

Thanks,

Jim / Wrooster

In the tank was ancient 50:1 mix, and the bar and chain, although turned over once in a while, are both in bad shape. The amount of caked-on dirt and grime was interesting.

I have decided to make a small project out of this saw and put it back in running order.

So far I have found a lot of wear and tear; apparently the reason it does not start is either the cracks in the fuel line and/or the cracks in the impulse line.

I am going to purchase the following at the parts counter:

- fuel filter

- fuel line

- impulse line

- Walbro carb rebuild kit (Ebay?)

- spark plug

- sprocket (OEM)

- bar/chain combo (Bailey's inexpensive Arborist setup)

The question now is "how far do I go in?"

I compression-tested it (obviously cold) and it came up to 125psi before the flywheel un-keyed itself. (Aside, I tried gently for 5 minutes to get the flywheel off without a puller, but after about 8-10 yanks on the starter cable it came right off). I will put the flywheel back in place with the nut and see if a little more compression is there.

Through the exhaust and inlet ports there is no visible scuffing or damage to the piston.

Based on the above, I'm inclined not to take the jug off and go all the way down to the guts.

Finally, what's the best way to clean the motor assembly itself of all of the accumulated grease, dirt, grime, and other debris?

Ideas? Opinions? Suggestions?

Thanks,

Jim / Wrooster